Apparatus and method for measuring noncontact Hopkinson pressure bar

A Hopkinson pressure bar, non-contact technology, applied in the direction of measuring devices, using one-time impact force to test material strength, instruments, etc., can solve the problems of limited measurement accuracy, influence, and inability to complete accurate measurement, so as to improve measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

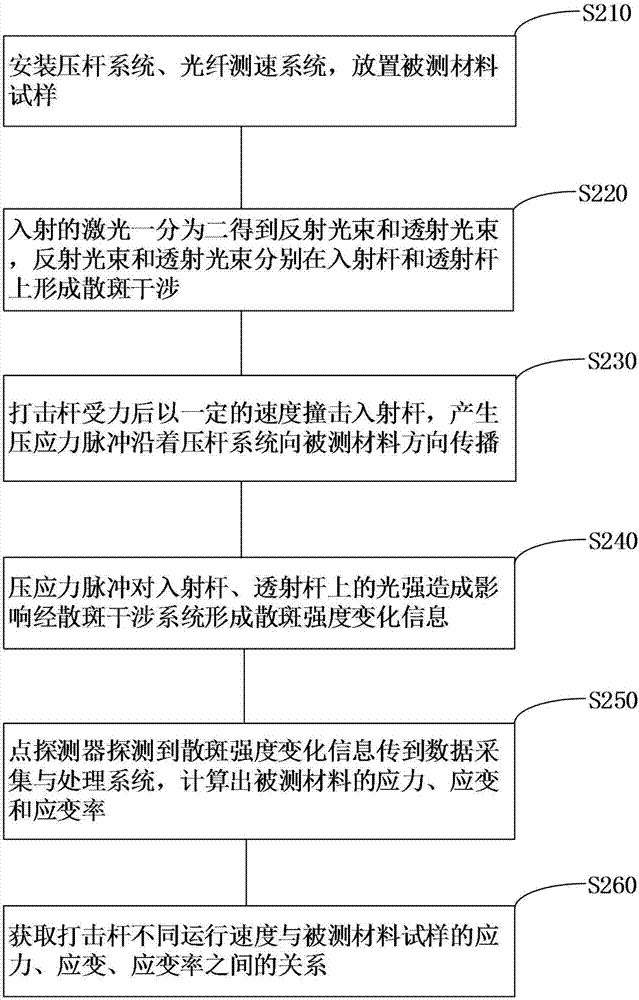

[0062] Speckle interferometry technology is developed under the background of the increasing development of laser technology. When the laser is irradiated on the surface of an object with diffuse reflection properties, the light reflected from the surface of the object will coherently superimpose in space, and interference will occur in the entire space. , forming randomly distributed bright and dark spots.

[0063] Speckle interferometry technology is divided into electronic speckle interferometry technology and time series speckle interferometry technology. Electron speckle interferometry can be used to measure out-of-plane and in-plane displacement components, strain, slope, curvature and vibration of objects with diffuse reflective surfaces. The time series speckle interferometry technology is to extend the range of electronic speckle interferometry to the whole process detection of the real variable field; it records the whole process of object movement, obtains a series ...

Embodiment 2

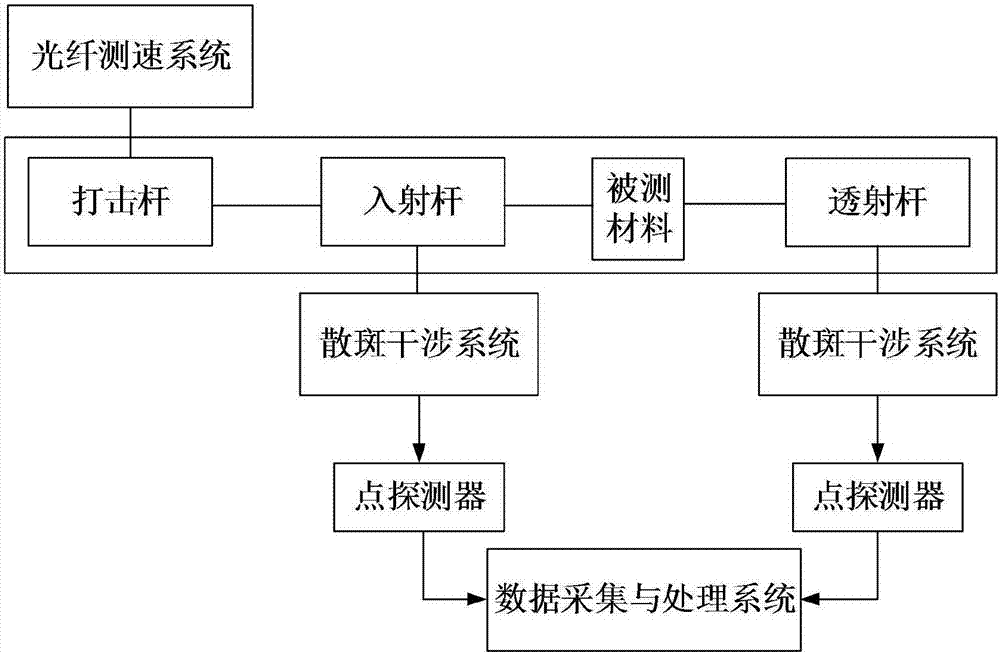

[0110] The embodiment of the present invention provides a non-contact Hopkinson bar measurement device, its specific structure diagram is as follows Figure 5 As shown; using this method to measure the dynamic mechanical properties of materials is mainly to improve the measurement accuracy of the Hopkinson pressure rod measurement method, so that the Hopkinson pressure rod device can complete the material under high strain when the diameter of the rod is less than 3 mm. Accurate measurement of dynamic mechanical properties at high rates.

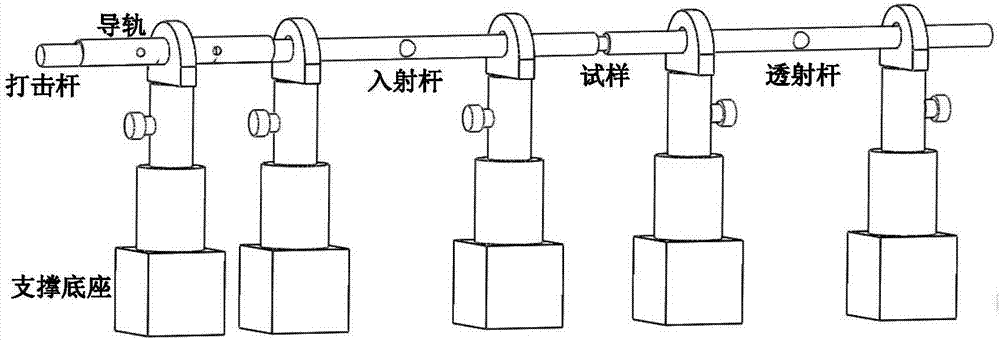

[0111] For the measurement of small-sized material samples, the device used in the embodiment of the present invention and the selection method of the tested material samples are as follows:

[0112] The diameter of the pressing rod is D=2mm, and the length mainly depends on the length of the striking rod, which is used to distinguish the incident wave from the reflected wave; if the length of the striking rod is L / D=10, then L / D>50 should b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com