Microwave assisted process of synthesizing tetraphenyl porphyrin inside ionic liquid

A technology of tetraphenylporphyrin and ionic liquid, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc. Long time and other problems, to achieve the effect of good selectivity, simple process, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

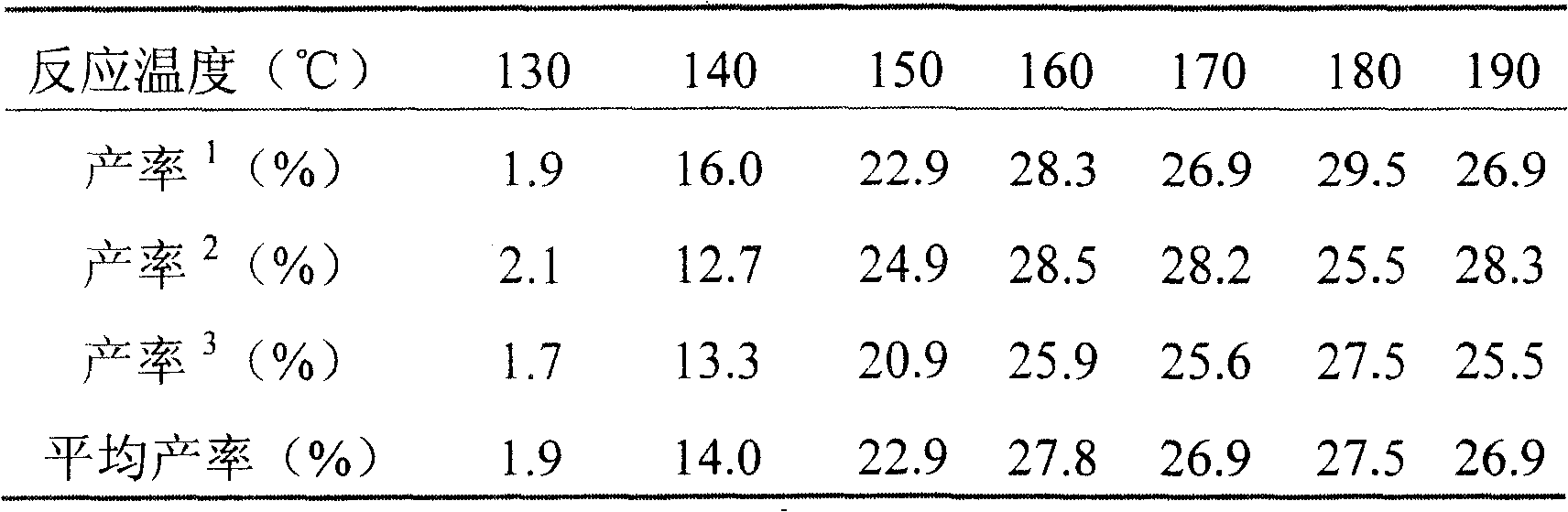

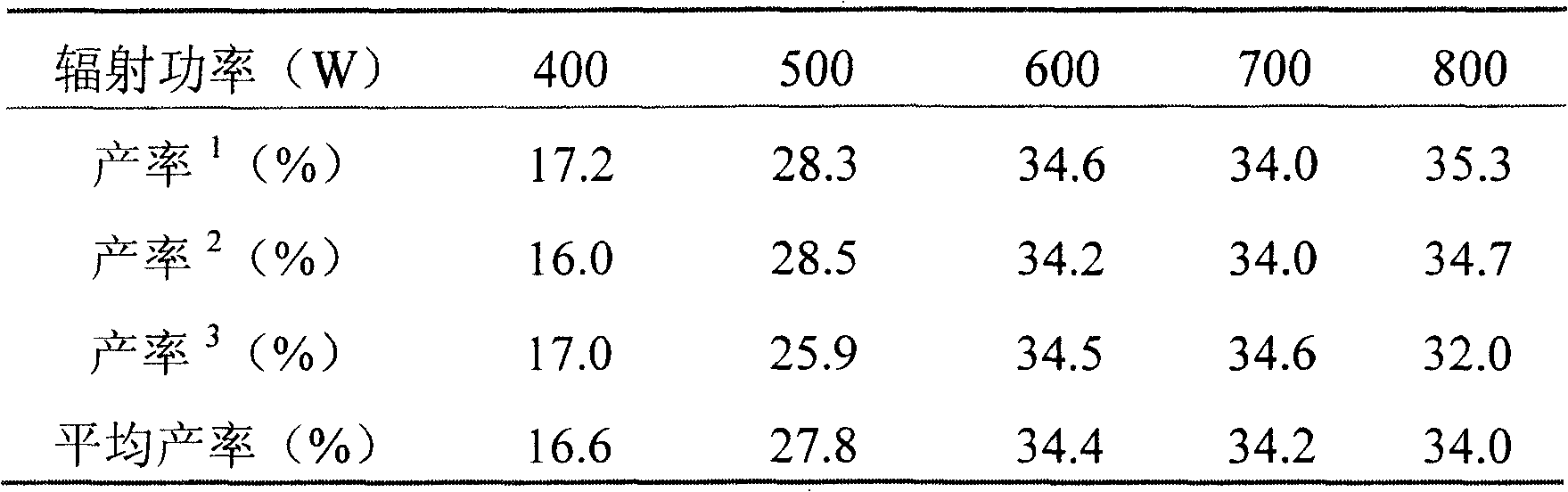

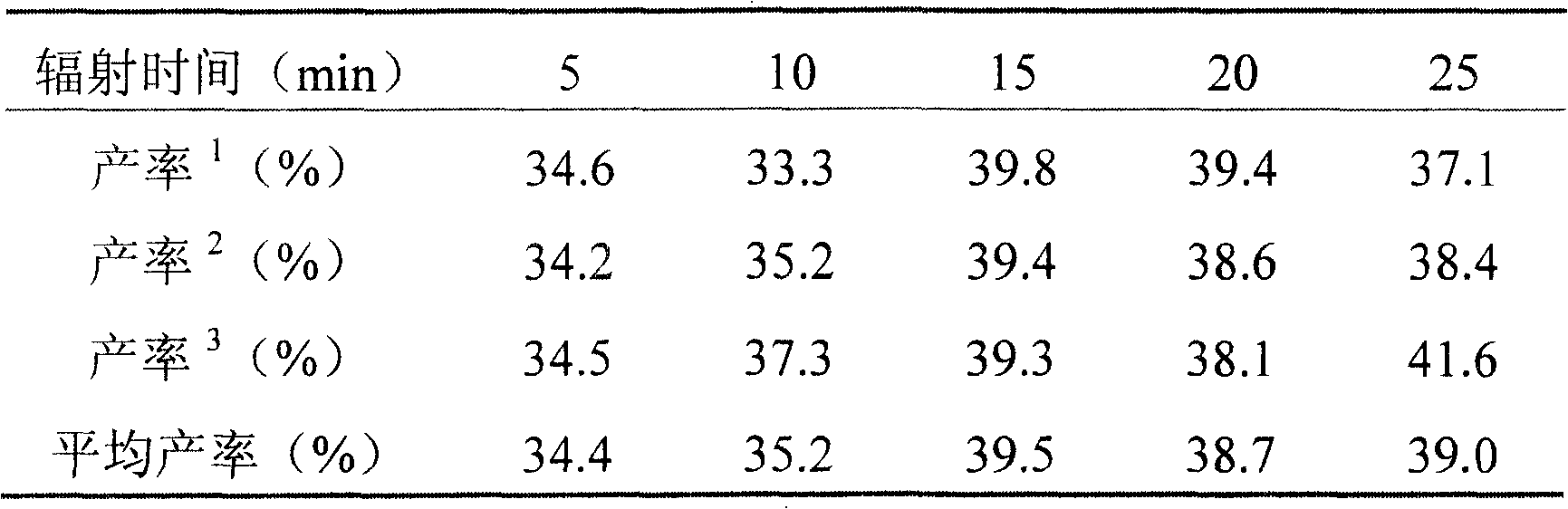

Method used

Image

Examples

Embodiment 1

[0049] 1.0038g (3×10 -4 mol) silicotungstic acid, 5.8965g (0.026mol) ionic liquid BMIBF 4 , 1.0612g (0.01mol) of benzaldehyde and 0.6709g (0.01mol) of pyrrole were added to a 25mL two-necked round-bottomed flask connected with a condenser tube, and at a microwave power of 600W and a reaction temperature of 160°C, irradiated continuously for 15min, and the reaction mixture became Purple-black viscous liquid, immediately add 100ml of absolute ethanol, let stand for 24h. Suction filtration, the filter cake was washed 3 times with absolute ethanol to remove unreacted reactants. Vacuum drying at 50°C for 24 hours gave a purple solid, which was purified by column chromatography to give a purple crystal. The yield was 64.3%.

Embodiment 2

