Preparation of aminopeptidase and application of aminopeptidase in protein debitterizing

A technology of aminopeptidase and protein, applied in the field of enzyme engineering, can solve problems affecting food quality and restricting applications, and achieve the effects of improving flavor and quality, reducing bitterness, and mild debittering conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Construction of recombinant bacteria expressing aminopeptidase

[0052] Aminopeptidase derived from Aspergillus oryzae, Aspergillus flavus, Aspergillus sojae, Aspergillus minisclerotigenes, Aspergillus transmontanensis, Aspergillus novoparasiticus, Aspergillus arachidicola (the accession number or gene number on the NCBI corresponding to the aminopeptidase is respectively NCBI accession number: XP_001825745.1 , GenBank: RAQ51025.1, NCBI accession number: Q8J2N2, GenBank: KAB8272165.1, GenBank: KAE8313457.1, GenBank: KAB8217617.1, GenBank: KAE8342201.1), construct recombinant bacteria respectively, and the specific implementation steps are as follows:

[0053] (1) Construction of recombinant plasmids

[0054] Using chemical methods to synthesize the gene encoding aminopeptidase AoAPase whose nucleotide sequence is shown in SEQ ID NO.2 on the vector pPIC9K, directly obtain the recombinant plasmid pPIC9K-AoAPase, and transform the recombinant plasmid into Esc...

Embodiment 2

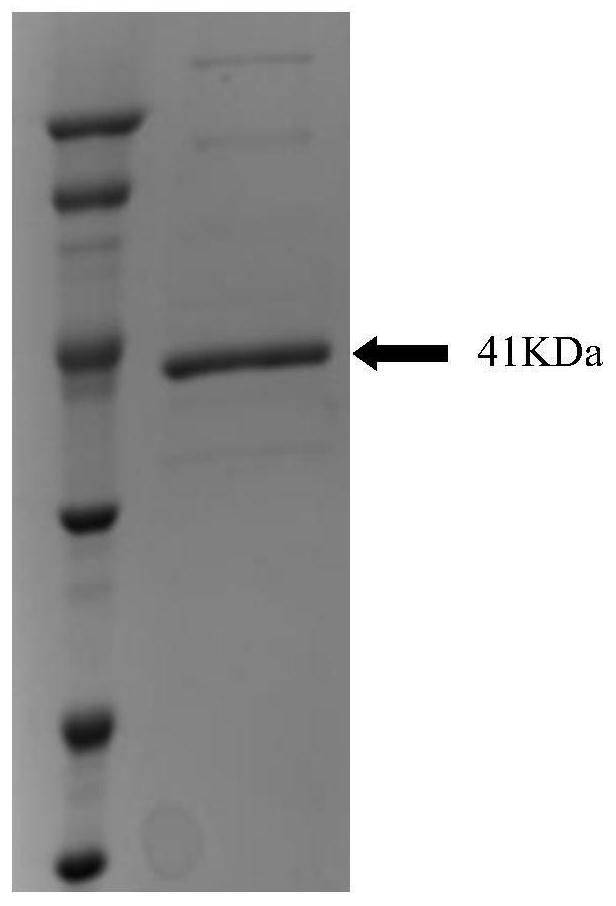

[0059] Embodiment 2: Recombinant bacterial expression aminopeptidase

[0060] (1) Using the recombinant bacteria constructed in Example 1, shake the flask to ferment to produce enzyme.

[0061] Pick large single colonies from the MD plate into labeled small tubes, add 4mL of BMGY medium to each small tube, and culture for 2-3 days. When there is obvious bacterial precipitation at the bottom of the small tube, centrifuge at 5000rpm for 5min, pour off the supernatant in an ultra-clean bench, add 2mL of BMMY medium, add 1% methanol after resuspension, and incubate at 30°C for 2-3 days. 24h added 1% volume of methanol. Measure the enzyme activity and protein content of the bacterial solution, select 5-10 transformants with enzyme activity, and then carry out shake flask screening.

[0062] Add 5-10 transformants with high enzyme activity to 50 mL of BMGY medium and culture for 2-3 days. When the bottom of the shake flask has obvious bacterial precipitation, centrifuge at 5000rp...

Embodiment 3

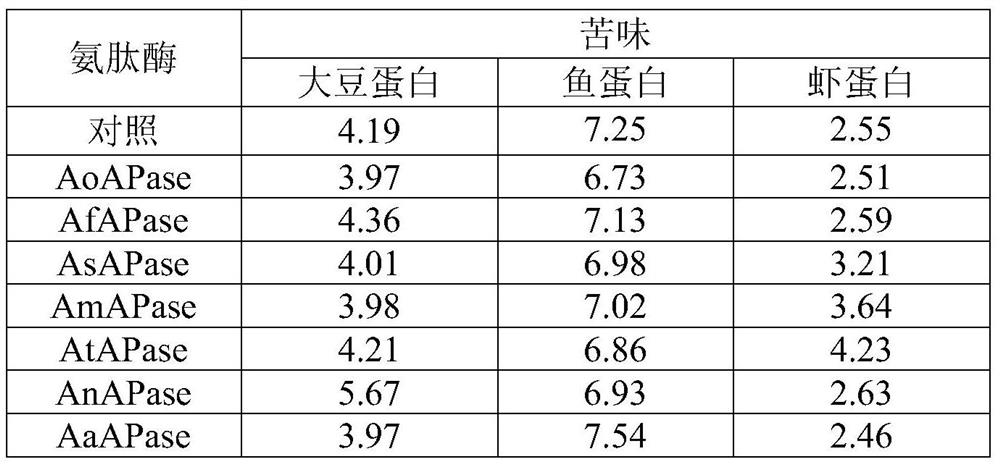

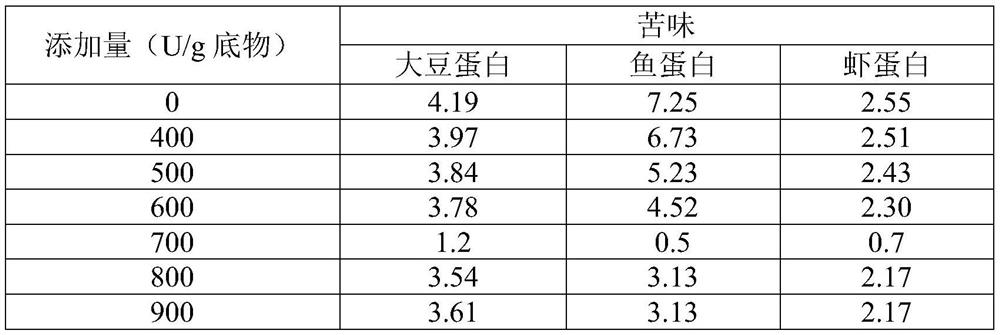

[0067] Example 3: Application of different aminopeptidases in protein debittering

[0068] Embodiment 2 obtains the aminopeptidase of different sources and carries out debittering to albumen:

[0069] Weigh soybean protein, fish protein, and shrimp protein to prepare 100mL protein solution with a concentration of 20g / L, add aminopeptidase 400U / g substrate to the protein solution, and use a constant temperature water bath shaker to maintain the hydrolysis temperature at 50°C and 150rpm enzyme Decompose for 5 hours, take a boiling water bath for 10 minutes, cool for a period of time, centrifuge the enzymolysis solution at 8000 rpm for 10 minutes, and take the supernatant to test the bitterness.

[0070] The results are shown in Table 2: the aminopeptidases from different sources obtained in Example 2 have significant differences in debittering effects on different types of proteins. Among them, aminopeptidase AoAPase has a more obvious debittering effect on soybean protein, fis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com