Cell culture medium

A culture medium, feed medium technology, applied in the field of cell culture and recombinant protein production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

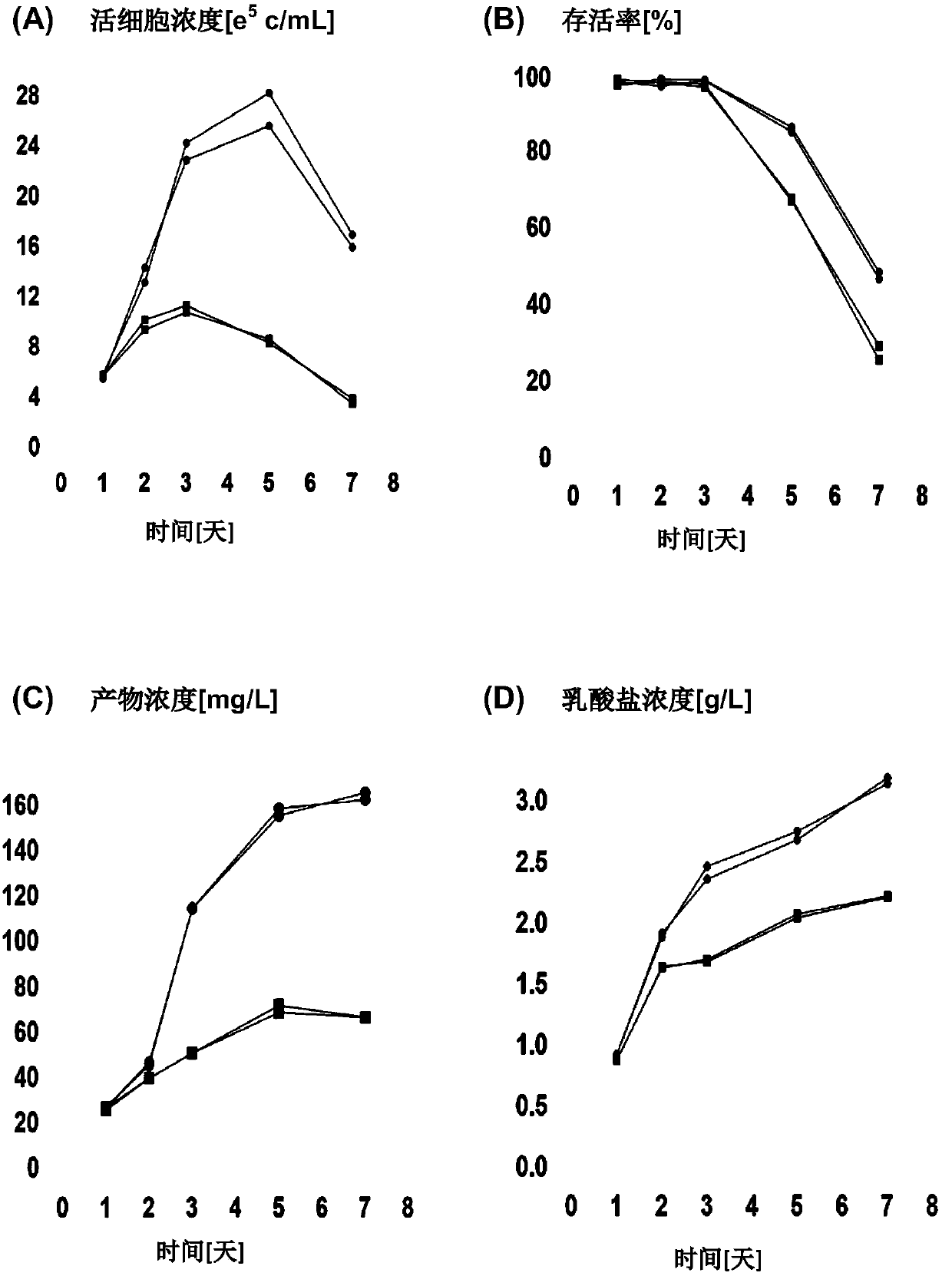

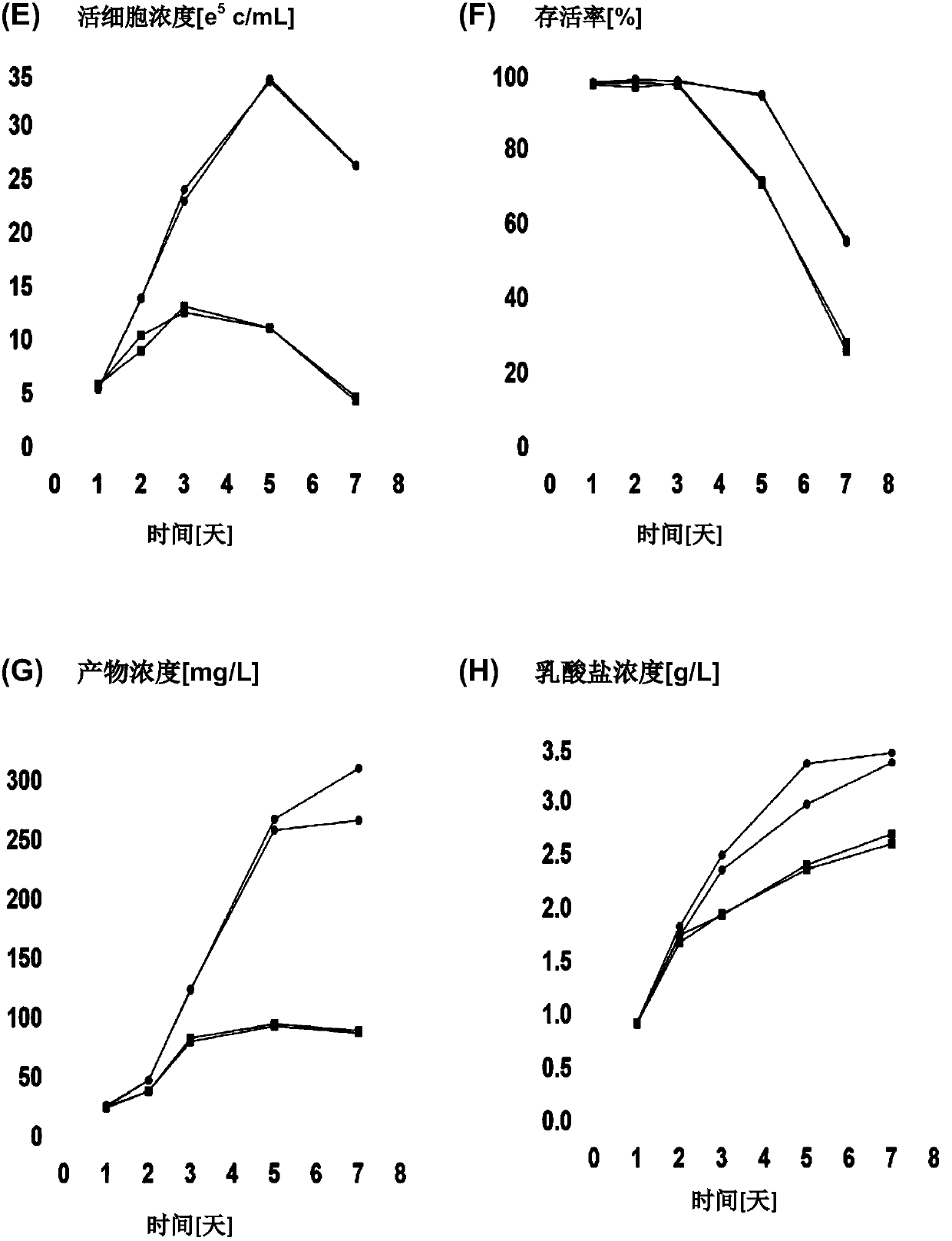

[0171] CHO2 (CHO-DG44) rituximab cells were cultured in RPMI-based basal medium, RPMI amino acid (AA) ratios versus optimal amino acid (AA) ratios with different total cumulative amino acid amounts. Medium 4 with RPMI AA ratios (Medium 4.0, 4.1, 4.2 and 4.3) and medium with optimized AA ratios ( The media compositions of media 5.0, 5.1 and 5.2) are shown in Table 1 and the corresponding amino acid ratios are shown in Table 2.

[0172] Small changes in total AA concentration are due to changes in molecular weight and minimal changes in the amino acid powder used. The purpose of this experiment was to demonstrate the effect of optimized amino acid ratios at different total cumulative amino acid levels. Experiments were performed in batch mode in duplicate (N=2).

[0173] Table 1: Composition of media 4.0, 4.1, 4.2 and 4.3 and media 5.0, 5.1 and 5.2

[0174]

[0175] *Gln, Ile and Cys were added with stock solution

[0176] **Gln and Ile were added with original solution ...