[0051] 0.2576g (7.7×10 -5 mol) silicotungstic acid, 4.5358g (0.02mol) ionic liquid BMIBF 4 , 1.0612g (0.01mol) of benzaldehyde and 0.3355g (0.005mol) of pyrrole were added to a 25mL two-necked round-bottomed flask connected with a condenser, and the microwave power was fixed at 500W. At a reaction temperature of 150°C, irradiate continuously for 5min. The reaction mixture turned into a purple-black viscous liquid, which was immediately added with 100ml of absolute ethanol and allowed to stand overnight. Suction filtration, the filter cake was washed 3 times with absolute ethanol to remove unreacted reactants. Vacuum-dried at 45°C for 24 hours to obtain a purple solid, which was purified by column chromatography to obtain a purple crystal. The yield was 20.3%.

Embodiment 3

[0053] 1.3384g (4×10 -4 mol) silicotungstic acid, 6.8038g (0.03mol) ionic liquid BMIBF 4 , 1.0612g (0.01mol) of benzaldehyde and 1.0064g (0.015mol) of pyrrole were added to a 25mL two-necked round-bottomed flask connected with a condenser tube, and irradiated continuously for 25min at a microwave power of 800W and a reaction temperature of 190°C. The reaction mixture turned into a purple-black viscous liquid, which was immediately added with 100ml of absolute ethanol and allowed to stand overnight. Suction filtration, the filter cake was washed 3 times with absolute ethanol to remove unreacted reactants. Vacuum drying at 55°C for 30 h gave a purple solid, which was purified by column chromatography to give a purple crystal. The yield was 37.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com