Construction technology of subsided toilet

A construction technology and bathroom technology, applied in the direction of floors, insulation layers, buildings, etc., can solve the problems of uneven stone laying, stress variation, stone cracking, etc., to improve living comfort, good compression resistance and structural strength , good water storage and drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

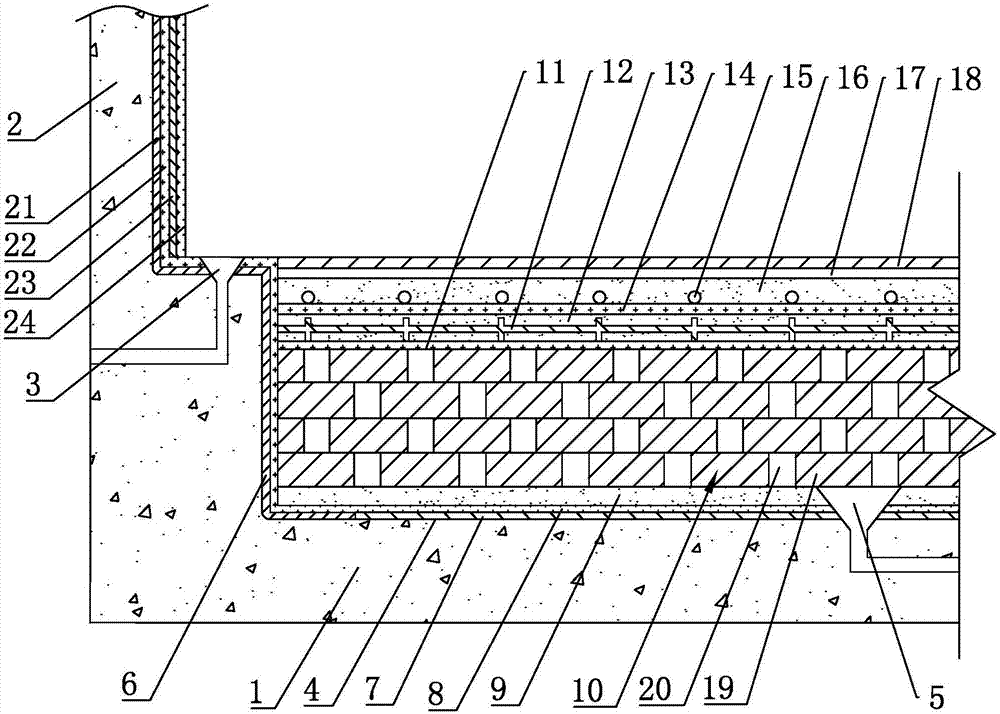

[0041] Such as figure 1 As shown, a sunken toilet includes a ground 1 and a wall 2. A surface floor drain 3 is arranged in the ground 1, and the upper surface of the surface floor drain 3 and the ground 1 are located on the same plane. The ground 1 is sunken to form a sinking tank 4 . A hidden floor drain 5 is arranged in the ground 1, and the hidden floor drain 5 is located in the sinking tank 4.

[0042] Such as figure 1 As shown, the bottom surface of the sinking tank 4 is sequentially provided with a second waterproof cement slurry layer 6, waterproof mortar leveling 7, first waterproof coating 8, waterproof mortar protective layer 9, brick floor cage 10, cement board 11, Steel bar support frame 12, first fine stone concrete layer 13, floor heating insulation board 14, floor heating pipe 15, second fine stone concrete layer 16, adhesive layer 17 and surface layer 18. The upper end surface of the surface layer 18 is located on the same plane as the ground 1 .

[0043] ...

Embodiment 2

[0050] Embodiment two is the construction method of embodiment one, comprises the following steps:

[0051] 1. The floor 1 of the toilet is sunken to form a sink 4, and a surface drain 3 is installed in the ground 1, and the upper end of the surface drain 3 is located on the same plane as the ground 1; the hidden floor drain 5 is installed in the sink 4;

[0052] 2. Apply cement slurry on the wall surface 2 of the toilet to form the first waterproof cement slurry layer 21; then apply cement on the end of the bottom surface of the sink tank 4 close to the wall surface 2 and the side wall of the sink tank 4 connected to this end Mud forms the second waterproof cement slurry layer 6, and the first waterproof cement slurry layer 21 is connected to the second waterproof cement slurry layer 6;

[0053] 3. Make an R angle at the corner of the first waterproof cement slurry layer 21 and the second waterproof cement slurry layer 6;

[0054] 4. Use cement mortar to level the bottom sur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap