Intermediate transformer and dry electromagnetic device of using same

A technology of transformer and accommodating cavity, which is applied in transformer/inductor core, transformer/inductor shell, transformer/inductor components, etc., can solve the problems of many loss materials, affect accuracy, easy to heat, etc., to save energy Silicon steel sheet and steel, the effect of improving insulation performance and improving magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the following examples.

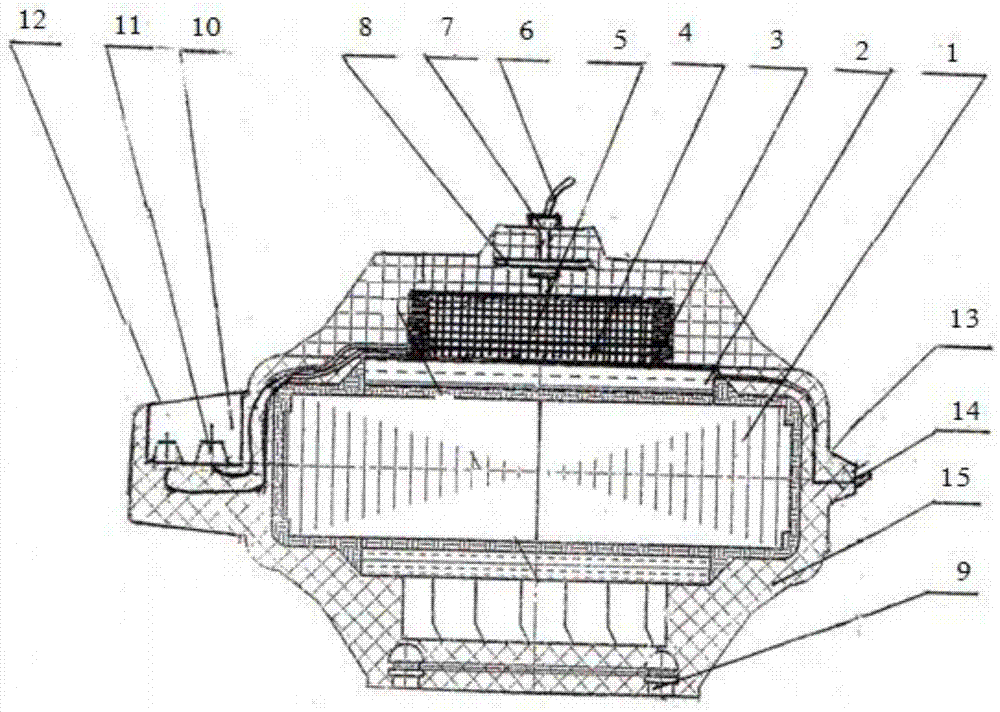

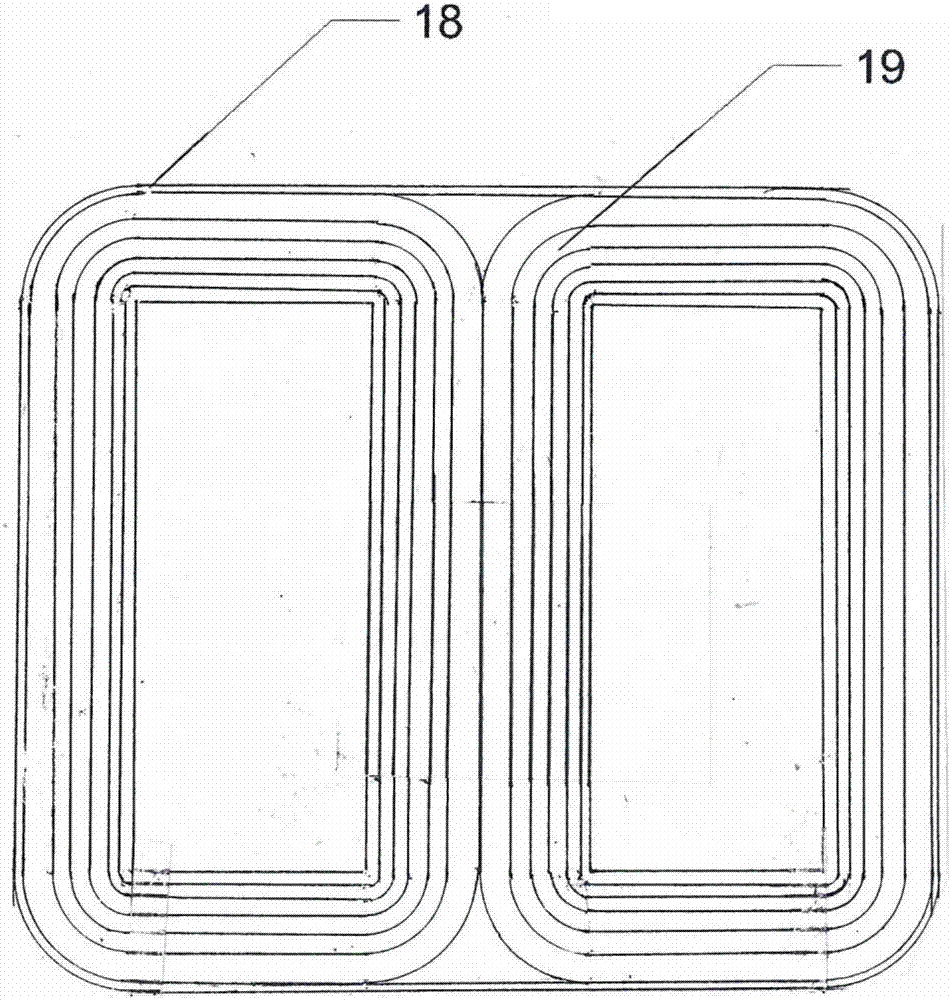

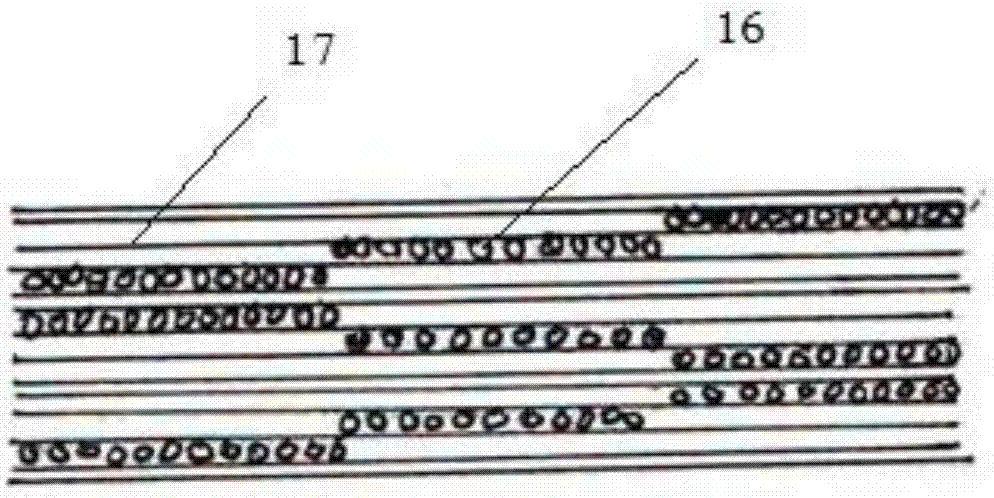

[0021] Such as figure 1 As shown, an intermediate transformer of the present invention includes a housing 15 made of insulating material. The housing 15 is provided with an accommodating cavity. The accommodating cavity is provided with an iron core 1 and a coil wound around the iron core 1, such as figure 2 As shown, the core 1 is wound into two stepped semi-cylindrical cores with multiple silicon steel strips 19 of different widths. The two stepped semi-cylindrical cores are combined into a "day" shape, and then a long silicon steel sheet 18 is used to wind the cores. As a whole of the gap, such a structure does not need to be punched, especially after heat treatment, it greatly improves the permeability, the magnetic circuit length is short, the leakage reactance is small, the leakage flux is less, the accuracy can reach 0.2 level or more, it is not easy to be saturated, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com