High Efficiency Water Purification Filter

A water purification filter, high-efficiency technology, applied in the field of water purification filter, can solve problems such as chronic diseases or cancer, water quality safety concerns and worries, and difficult to detect, and achieve good adsorption performance, excellent antibacterial effect, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

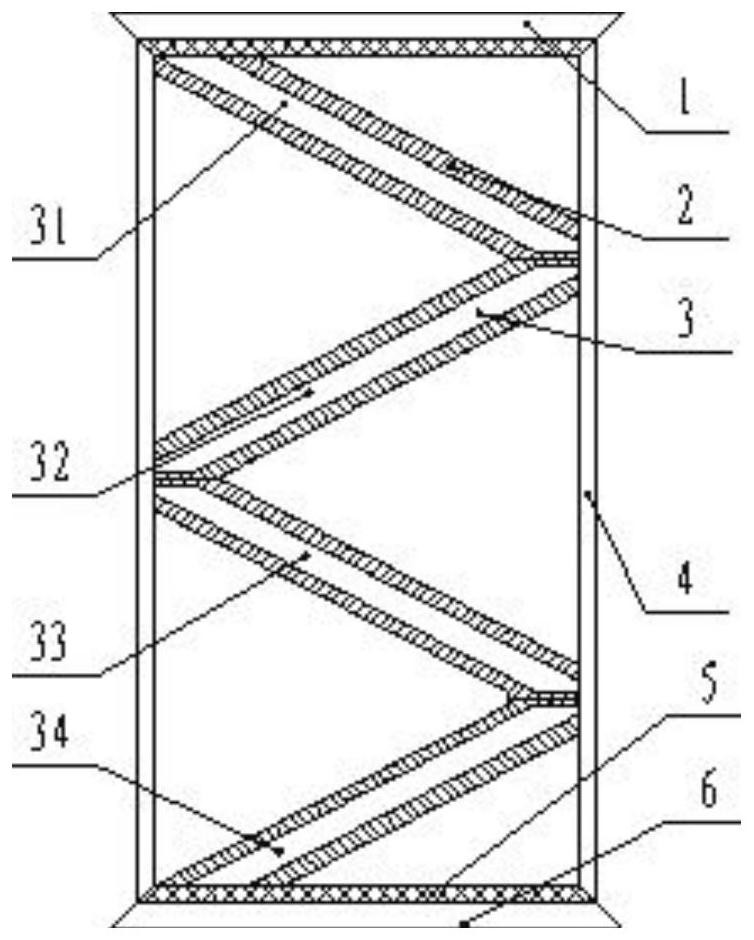

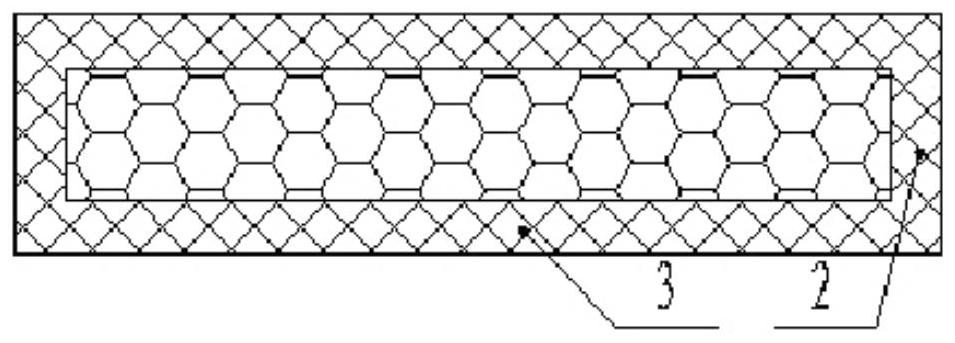

[0052] Please refer to figure 1 In an embodiment of the present invention, a high-efficiency water purification filter element includes: a water inlet 1, a first filter screen 5, a second filter screen 2, a filter material 3, a filter cartridge 4, and a water outlet 6;

[0053] The first filter screen 1 is horizontally and fixedly installed on the upper and lower ports of the filter cartridge 4, the inside of the second filter screen 2 is hollow, and a plurality of the second filter screens 2 are fixedly installed in a wave-shaped connection Inside the filter cartridge 4, there is an angle of 30° between the first filter screen 5 and the second filter screen 2; the water inlet 1 is located at the upper port of the filter cartridge 4, and is fixedly installed on the The surface of the first filter screen 5, the water outlet 1 is located at the lower port of the filter cartridge 4, and is fixedly installed on the surface of the first filter screen 5, the water inlet 1 and the wa...

Embodiment 2

[0067] Substantially the same as Example 1, the only difference is that the preparation method of the silver-loaded activated carbon comprises the following steps:

[0068] (1) Wash the activated carbon with distilled water until the washing solution is clear and colorless, and dry it in a drying oven at 120°C to constant weight to obtain dry activated carbon;

[0069] (2) Take 10 g of dry activated carbon and soak it in 250 ml of acid solution, soak it at 45 ° C for 3 hours, filter it with a 300 mesh filter cloth, dry the solid in a drying oven at 70 ° C for 6 hours, wash it with distilled water until the pH of the filtrate is neutral, Then dry in a drying oven at 120°C for 3 hours to obtain acid-modified activated carbon;

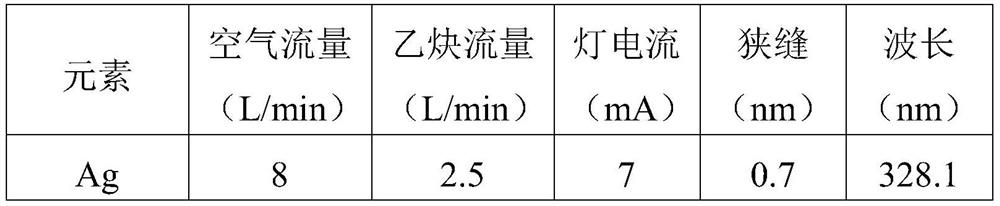

[0070] (3) Immerse the acid-modified activated carbon in 400ml of silver nitrate aqueous solution with a mass concentration of 5g / L, soak it at 25°C for 5 hours, then soak it at 120°C for 1 hour, and filter it with a 300-mesh filter cloth. Dried in dryin...

Embodiment 3

[0075] Substantially the same as Example 2, the only difference is that the preparation method of the silver-loaded activated carbon comprises the following steps:

[0076] (1) Wash the activated carbon with distilled water until the washing solution is clear and colorless, and dry it in a drying oven at 120°C to constant weight to obtain dry activated carbon;

[0077] (2) Take 10 g of dry activated carbon and soak it in 250 ml of acid solution, soak it at 45 ° C for 3 hours, filter it with a 300 mesh filter cloth, dry the solid in a drying oven at 70 ° C for 6 hours, wash it with distilled water until the pH of the filtrate is neutral, Then dry in a drying oven at 120°C for 3 hours to obtain acid-modified activated carbon;

[0078] (3) acid-modified activated carbon is soaked in 400ml mass concentration and is the silver nitrate aqueous solution of 5g / L, soaks 6 hours at 25 ℃, filters with 300 order filter cloths, and solid is dried 10 hours in the drying box of 50 ℃, obtains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com