A hydrogenation catalyst and its pretreatment method, method and application of improving the desulfurization activity of the hydrogenation catalyst

A technology of hydrogenation catalyst and performance, applied in the field of hydrogenation catalyst pretreatment, can solve the problems of low hydrodesulfurization activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

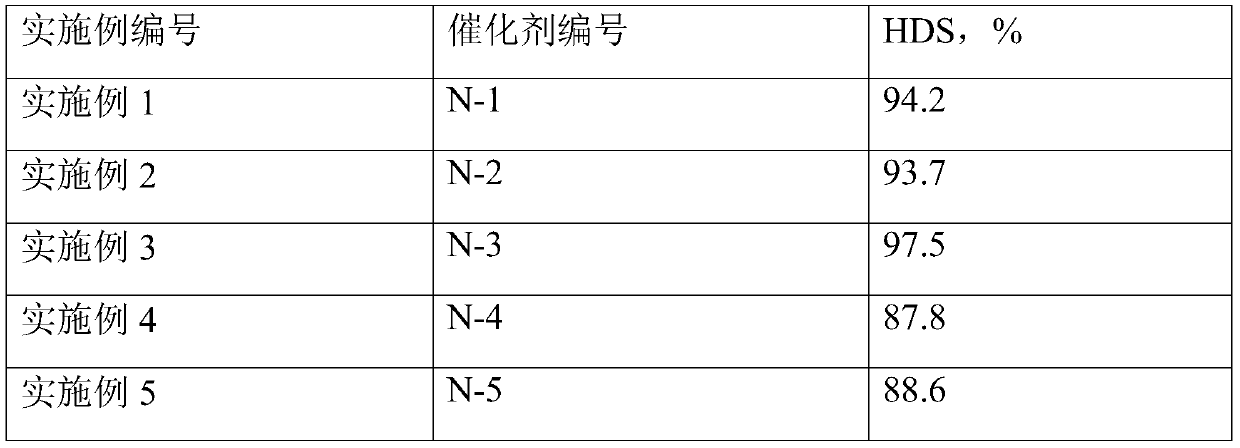

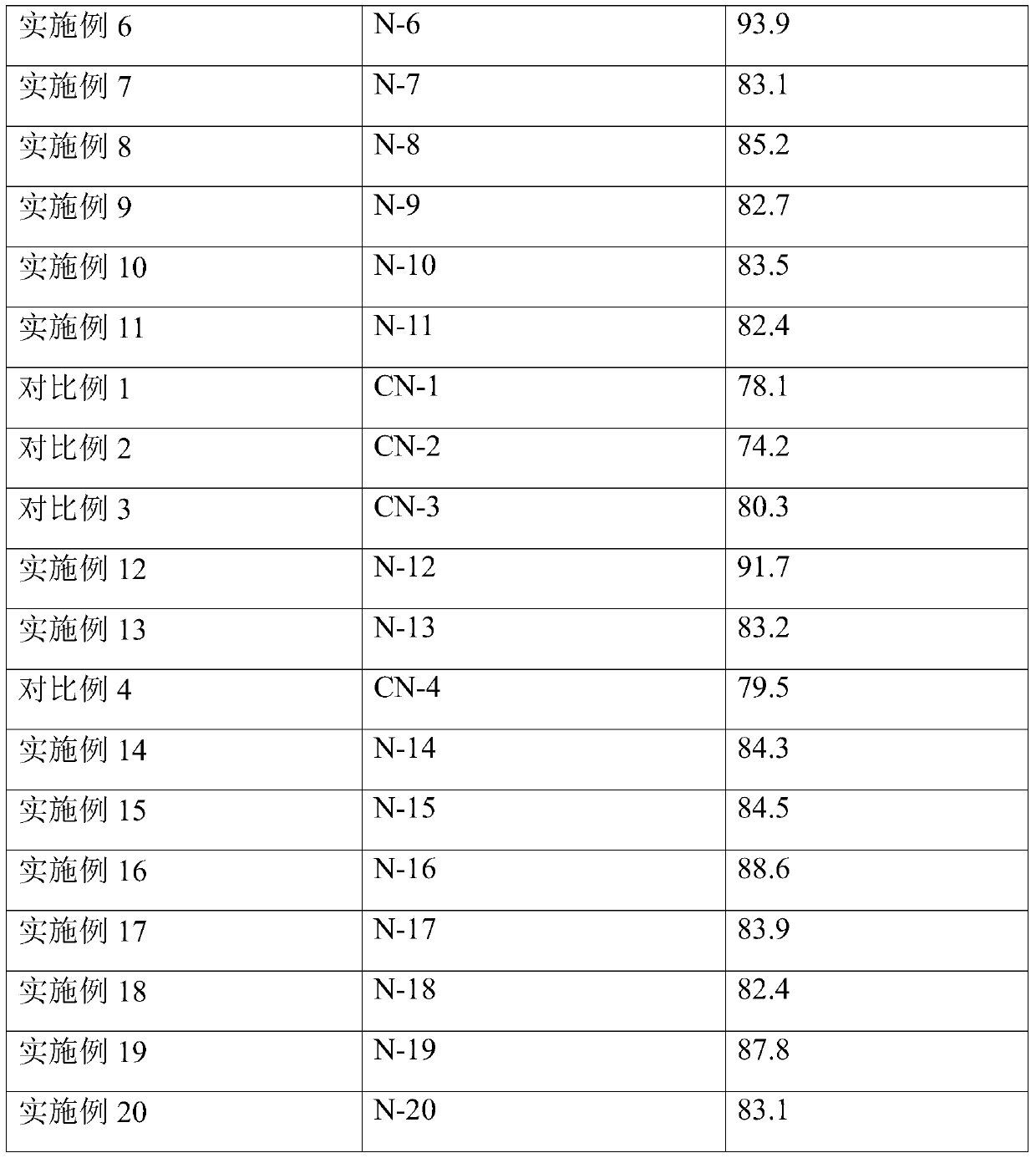

Examples

Embodiment approach

[0046] According to one embodiment, the method provided by the present invention comprises the following steps: (1) using a mixed gas containing hydrogen and hydrogen sulfide to sulfide the hydrogenation catalyst; (2) lowering the temperature of the sulfided catalyst obtained in step (1) , and then introduce a mixed gas containing inert gas and oxygen to contact with the sulfided catalyst for passivation; (3) unload the catalyst obtained in step (2) from the sulfidation reactor, and then impregnate an equal volume of solution containing organic oxygen-containing compounds (4) In an inert gas atmosphere, the catalyst obtained in step (3) is heat-treated at a higher temperature.

[0047] The present invention also provides the pretreated hydrogenation catalyst obtained by the above method. Using the method provided by the invention can obviously improve the desulfurization activity of the hydrogenation catalyst.

[0048] The catalyst treated according to the method of the prese...

Embodiment 1

[0053] Put 20 mL of Catalyst 1 particles with a diameter of 1-3 mm into the constant temperature zone of the reactor of the small-scale hydrogenation test device, and fill the upper and lower parts of the reactor with circular ceramic balls. Then carry out following operation steps successively to carry out pretreatment to catalyst 1 particle:

