Method and device for heterogeneously catalyzing oxidation of COD in wastewater by using hydrogen peroxide

A technology for heterogeneous catalysis and oxidation of wastewater, which is applied in chemical instruments and methods, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of large amount of hydrogen peroxide and reuse of liquid Fenton reagent Difficulties and other problems, to achieve the effect of reducing waste, improving COD removal rate, and reducing the amount of hydrogen peroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

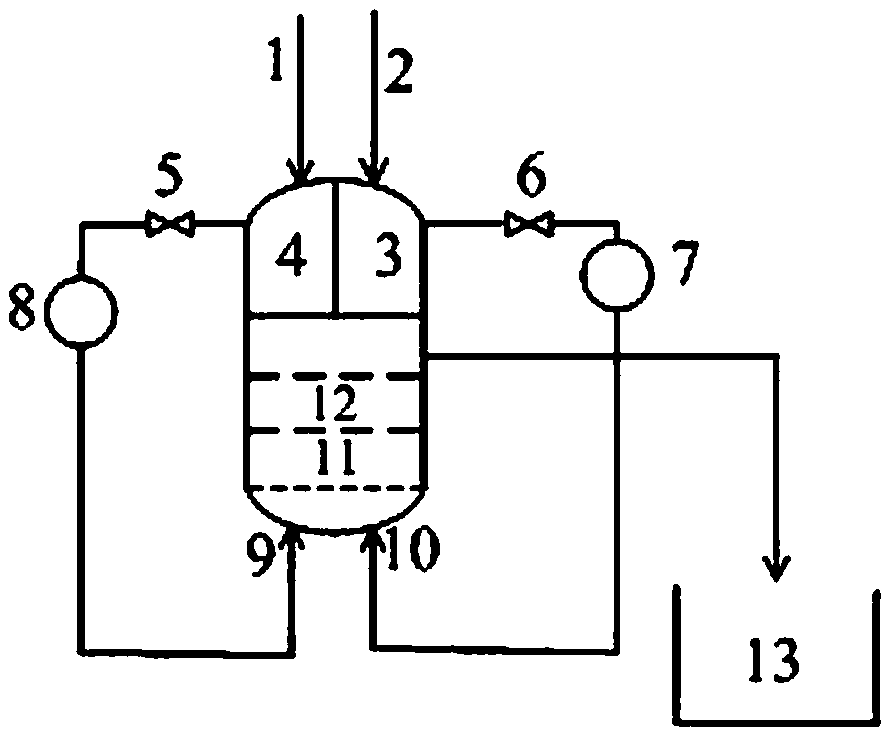

[0039] A hydrogen peroxide heterogeneous catalytic oxidation wastewater treatment device (fixed bed, such as figure 1 shown), specifically a wastewater oxidation tower, including a hydrogen peroxide storage tank 3 and a wastewater storage tank 4 located at the upper part of the tower body, a fixed bed solid catalyst layer 12 in the middle of the tower body and a water distributor 11 at the lower part of the tower body;

[0040] The waste water tank 4 is connected to the waste water inlet pipe 1, and the hydrogen peroxide tank 3 is connected to the hydrogen peroxide water inlet pipe 2;

[0041] The waste water tank 4 is connected with the waste water inlet 9 at the bottom of the waste water oxidation tower, and a waste water drain valve 5 and a waste water delivery pump 8 are arranged on the connecting pipeline;

[0042] The hydrogen peroxide tank 3 is connected with the hydrogen peroxide inlet 10 at the bottom of the waste water oxidation tower, and a hydrogen peroxide drain v...