Embodiment 2

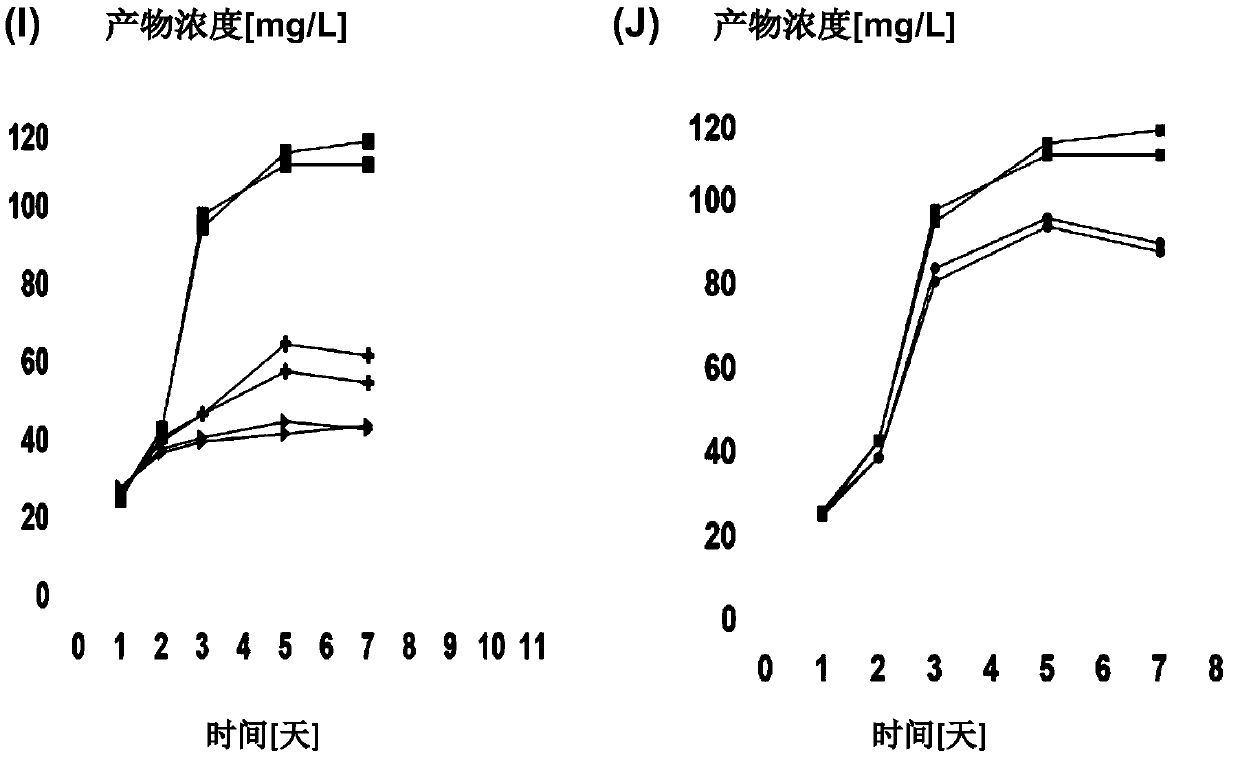

[0191] Based on the optimized amino acid ratios of basal medium 5 (RPMI-based), several amino acids varied + / - 20% and + / - 40% in their molar concentrations as single component methods (calculated based on optimized AA ratios mole percent). This performance was then compared to a control culture grown in medium 5.3 (same as medium 5.0, but with all amino acids added individually as stocks). All essential amino acids are provided in concentrated stock solutions to engineer different media compositions. Thus, the media had comparable total cumulative amino acid amounts of approximately 43-44 mM, but different amino acid ratios. In one experiment, +20% and -20% changes in single amino acid concentrations (L-arginine, L-asparagine, L-aspartate, L-histamine) relative to control medium 5.3 were tested. acid, L-leucine, L-lysine, L-methionine, L-phenylalanine, L-proline, L-serine, L-threonine, L-tryptophan, Single component approach for L-tyrosine, L-valine). For single amino aci...

Embodiment 3

[0204] Based on the optimized amino acid ratios and the amino acids identified in Example 2 in basal medium 5 (RPMI-based), the additional amino acids varied in their molar concentrations in different medium backgrounds due to the single component approach - 40%. This medium containing optimized AA ratios was further optimized for serum-free recombinant protein production and was chemically defined and superior to the modified RPMI medium used in previous experiments. In this experiment, single amino acids were reduced in batch mode to demonstrate the effect of optimal amino acid ratios on pH, dissolved oxygen (DO) and temperature in basal media under controlled bioreactor conditions.

[0205] Based on the optimized amino acid ratio in basal medium 6.2, the single amino acid L-lysine, L-methionine, L-proline, L-tryptophan or L-tyrosine in its molar concentration A 40% reduction, or a 20% or 40% reduction in both L-tyrosine and L-lysine. The resulting performance was compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com