[0054] (1) Using 2 volume % H 2 S+98vol%H 2 The mixed gas raises the device to an operating pressure of 1.6MPa, and the gas volume space velocity is 500h -1 , and then use 1h to raise the reactor temperature from room temperature to 230°C, then keep the temperature for 2h, then use 2h to raise the reactor temperature to 320°C, and then vulcanize at 320°C for 12 hours.

[0055] (2) After the temperature of the reactor drops to 50°C, switch the sulfide gas to 0.5% by volume O 2 +99.5vol%N 2 , the pressure is 1.6MPa, the gas volume space velocity is 600h -1 , Purge for 6h for passivation.

[0056] (3) After the passivation, the obta...

Embodiment 2

[0059] Put 20 mL of Catalyst 1 particles with a diameter of 1-3 mm into the constant temperature zone of the reactor of the small-scale hydrogenation test device, and fill the upper and lower parts of the reactor with circular ceramic balls. Then carry out following operation steps successively to carry out pretreatment to catalyst 1 particle:

[0060] (1) Using 8 volume% H 2 S+92vol%H 2 The mixed gas raises the device to an operating pressure of 0.6MPa, and the gas volume space velocity is 1000h -1 , and then use 1.5h to raise the reactor temperature from room temperature to 250°C, then keep the temperature for 1.5h, then use 2.5h to raise the reactor temperature to 380°C, and then vulcanize at 380°C for 4 hours.

[0061] (2) After the temperature of the reactor drops to 30°C, switch the sulfide gas to 5% by volume O 2 +95vol%N 2 , the pressure is 0.6MPa, the gas volume space velocity is 900h -1 , Purge for 3h for passivation.

[0062] (3) After the passivation is compl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap