Method for measuring flow of emulsion through combination of conductivity sensor and electromagnetic flowmeter

A technology of conductance sensor and electromagnetic flowmeter, which is applied in the fields of measurement, fluid production, earthwork drilling, etc., can solve the problems of difficulty in reconstruction, and the measurement method of oil-in-water emulsion flow parameters has not yet been seen, and achieves high measurement resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

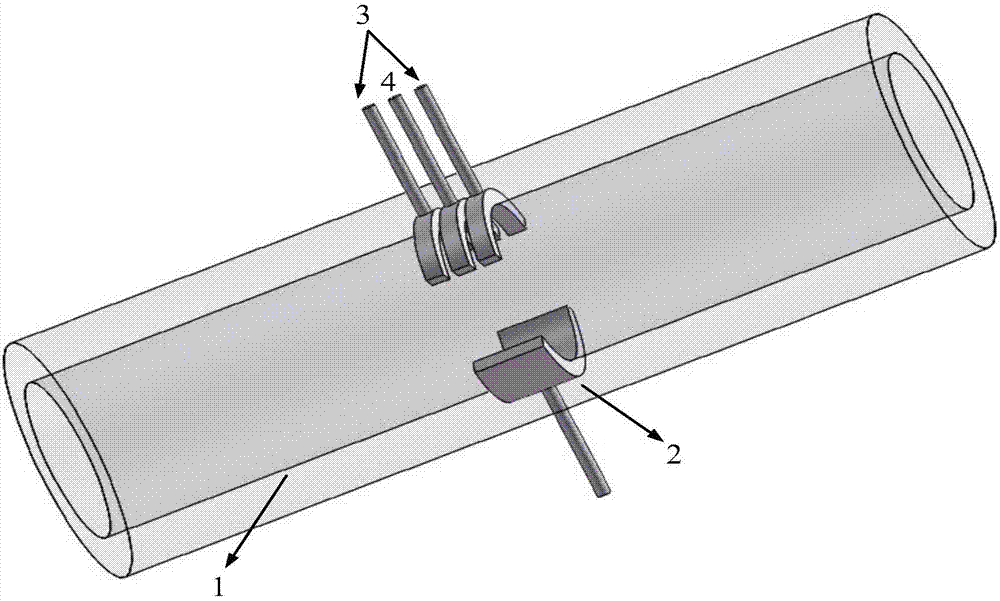

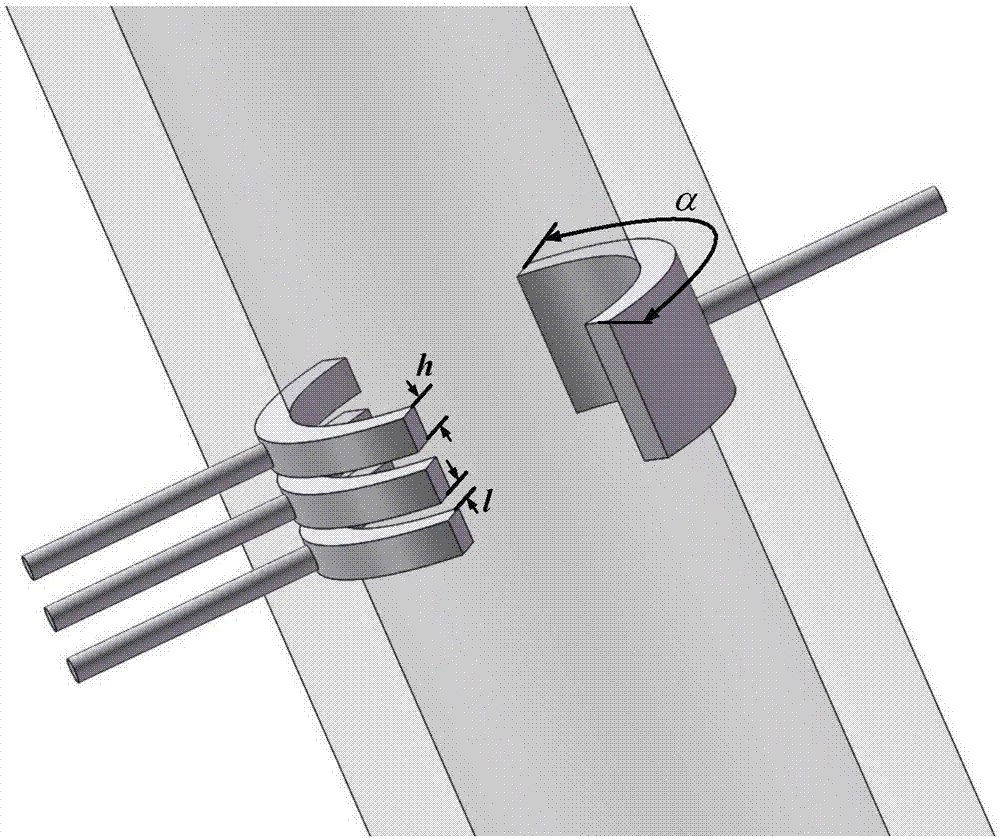

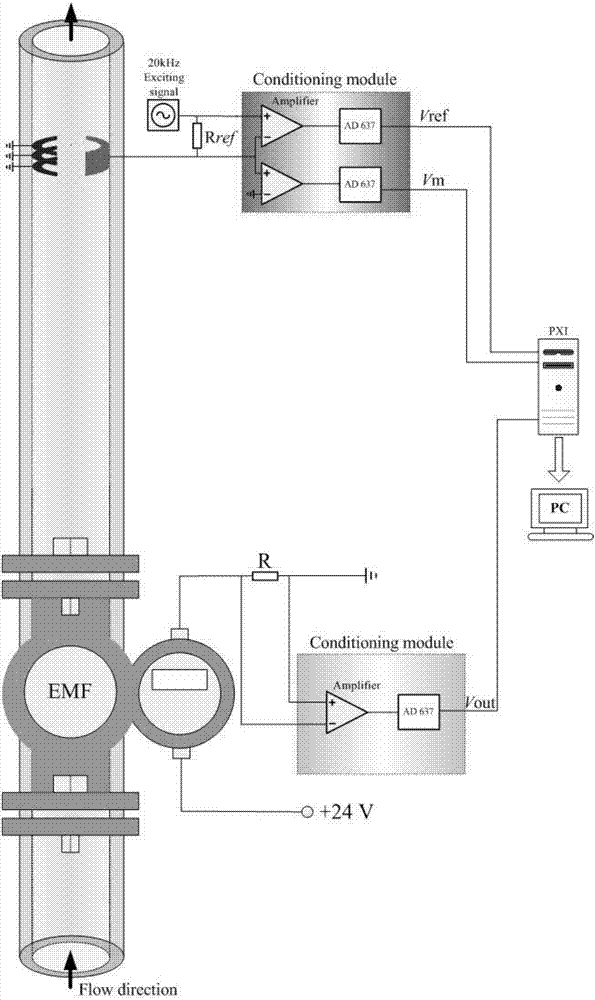

[0026] In order to realize the phase-separated flow measurement of oil-in-water emulsion under the action of surfactant, the present invention proposes a combined measurement method of a field-focused arc-shaped wall-to-wall conductivity sensor and an electromagnetic flowmeter. Among them, the field-focused arc-shaped wall-to-wall conductance sensor constructs an excitation electrode and a central measurement electrode that are spatially opposite to each other through the inner wall of the small-diameter measurement channel after current collection. Edge protection electrodes of the same size are placed at equal distances on both sides of the central measuring electrode. The same load is applied to the central measuring electrode and the edge protection electrode. According to the principle of electrical sensitivity, the electric field intensity at the central electrode is significantly enhanced, and at the same time, the edge effect of the electric field is effectively suppres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com