Environment-friendly anticorrosive coating for ships and preparation method thereof

An anti-corrosion coating and environmental protection technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of ship structural materials being easily corroded, marine biological corrosion, etc., and achieve improved anti-corrosion capabilities and efficient anti-corrosion The effect of detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

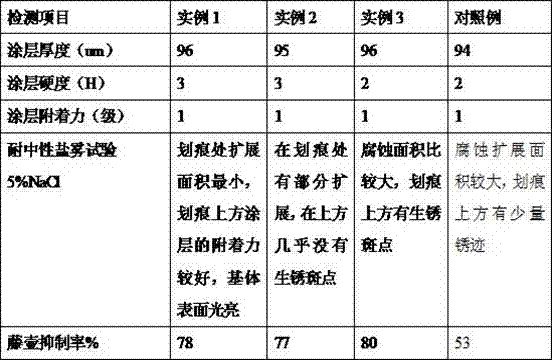

Examples

example 1

[0024] Take marine plants and wash them twice, put them into a beater, crush them and beat them for 20 minutes to obtain a beating solution; mix the beating solution and absolute ethanol at a mass ratio of 1:10, put them into a flash extractor, and extract at 60°C for 10 minutes. Filter to obtain filter residue and extract, combine extract after filter residue is repeatedly extracted 2 times, place the combined extract in a flash concentrator and concentrate to 20% of the volume of the stock solution to obtain a concentrated solution; get 3g capsaicin, 10g coral reef, Put 30g of expanded vermiculite into a grinder and grind for 30min, cross a 100-mesh sieve to obtain a composite powder, get 20g of the composite powder and add it to 100g of concentrated liquid, stir at 300r / min for 15h to obtain a composite feed liquid; mix the composite feed liquid, Add 3g gelatin and 1g silane coupling agent KH-602 into 300g mass fraction of 1% chitosan solution, stir at 300r / min for 3h to obt...

example 2

[0027] Take marine plants and wash them twice, put them into a beater, crush and beat them for 25 minutes to obtain a beating solution; mix the beating solution and absolute ethanol at a mass ratio of 1:12, put them into a flash extractor, and extract at 65°C for 12 minutes. Filter to obtain filter residue and extract, combine extract after filter residue is repeatedly extracted 2 times, place the combined extract in a flash concentrator and concentrate to 25% of the volume of the stock solution to obtain a concentrated solution; get 4g capsaicin, 15g coral reef, 40g of expanded vermiculite is packed into a grinder and ground for 35min, and crossed a 100 mesh sieve to obtain a composite powder. Get 25g of the composite powder and add it to 150g of concentrated liquid, and stir at 350r / min for 17h to obtain a composite feed liquid; the composite feed liquid, Add 4g of gelatin and 1.5g of silane coupling agent KH-602 into 400g of chitosan solution with a mass fraction of 1%, and ...

example 3

[0029]The marine plants were washed with water for 3 times, put into a beater, crushed and beaten for 30 minutes to obtain a beating liquid; the beating liquid was mixed with anhydrous ethanol at a mass ratio of 1:15, put into a flash extractor, and extracted at 70°C for 15 minutes. Filter to obtain filter residue and extract, combine extract after filter residue is repeatedly extracted 3 times, place the combined extract in a flash concentrator and concentrate to 30% of the volume of the stock solution to obtain a concentrated solution; get 5g capsaicin, 20g coral reef, Put 50g of expanded vermiculite into a grinder and grind for 40min, pass through a 100-mesh sieve to obtain composite powder, get 30g of composite powder and add it to 200g concentrated liquid, stir at 400r / min for 20h to obtain composite liquid; 5g gelatin, 2g silane coupling agent KH-602, add 500g mass fraction of 1% chitosan solution, stir at 400r / min for 3-5h to obtain a mixture, put the mixture into a cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com