Method for preparing ultrafine aluminum dihydrogen phosphate powder in alumina rock

A technology for granular aluminum dihydrogen phosphate and aluminous rock, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of slow reaction, high temperature, influence, etc., and achieve full and thorough reaction, fast reaction and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

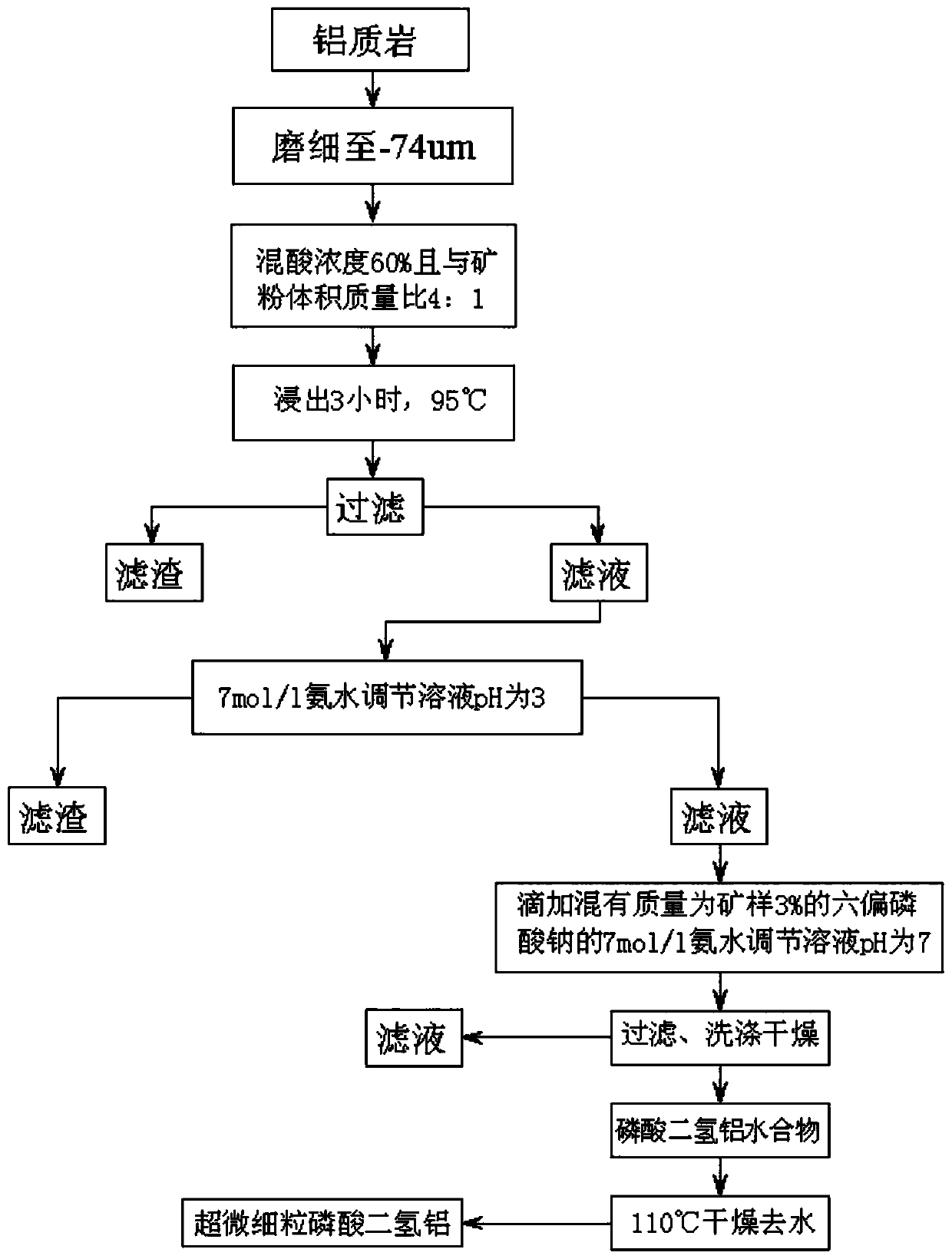

Image

Examples

Embodiment 1

[0039] A method for preparing ultrafine aluminum dihydrogen phosphate powder in alumina rock, the method comprising the following steps:

[0040] (1) Using alumina rock as raw material, Al 2 o 3 The content is 57.7%, and the alumina rock is used as raw material. After crushing it with a jaw crusher, the crushed ore powder is crushed again with a disc crusher, and then the particle size is reduced to below 74um by a vibrating mill; the alumina rock is finely ground Finally, the specific surface area is increased to make the reaction fully and completely, the reaction is faster, the efficiency is higher, and it is conducive to the more thorough leaching of Al2O3 in the alumina rock;

[0041] (2) After drying the mineral powder sample ground in step (1), the mixed solution of hydrochloric acid and phosphoric acid and the dried mineral powder are placed in a water bath in proportion to stirring, and the mixed acid concentration is 60% in the mixed solution used, And the volume r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com