A keyhole repair tool and repair method after friction stir welding

A technology of friction stir welding and repair method, which is applied to manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve problems such as high residual stress, poor connection effect, and many pores, and achieves high connection strength, good repair surface quality, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

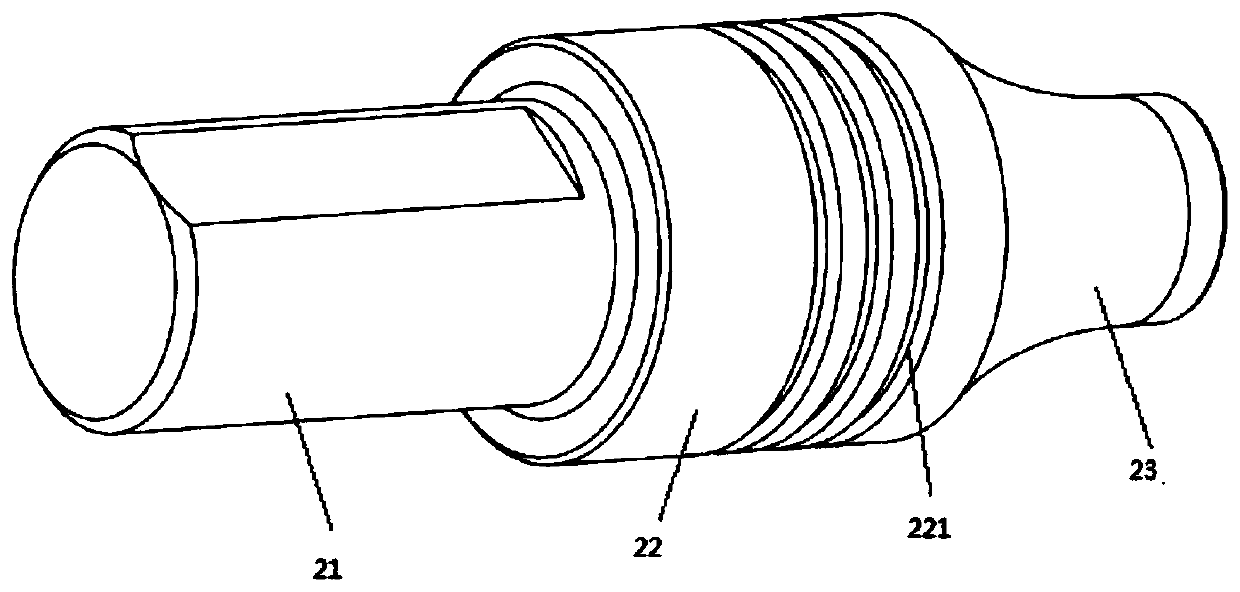

[0051] The traditional heat transfer method or forced air cooling method relying on single-phase fluid to form convection is far from meeting the heat dissipation requirements of high power and high heat flux density. The new heat dissipation method requires the radiator to be flexible, reliable, compact, high heat dissipation efficiency and The latest design and molding method of the radiator that can meet the above heat dissipation requirements is the cold plate structure. That is: the cold plate is composed of a base plate and a cover plate. First, a large-thickness aluminum plate (or copper plate) is machine-milled with runner grooves to form the base plate, and then the cover plate is embedded on the base plate, so that the two are closely bonded. The advanced friction stir welding process is used to weld all around the cover plate to form a sealed cavity between the cover plate and the base plate. At the same time, imports and exports are added at both ends of the cold p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com