Embodiment 2

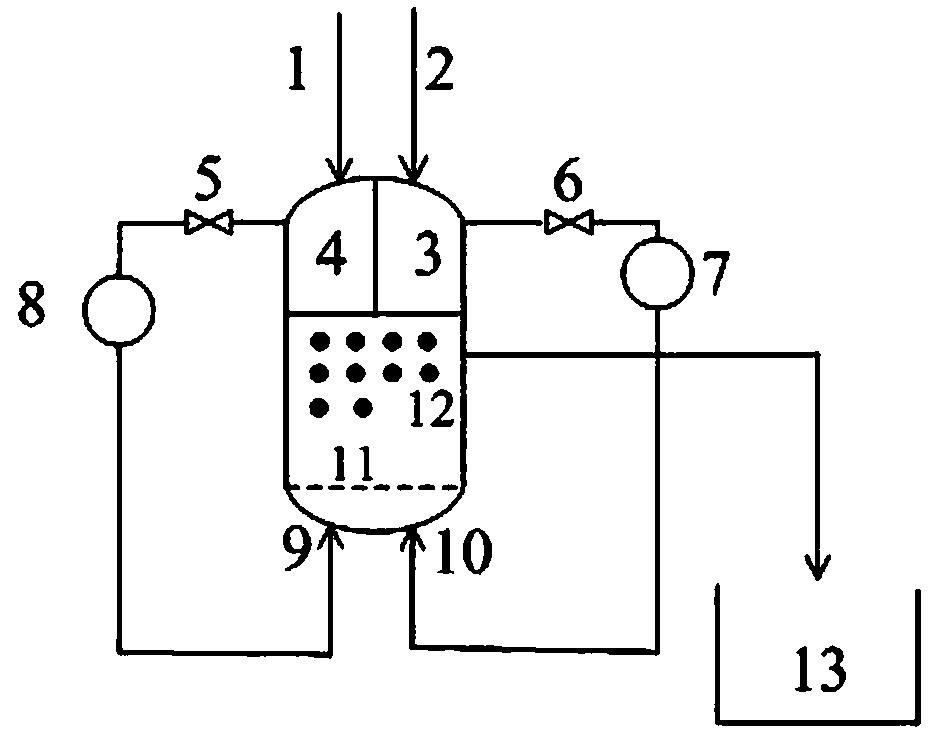

[0045] A hydrogen peroxide heterogeneous catalytic oxidation wastewater treatment device (fluidized bed, such as figure 2 shown),

[0046] Specifically, it is a waste water oxidation tower, including a hydrogen peroxide storage tank 3 and a waste water storage tank 4 located at the upper part of the tower body, a fluidized bed solid catalyst layer 12 at the middle part of the tower body and a water distributor 11 at the lower part of the tower body;

[0047] The waste water tank 4 is connected to the waste water inlet pipe 1, and the hydrogen peroxide tank 3 is connected to the hydrogen peroxide water inlet pipe 2;

[0048] The waste water tank 4 is connected with the waste water inlet 9 at the bottom of the waste water oxidation tower, and a waste water drain valve 7 and a waste water delivery pump 8 are arranged on the connecting pipeline;

[0049] The hydrogen peroxide tank 3 is connected with the hydrogen peroxide inlet 10 at the bottom of the waste water oxidation tower...

Embodiment 3

[0057] A method for hydrogen peroxide heterogeneously catalyzed oxidation of COD in wastewater (using the device of Embodiment 1), the steps are:

[0058] (1) Pass the wastewater with a COD concentration of 100 mg / L through the wastewater inlet pipe 1, and the hydrogen peroxide with a mass concentration of hydrogen peroxide of 27.5% through the hydrogen peroxide inlet pipe 2 to the hydrogen peroxide storage tank 3 and the wastewater at the upper part of the wastewater oxidation tower. In the storage tank 4; then the liquid in the hydrogen peroxide storage tank 3 is passed through the hydrogen peroxide drain valve 6 and the hydrogen peroxide delivery pump 7, and enters the inlet of the water distributor 11 at the lower part of the tower body by the hydrogen peroxide inlet 10; the liquid in the waste water storage tank 4 is drained through the waste water The valve 5 and the wastewater delivery pump 8 enter the inlet of the water distributor 11 at the lower part of the tower from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com