Residual magnetism gradient distribution controlled NdFeB permanent-magnet material and preparation method thereof

A permanent magnet material and gradient distribution technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of invariable gradient, complex structure design, and poor adaptability to conditions, so as to reduce the complexity of design and make the preparation method simple Ease of operation and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] A method for preparing a NdFeB permanent magnet material with controllable remanence gradient distribution, comprising the following steps:

[0059] (1) Raw material preparation

[0060] Prepare permanent magnet material raw materials according to the following material composition ratio: The chemical composition of NdFeB permanent magnet material is expressed in mass percentage: Nd 28-30%, Ga 0.3-0.7%, Co 4-6%, B0.8-1.2 %, Al 0.18-0.28%, Cu 0.1-0.3%, M 0.06-0.1%, and the balance is Fe. Wherein, M is one or more of Dy, Ho and Tb.

[0061] In order to compensate the burning loss of rare earth Nd in the process of alloy smelting, add 1-2% more metal Nd to compensate in the process of batching.

[0062] (2) Melting and rapid quenching

[0063] The configured NdFeB raw materials are smelted in a vacuum electric arc furnace or an induction melting furnace to obtain corresponding alloy ingots; the smelted alloy ingots are roughly crushed and put into a vacuum quenching fur...

Embodiment 1

[0079] NdFeB permanent magnet material (block magnet) with remanence gradient distribution, the composition is 28% Nd, 0.5% Ga, 4% Co, 0.9% B, 0.18% Al, 0.25% by mass percentage % Cu, 0.08% Dy, and the rest is iron for batch smelting.

[0080] During the quick quenching process, the temperature is 1200°C, the injection pressure is 0.03Mpa, the quick quenching roll speed is 20m / s, and the particle size of the magnetic powder is 0.2-0.5mm.

