High-elasticity electrical-heating fiber, and its preparation method and application

An electric heating, high elasticity technology, applied in textiles and papermaking, coatings, yarns, etc., can solve problems such as no method developed, affecting air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

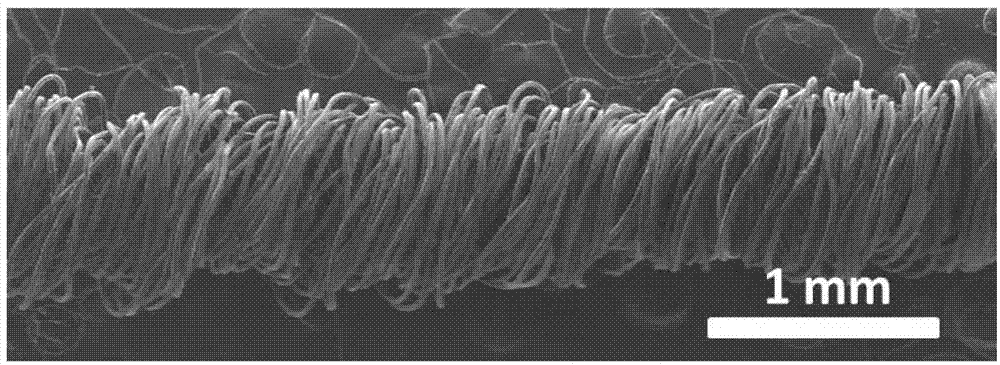

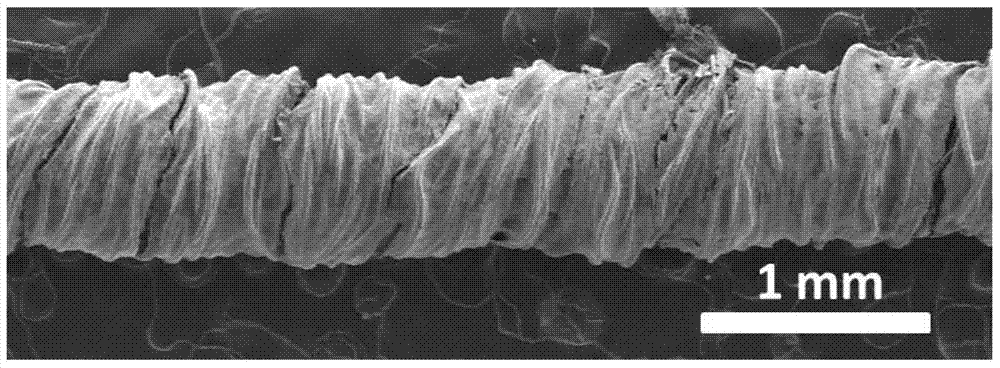

[0069] The S-shaped helical polyester fiber (such as figure 1 As shown, the helix diameter is 700um, and the fiber diameter is 20um) in the nano-silver colloid (diameter: 20-80nm, concentration: 0.1mg / mL, solvent: water) dispersion liquid dip coating 5 times, then carry out annealing treatment (100 °C, 0.5h), then infiltrated and coated in liquid PDMS, and finally cured (80°C, 3h), to obtain high-elastic electric heating fibers. The resistance per unit length measured by a multimeter is 2Ω / cm.

Embodiment 2

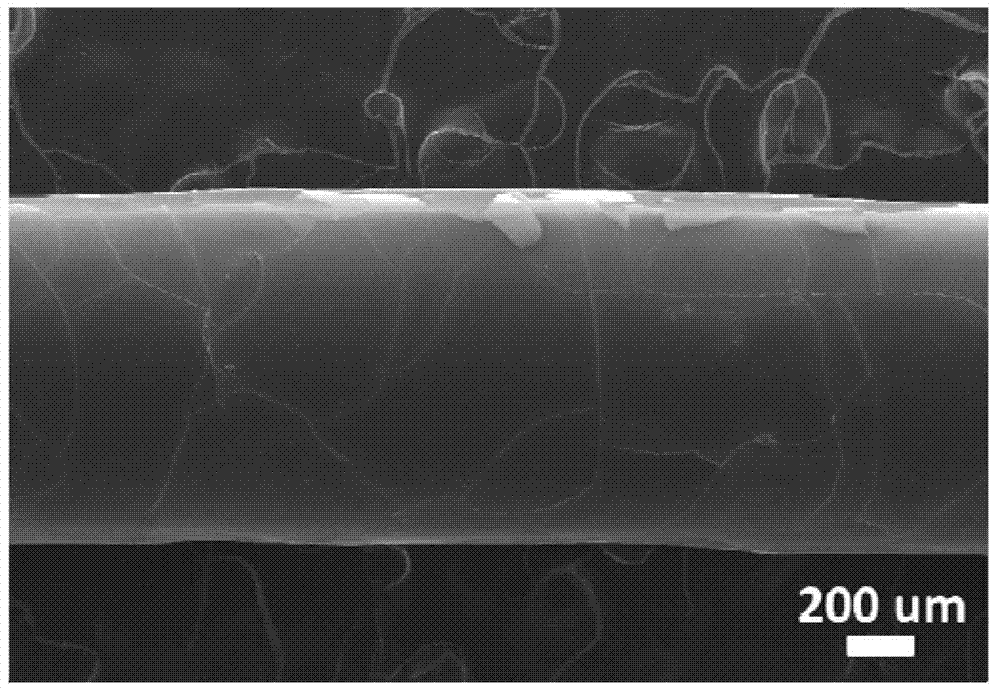

[0071] The S-shaped helical polyester fiber (such as figure 1 Shown) on nano-silver sheet (sheet diameter: ~0.5um, BET: 0.80-1.45m 2 / g) Dip coating in water solvent dispersion for 5 times, then annealing treatment (120°C, 1h), then permeate and coat in liquid PDMS, and finally cure (100°C, 2h) to obtain a highly elastic electrode Heating fibers. Its resistance per unit length is 3Ω / cm. Its SEM picture is as follows image 3 As shown, it can be seen that the high-elastic electric heating fiber is linear with uniform diameter as a whole.

Embodiment 3

[0073] The S-shaped helical polyester fiber (such as figure 1 Shown) Dip coating in silver nanowire ethanol dispersion (5mg / mL) for 5 times, then conduct hydrogen plasma treatment (100Pa, 100W, 10min), and then infiltrate and coat in liquid silicone rubber Ecoflex 00-30 Covering, and finally curing (100°C, 0.5h), to obtain high elastic electric heating fibers. Its resistance per unit length is 2.5Ω / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance per length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com