Reflective heat insulation coating and preparation method thereof

A technology of reflective thermal insulation coating and components, applied in the field of coatings, can solve the problems of single color, low solar reflectance ratio of reflective thermal insulation coating, general reflective thermal insulation effect, etc. Effects that meet the needs of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below.

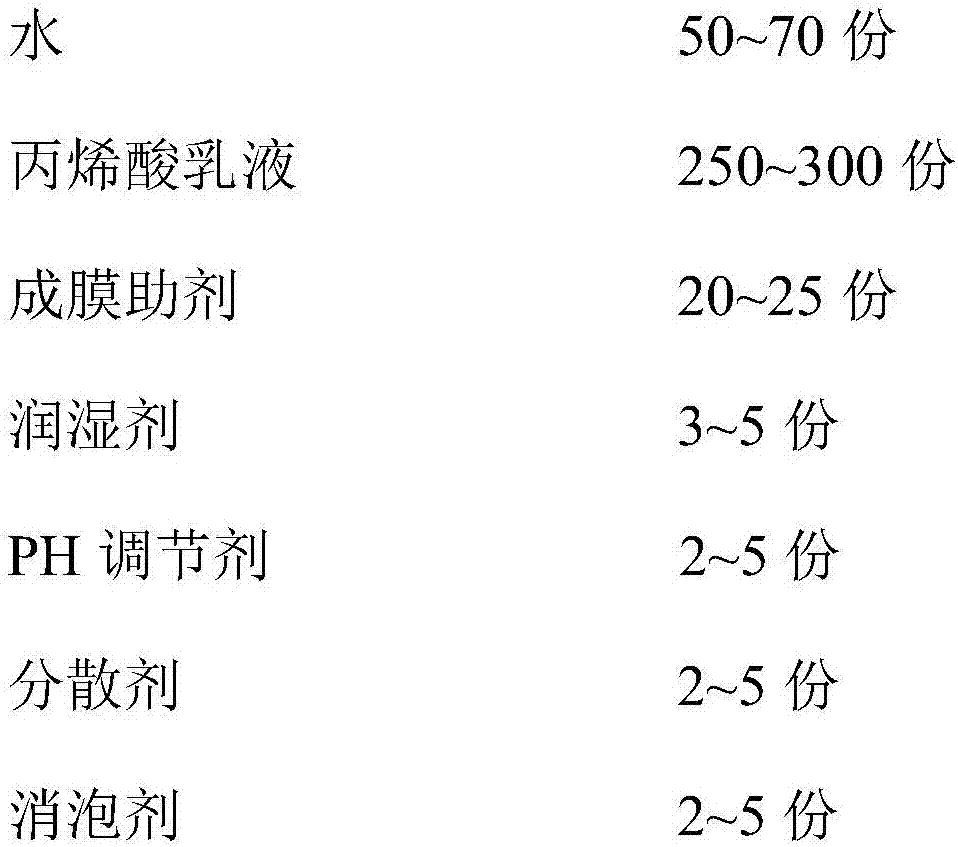

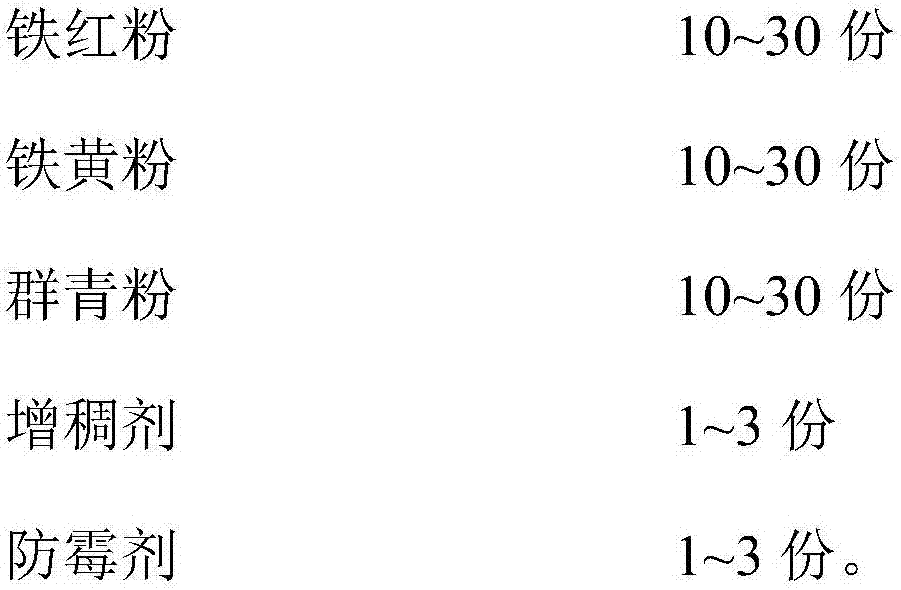

[0011] A reflective heat-insulating paint, comprising the following components and the weight ratio of each component is:

[0012]

[0013]

[0014] A method for preparing a reflective heat-insulating coating, comprising the following steps:

[0015] First mix water, film-forming aids, wetting agents, PH regulators, dispersants, and defoamers according to the ratio, and stir until uniform; add iron red powder, iron yellow powder and ultramarine powder into the above uniform solution according to the ratio, and use a mixer Stir at a high speed of 3000r / min~5000r / min for 20min~30min to obtain a dispersion system; adjust the rotor speed of the mixer to 800r / min~1200r / min, add acrylic emulsion to the above dispersion system, and stir for 15min~ 20min; adjust the rotor speed of the mixer to 250r / min-400r / min, add thickener and anti-fungal agent, and continue stirring for 10min-15min to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com