A multifunctional engine circuit protection agent

A line protection, engine technology, applied in the direction of circuit, paint containing biocide, coating, etc., can solve the problems of poor weather resistance, effect effect, acid and alkali resistance, etc., to keep the engine room clean, prevent leakage, and easy to wipe Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

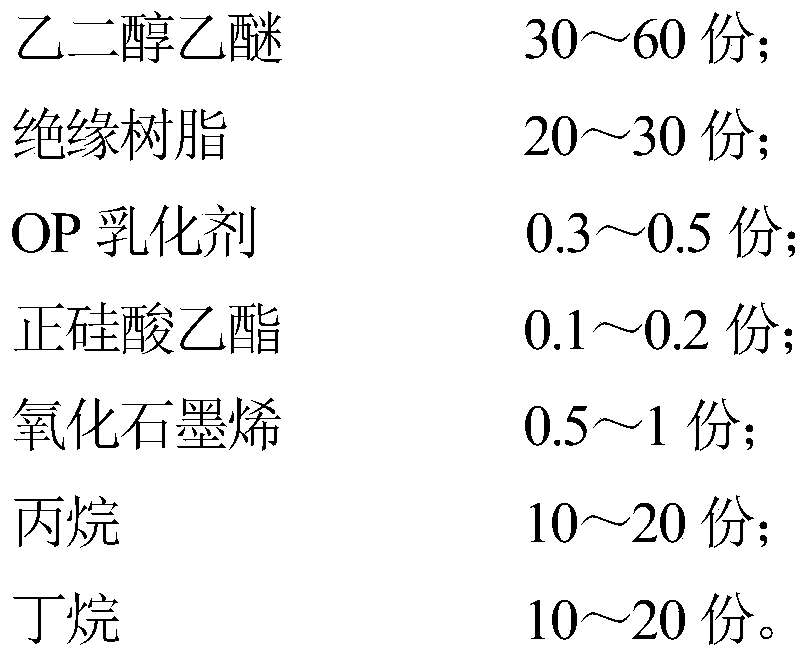

[0023] In this embodiment, the multifunctional engine circuit protection agent is uniformly prepared by mixing the following materials in parts by weight:

[0024]

Embodiment 2

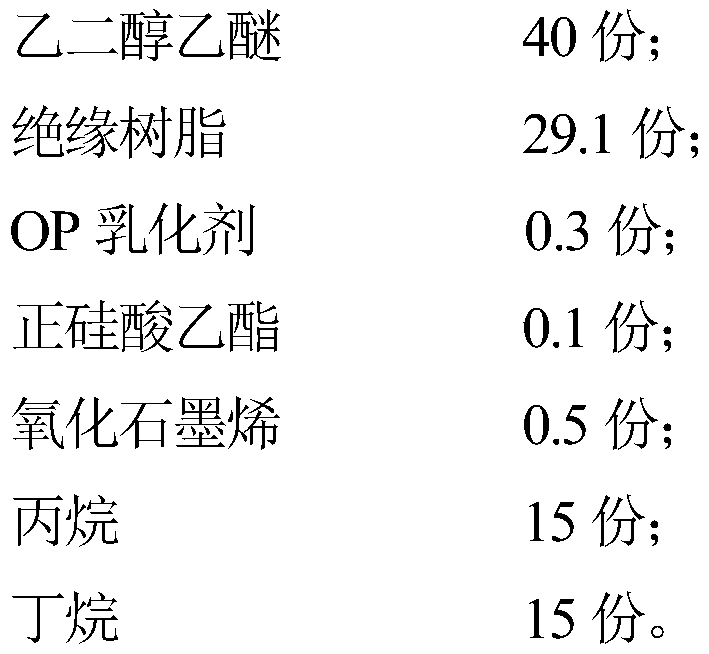

[0026] In this embodiment, the multifunctional engine circuit protection agent is uniformly prepared by mixing the following materials in parts by weight:

[0027]

Embodiment 3

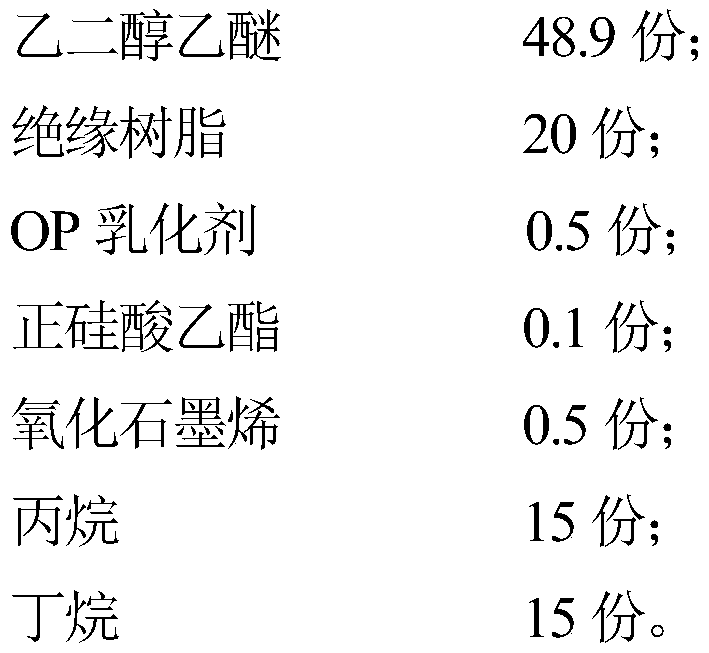

[0029] In this embodiment, the multifunctional engine circuit protection agent is uniformly prepared by mixing the following materials in parts by weight:

[0030]

[0031] In the embodiment 1-3, the specific preparation method of the multifunctional engine circuit protection agent is: uniformly mix ethylene glycol ether, insulating resin, OP emulsifier, tetraethyl orthosilicate, graphene oxide at normal temperature, pour into metal The finished product of the present invention can be obtained by filling the aerosol can with propane and butane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com