Blending agent for blending of edible oil

An edible oil and blending technology, applied in the directions of edible oil/fat, application, food science, etc., can solve the problem of not being very effective, and achieve the effect of increasing quality and flavor, good regulation and promotion, and improving quality and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

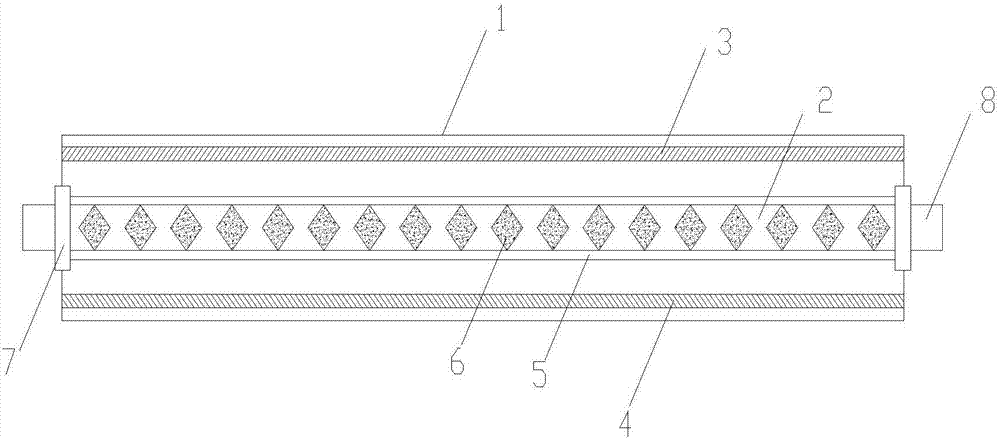

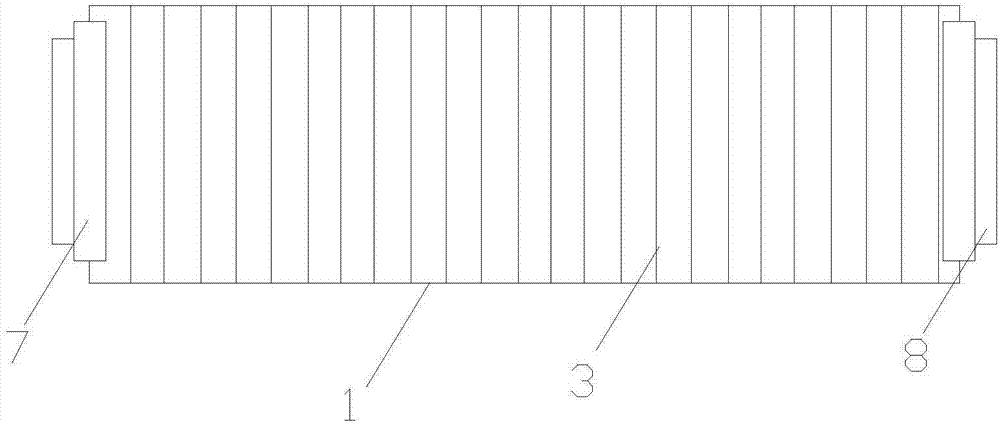

Image

Examples

Embodiment 1

[0045] A blending agent for blending edible oils, prepared from the following components: wild chrysanthemum flower extract, lycopene, vitamin E, honey, activated carbon, ginkgo oil, Codonopsis pilosula, wolfberry, dogwood, hawthorn, angelica, astragalus, Poria cocos, licorice, Atractylodes macrocephala, cassia twig, tangerine peel, pinellia chinensis, white peony root, amomum, acesulfame potassium, citric acid, dibutyl hydroxytoluene, sorbic acid, xylitol;

[0046] A blending agent for cooking oil blending, the components are calculated by mass fraction: 3 parts of wild chrysanthemum flower extract, 1 part of lycopene, 3 parts of vitamin E, 1 part of honey, 2 parts of activated carbon, 3 parts of ginkgo oil, Codonopsis 1 part, wolfberry 0.5 part, dogwood 0.5 part, hawthorn 0.3 part, angelica 0.2 part, astragalus root 0.1 part, poria cocos 0.1 part, licorice 1 part, atractylodes macrocephala 0.1 part, cassia twig 0.3 part, tangerine peel 0.2 part, pinellia 0.1 part , 0.1 part ...

Embodiment 2

[0070] A blending agent for blending edible oils, prepared from the following components: wild chrysanthemum flower extract, lycopene, vitamin E, honey, activated carbon, ginkgo oil, Codonopsis pilosula, wolfberry, dogwood, hawthorn, angelica, astragalus, Poria cocos, licorice, Atractylodes macrocephala, cassia twig, tangerine peel, pinellia chinensis, white peony root, amomum, acesulfame potassium, citric acid, dibutyl hydroxytoluene, sorbic acid, xylitol;

[0071] A blending agent for cooking oil blending, the components are calculated by mass fraction: 5 parts of wild chrysanthemum flower extract, 3 parts of lycopene, 5 parts of vitamin E, 3 parts of honey, 8 parts of activated carbon, 5 parts of ginkgo oil, 3 parts of Codonopsis, 2 parts of wolfberry, 1 part of dogwood, 0.8 part of hawthorn, 0.5 part of angelica, 0.3 part of astragalus, 0.3 part of Poria cocos, 2 parts of licorice, 0.3 part of Atractylodes macrocephala, 0.5 part of cassia twig, 0.8 part of tangerine peel, 0...

Embodiment 3

[0095] A blending agent for blending edible oils, prepared from the following components: wild chrysanthemum flower extract, lycopene, vitamin E, honey, activated carbon, ginkgo oil, Codonopsis pilosula, wolfberry, dogwood, hawthorn, angelica, astragalus, Poria cocos, licorice, Atractylodes macrocephala, cassia twig, tangerine peel, pinellia chinensis, white peony root, amomum, acesulfame potassium, citric acid, dibutyl hydroxytoluene, sorbic acid, xylitol;

[0096]A blending agent for cooking oil blending, the components are calculated by mass fraction: 4 parts of wild chrysanthemum extract, 2 parts of lycopene, 4 parts of vitamin E, 2 parts of honey, 5 parts of activated carbon, 4 parts of ginkgo oil, Codonopsis 2 parts, wolfberry 1.5 parts, dogwood 0.8 parts, hawthorn 0.5 parts, angelica 0.4 parts, astragalus 0.2 parts, Poria cocos 0.2 parts, licorice 1.5 parts, Atractylodes macrocephala 0.2 parts, cinnamon sticks 0.4 parts, tangerine peel 0.5 parts, pinellia 0.2 parts , 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com