Modified plastic granules and homogenizing method thereof

A plastic granule modification technology, which is applied in the field of homogenization of the above-mentioned modified plastic granule, can solve the problems of high operating cost and complex structure, and achieve the effects of reducing production cost, alleviating pollution, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The modified plastic granules include the following components by weight percentage: 55% tire rubber granules, 22% polyurethane waste granules, 13% calcium powder, 5% stearic acid amine, and 5% additives.

Embodiment 2

[0031] The modified plastic granules comprise the following components in weight percent: 65% of tire rubber granules, 20% of polyurethane waste granules, 10% of calcium powder, 2% of stearic acid amine, and 3% of additives.

Embodiment 3

[0033] The modified plastic granules comprise the following components by weight percentage, 50% of tire rubber granules, 25% of polyurethane waste granules, 15% of calcium powder, 5% of stearic acid amine, and 5% of additives.

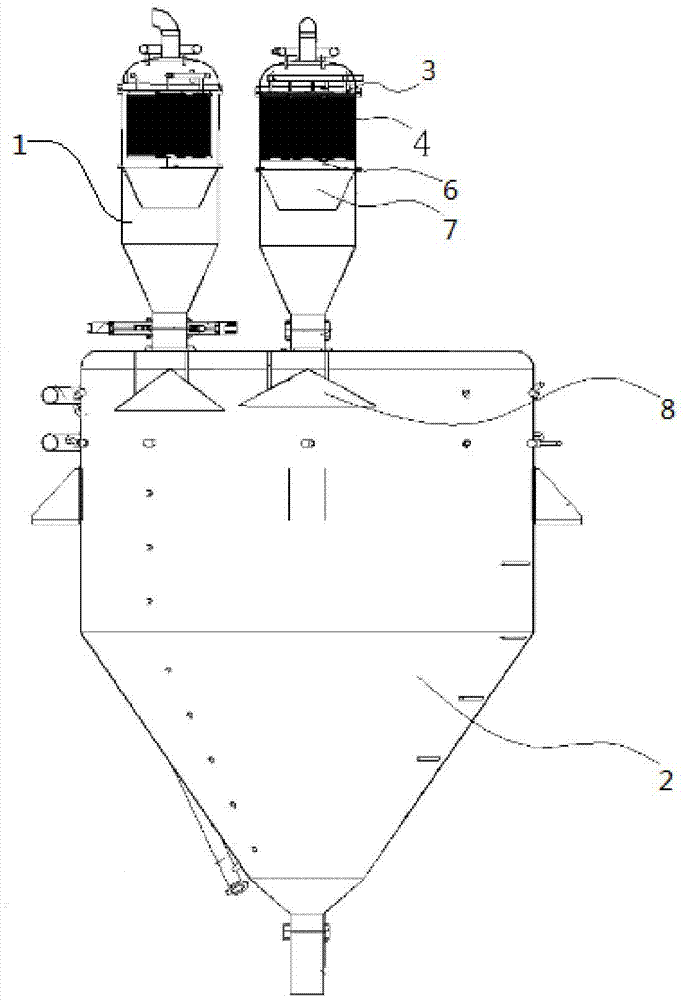

[0034] see Figure 1 to Figure 3 According to the main technical scheme adopted by the homogenization method of a kind of modified plastic particles provided by the present invention: comprise the following steps:

[0035] 1) First collect polyurethane waste and tire rubber waste, and dry them separately, and then crush them into granules for use;

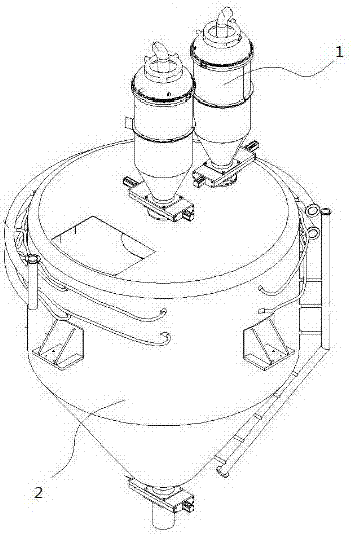

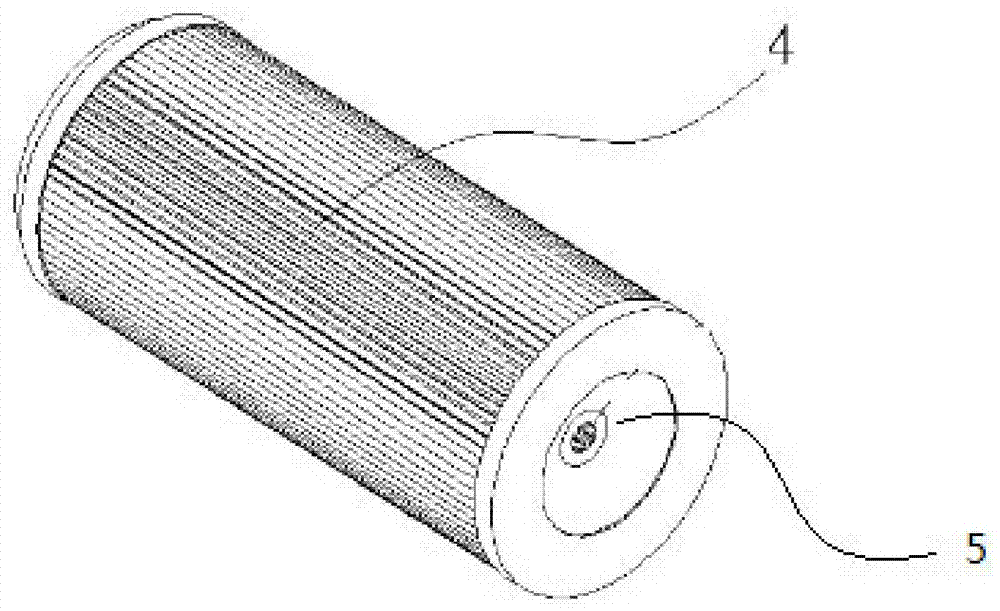

[0036] 2) Input the pulverized polyurethane waste granules, tire rubber granules, calcium powder, stearic acid amine and additives into the proportioning device on the plastic homogenizer respectively through pipelines, and pass multiple materials in the proportioning device The bin 1 is transferred to the main bin body 2 according to the mass percentage for preliminary homogenization, and then transferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com