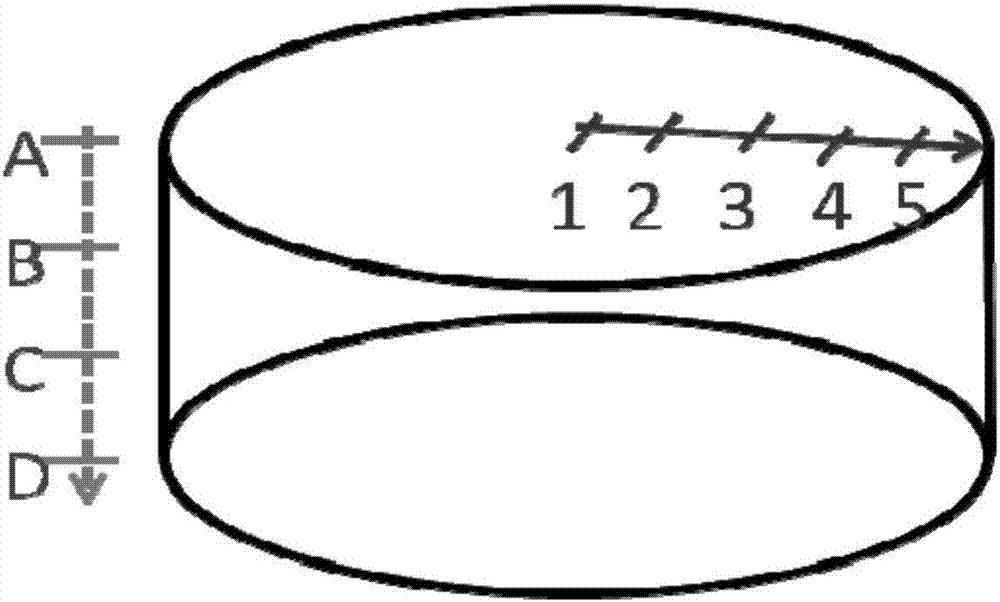

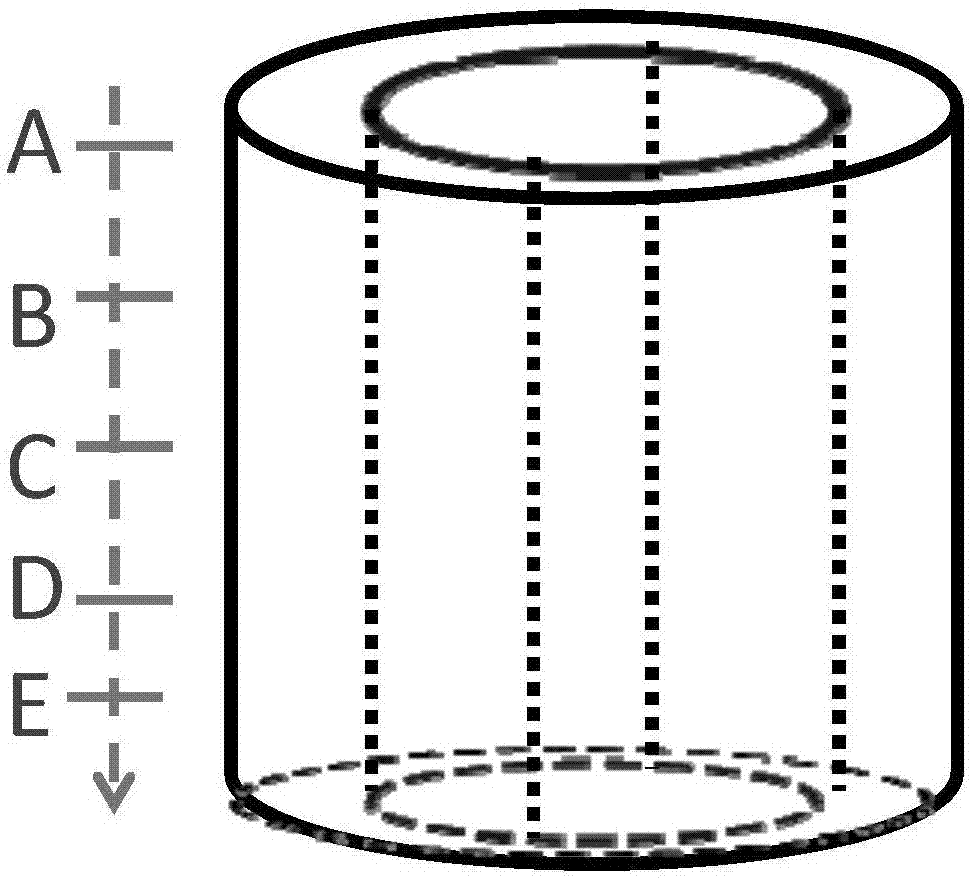

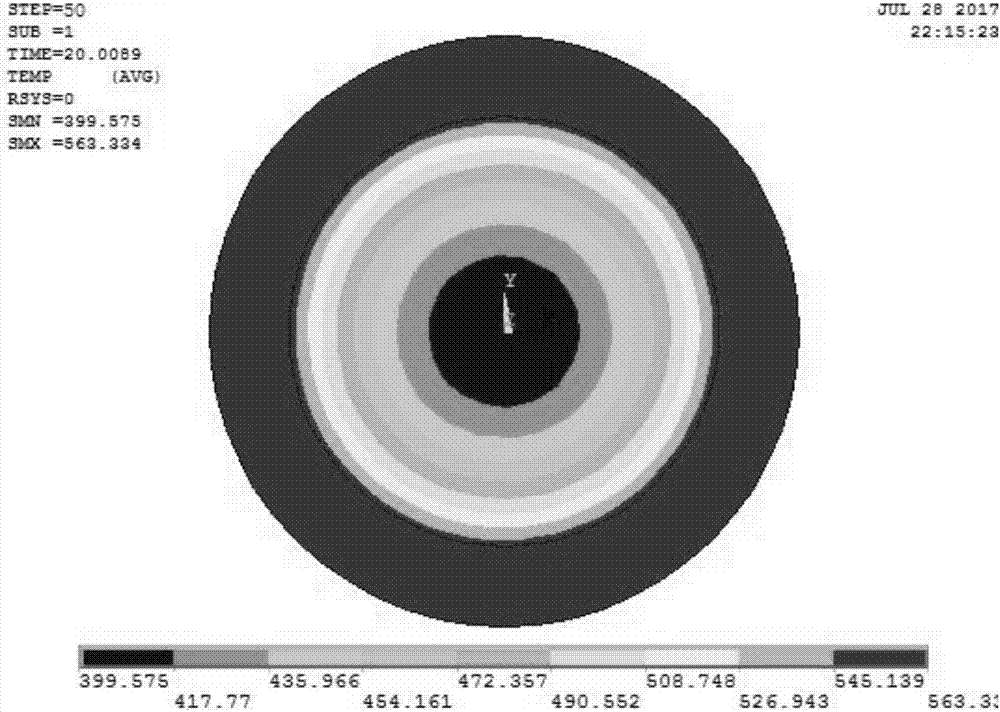

[0081] Gradient pressure and variable flow rate are used to carry out the hot-pressing thermo-rheological process. The first stage of hot-pressing is heat preservation for 60s, the second stage is heat preservation for 65s, and the pressure of the lower cylinder in the third stage is 6.8t; the thermorheological temperature is 850°C, and the movement speed of the upper and lower cylinders in the initial stage Both are 3mm / s, and the uniform movement time is 45s; in the second stage, the movement speed of the upper cylinder is 3mm / s, the movem...

Embodiment 2

[0084] NdFeB permanent magnet material (block magnet) with remanence gradient distribution, the composition is 29% Nd, 0.7% Ga, 5% Co, 1.0% B, 0.24% Al, 0.1% by mass percentage % Cu, 0.08% Tb, and the rest is iron for batch smelting.

[0085] During the quick quenching process, the temperature is 1230°C, the injection pressure is 0.04Mpa, the quick quenching roll speed is 30m / s, and the particle size of the magnetic powder is 0.1-0.4mm.

[0086] Gradient pressure and variable flow rate are used to carry out the hot-pressing thermo-rheological process. The first stage of hot-pressing is held for 65s, the second stage is held for 63s, and the pressure of the lower cylinder in the third stage is 7t; the thermorheological temperature is 890°C. In the initial stage, the motion speed of the upper and lower cylinders is 4mm / s, and the uniform motion time is 42s; in the second stage, the motion speed of the upper cylinder is 4mm / s, and the motion speed of the lower cylinder is 4.5mm / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com