Aerogel plastic film and preparation method thereof

A plastic film and aerogel technology, applied in the field of aerogel plastic film and its preparation, can solve the problems of complex process, high technical and capital requirements, difficulty in large-scale production, etc. The effect of omitting chemical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

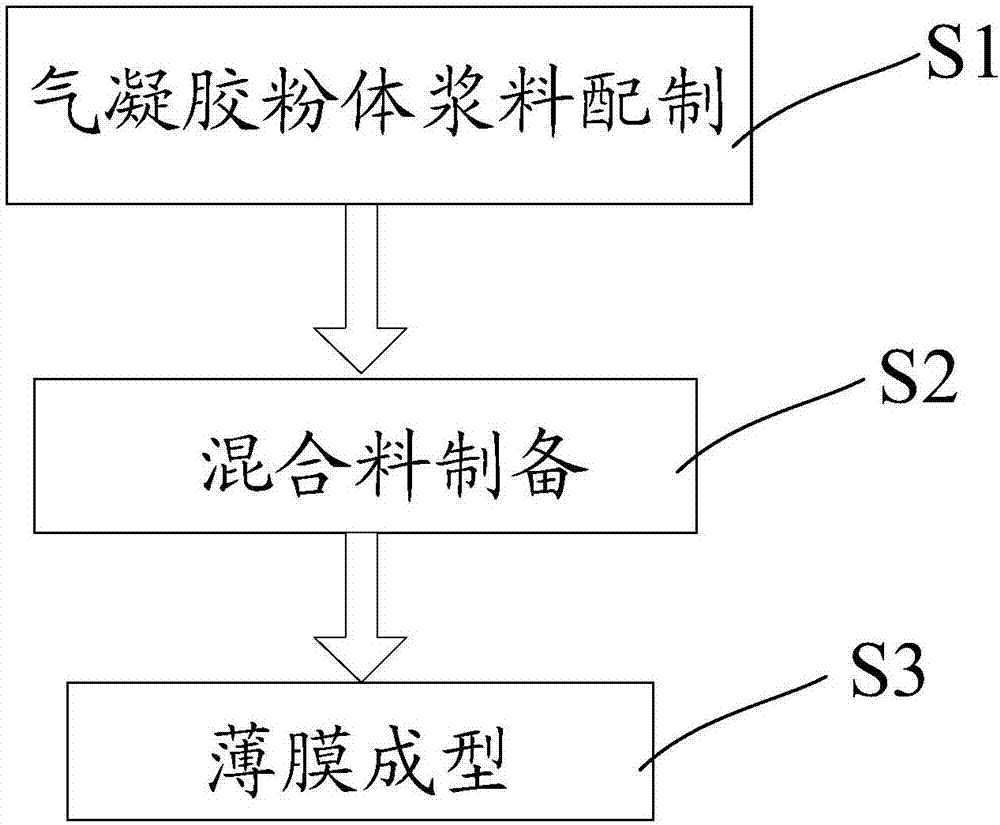

[0023] Such as figure 1 Shown, a kind of preparation method of airgel plastic film, it comprises the steps:

[0024] S1. Preparation of airgel powder slurry: fully mix airgel powder, interface agent, functional additive and water to obtain airgel powder slurry;

[0025] S2. Mixture preparation: put the airgel powder slurry and the resin material into the mixing equipment and mix evenly to obtain the mixture;

[0026] S3. Film forming: the mixture is made into a film through a forming process, which is the airgel plastic film.

Embodiment 1

[0028] An airgel plastic film, which is prepared by the following method:

[0029] S1. Preparation of airgel powder slurry: fully mix 50g of airgel powder with a particle size of 5-20μm, 10g of silane coupling agent, 10g of functional additive zinc oxide powder and 930g of ethanol to obtain airgel Powder slurry;

[0030] S2. Mixture preparation: 1000g of airgel powder slurry, 500g of polyacrylic resin powder and 500g of water-based polyurethane resin are put into a tank mixer and mixed evenly to obtain a mixture;

[0031] S3. Forming the film: spraying the mixture onto the hard and smooth surface of the template, drying to form a film, and obtaining the airgel plastic film. Its thickness is about 0.1-0.5mm, and the content of airgel powder in it is about 5wt%.

[0032] According to the performance test, the thermal conductivity of the above-mentioned airgel plastic film at room temperature is about 0.04W / (m·k).

Embodiment 2

[0034] An airgel plastic film, which is prepared by the following method:

[0035] S1. Preparation of airgel powder slurry: fully mix 150g of airgel powder with a particle size of 20-40μm, 20g of silane coupling agent, 5g of functional additive zinc oxide powder and 875g of ethanol to obtain airgel Powder slurry;

[0036] S2. Mixture preparation: put 1000g of airgel powder slurry and 1500g of polyvinyl alcohol resin powder into a trough mixer and mix evenly to obtain a mixture;

[0037] S3. Forming the film: roll coating the mixed material on the hard and smooth surface of the template, and drying it to form a film to obtain the airgel plastic film. Its thickness is about 1-2mm, and the content of airgel powder in it is about 10wt%.

[0038] According to the performance test, the normal temperature thermal conductivity of the above-mentioned airgel plastic film is about 0.035W / (m·k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com