Powder particle size distribution control device and method of disc mill system

A particle size distribution and control device technology, applied in grain processing and other directions, can solve the problems of sampling time lag, waste, and limited accuracy of grinding disc gap control, and achieve the effect of improving control accuracy and ensuring real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

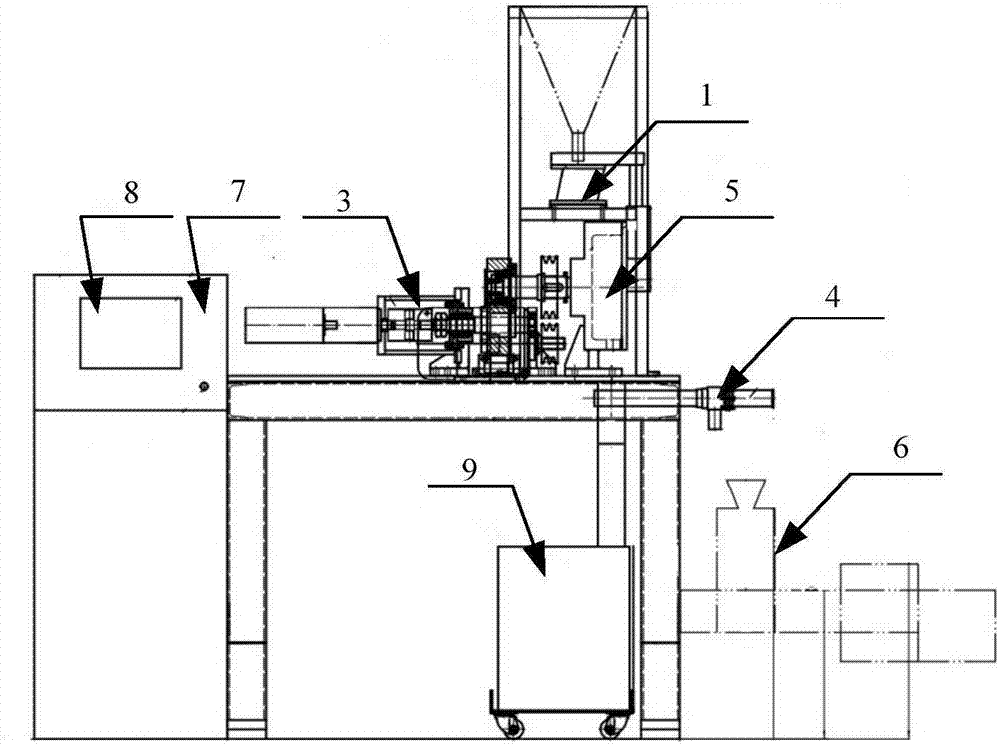

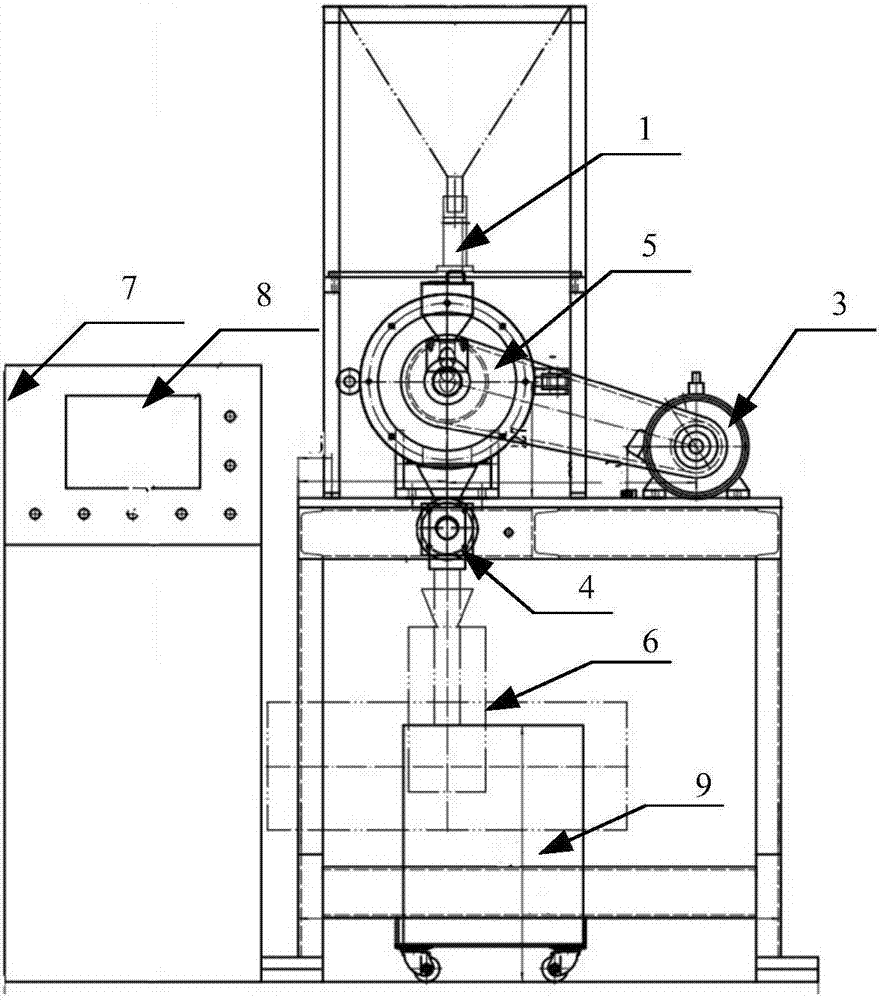

[0045] This embodiment provides a Figure 1~2 The powder particle size distribution control device of a disc grinding system shown includes:

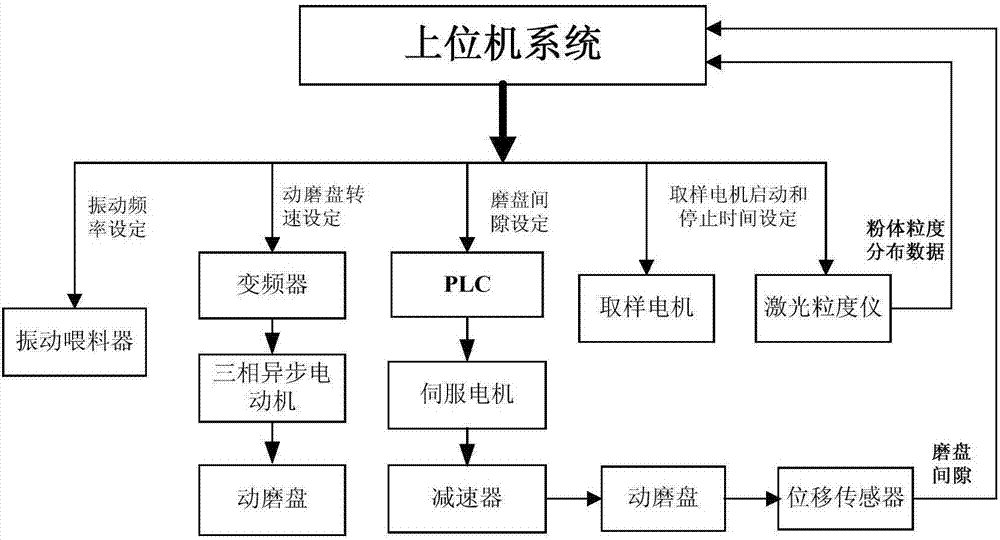

[0046] Feeding device 1: Select a vibrating feeder and connect it to the upper computer system, control the feeding amount according to the vibration frequency of the vibrating feeder, set the vibration frequency of the vibrating feeder, and realize the quantitative feeding of the disc grinding system. Its control process is as follows Figure 5 As shown, the vibration frequency of the vibrating feeder is set in the upper computer system, and the feeding amount is measured in real time during the vibration process of the vibrating feeder. When the required feeding amount is reached, the material enters the grinding area.

[0047] Rotating disc speed adjustment device 2: including frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com