High-strength high-rigidity graphene modified polypropylene and preparation method therefor

A graphene-modified, high-strength technology, applied in the field of modified polypropylene, high-strength and high-rigidity graphene-modified polypropylene, can solve the problems of low dimensional stability, shortened service life, reduced strength, etc., and achieve bending strength High, improved strength and rigidity, good rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

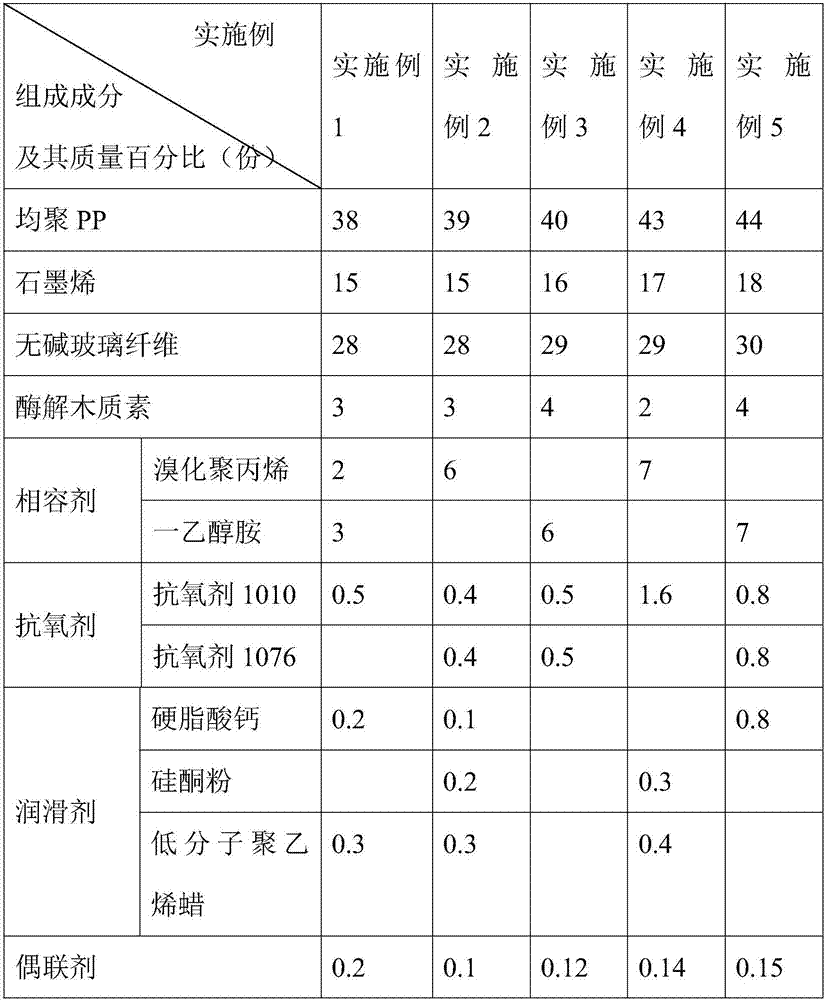

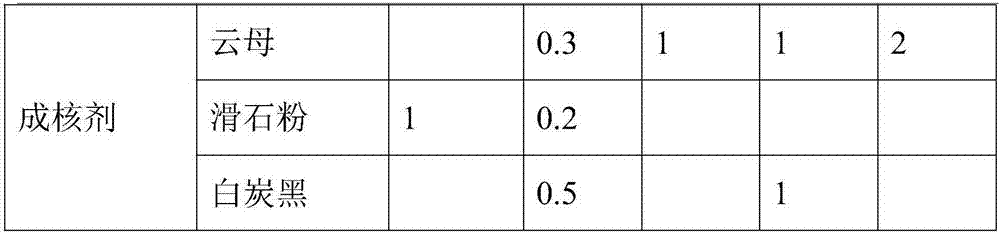

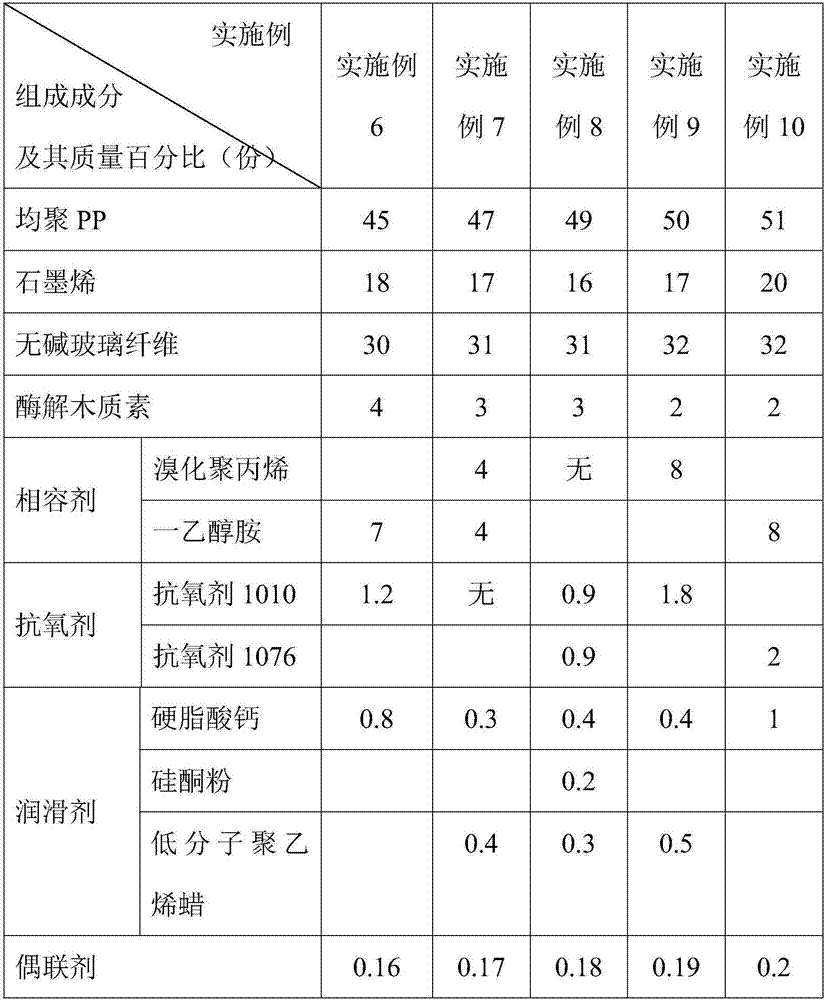

Examples

Embodiment 1

[0037] Take the component of high-strength and high-rigidity graphene-modified polypropylene material by the parts by weight described in embodiment 1 in table 1, wherein the molecular weight of homopolypropylene is 5000, and graphene is double-layer graphene, alkali-free The glass fiber has a length of 2.0 mm and a diameter of 12 μm;

[0038] Add other components except the alkali-free glass fiber into the mixer and mix for 4 minutes, and the speed of the mixer is 500rpm / min;

[0039] Pour the uniformly mixed material into a twin-screw extruder for extrusion and granulation. The main engine speed of the twin-screw extruder is 25HZ, the main feed is 15HZ, the side feed is 10HZ, the temperature is set at 235°C, and extrusion is granulated. At the same time, the alkali-free glass fiber is added from the side feeding port of the twin-screw machine by the weightless feeding method to obtain high-strength and high-rigidity graphene-modified polypropylene pellets.

Embodiment 2

[0041] Take the component of high-strength and high-rigidity graphene-modified polypropylene material by weight parts described in embodiment 2 in table 1, wherein the molecular weight of homopolypropylene is 5200, graphene is double-layer graphene, alkali-free The glass fiber has a length of 2.1 mm and a diameter of 12 μm;

