Modular slope greening method

A modular, slope technology, applied in the fields of botanical equipment and methods, excavation, construction, etc., can solve the problems of long construction period, affecting the safety of the surrounding environment, and large slope deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0030] As shown in the figure, the modular slope greening method includes the following steps:

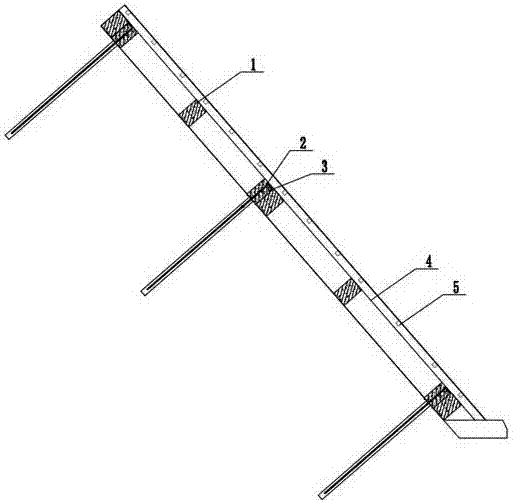

[0031] 1) Slope cleaning: remove weeds, branches, and construction waste on the slope, artificially remove and clean up unstable rock structures, and keep the original concrete slope protection 1 unchanged; if there is no slope support structure, Then complete the original concrete slope protection 1 of the slope according to the design specifications;

[0032] 2) Build a construction platform in accordance with the construction specifications to form an effective working surface;

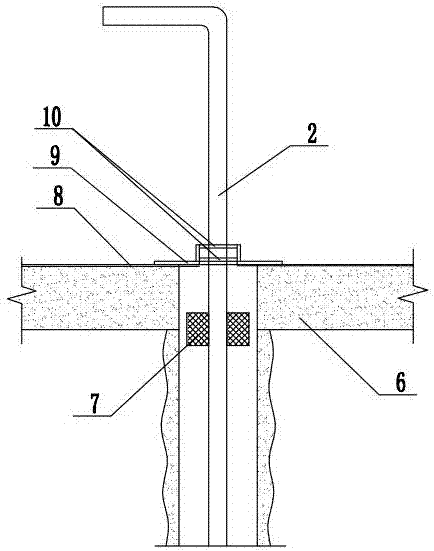

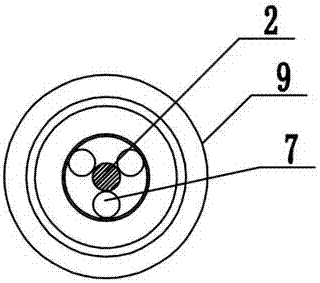

[0033] 3) In accordance with the technical specifications for bolt shotcrete support, carry out anchor bolt hole forming, anchor bolt production, grouting and anchor bolt;

[0034] 4) Set concrete pier 3 at the end of the anchor rod 2 for reinforcement, and rely on the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com