High-speed board loading and unloading machine capable of realizing automatic transferring of material boxes and board loading and unloading method

A technology of material box switching and board retraction, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of frequent switching of material boxes, inconvenience, etc., to solve scratches and creases, increase production, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

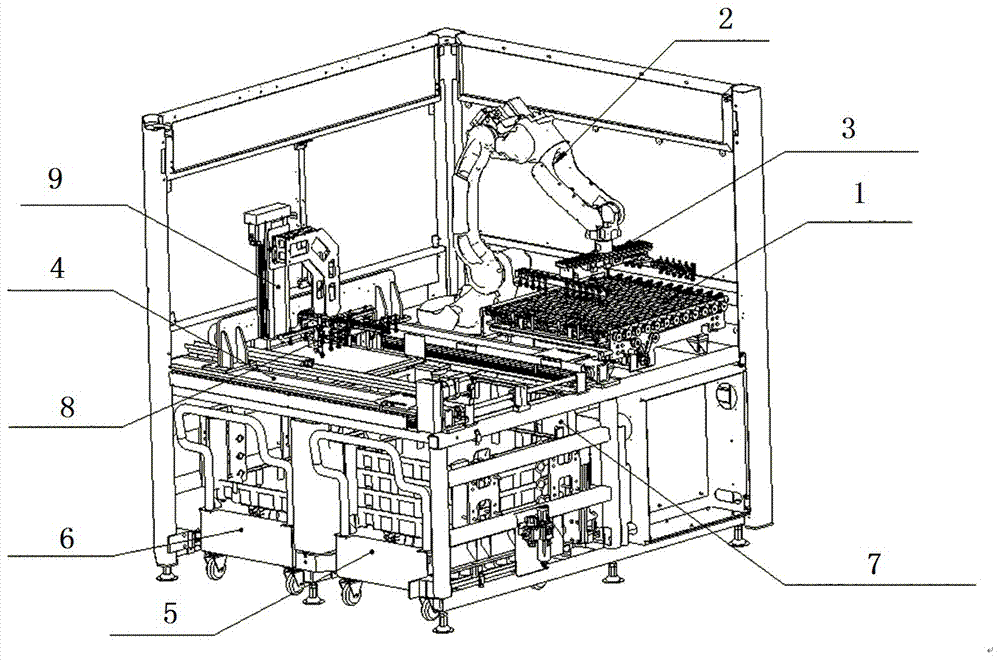

[0035] Such as figure 1 As shown, a high-speed retractable board machine capable of automatic material box switching includes a frame on which a PCB transmission mechanism and a retractable board mechanism are arranged in sequence, and it is characterized in that

[0036] One side of the PCB transfer mechanism 1 is provided with a six-axis robot adsorption system, the six-axis robot adsorption system includes a six-axis robot 2 and a suction cup hand 3 arranged on the six-axis robot, and the six-axis robot adsorption system is used for The PCB on the PCB transfer mechanism 1 is transported to the retractable board mechanism;

[0037] The retractable board mechanism includes a retractable board platform located at the top of the frame, and the retractable board platform includes a first magazine station and a second magazine station, and the first magaz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com