[0042] Add other components except the alkali-free glass fiber into the mixer and mix for 4 minutes, and the speed of the mixer is 300rpm / min;

[0043] Pour the uniformly mixed material into a twin-screw extruder for extrusion and granulation. The main engine speed of the twin-screw extruder is 30HZ, the main feed is 17HZ, the side feed is 10HZ, the temperature is set at 240°C, and extrusion is granulated. At the same time, the alkali-free glass fiber is added from the side feeding port of the twin-screw machine by the weightless feeding method to obtain high-strength and high-rigidity graphene-modified polypropylene pellets.

Embodiment 3

[0045] Take the component of high-strength and high-rigidity graphene-modified polypropylene material by weight parts described in embodiment 3 in table 1, wherein the molecular weight of homopolypropylene is 4700, and graphene is double-layer graphene, alkali-free The glass fiber has a length of 1.8 mm and a diameter of 13 μm;

[0046] Add other components except alkali-free glass fiber into the mixer and mix for 3 minutes, and the speed of the mixer is 400rpm / min;

[0047] Pour the uniformly mixed material into a twin-screw extruder for extrusion and granulation. The main engine speed of the twin-screw extruder is 35HZ, the main feed is 18HZ, the side feed is 11HZ, the temperature is set at 235°C, and extrusion is granulated. At the same time, the alkali-free glass fiber is added from the side feeding port of the twin-screw machine by the weightless feeding method to obtain high-strength and high-rigidity graphene-modified polypropylene pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com