Intelligent coal mine fully mechanized coal mining face spray and aspirating control system

A technology for fully mechanized mining face, spray dust reduction, applied in general control system, control/regulation system, program control and other directions, can solve problems such as shortening the service life of precision instruments, accelerating mechanical wear, pneumoconiosis, etc. Ease of use, installation and maintenance, and the effect of reducing dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further illustrate the inventive concept of the present invention, the specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

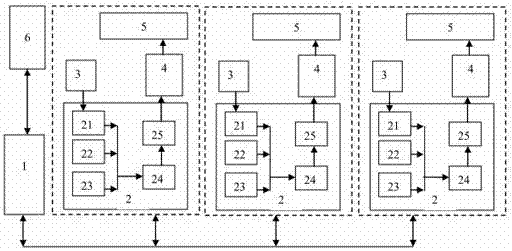

[0013] Such as figure 1 As shown, an intelligent coal mine fully mechanized mining face spray dust control system according to the present invention includes a positioning monitoring controller 1, several node spray dust control controllers 2, an infrared emission sensor 3, an explosion-proof electric ball valve 4, a spray The sprinkler head 5 and the well monitoring terminal 6 are composed of: the positioning monitoring controller 1 and the spray dust control controller 2 complete the data exchange of control signals and working status through wireless communication, and transmit the working status of the spray dust control controller 2 to The monitoring terminal 6 on the well carries out real-time display; the spray nozzle 5 is connected with the explosion-proof elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com