Rapid winding-unwinding device for water supply pipeline for fracturing for mountain land

A technology for retractable devices and pipelines, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as high center of gravity of vehicles, inconvenient transportation, large production investment, etc., to achieve uniform gravity distribution, Save labor and have strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

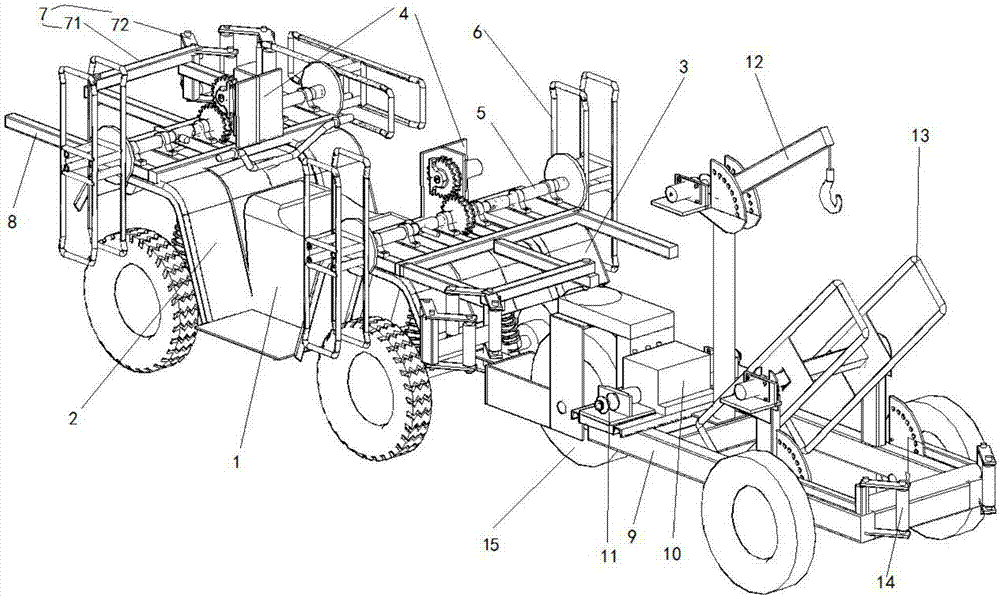

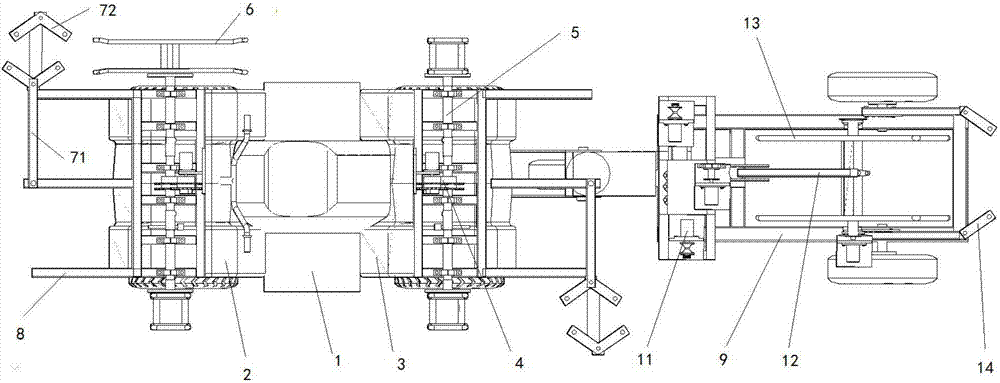

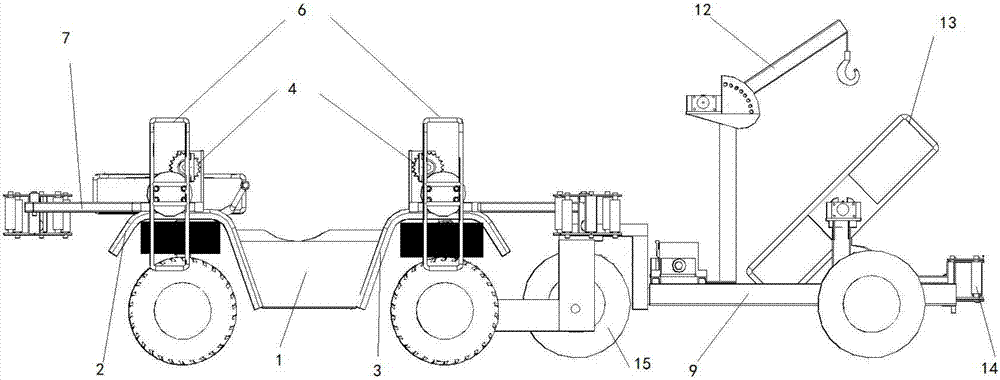

[0024] Such as figure 1 As shown, a fast retractable device for fracturing water supply pipelines for mountainous areas is composed of two parts: a large pipeline retractable system and a small pipeline retractable system. Frame 6, motor, battery, small pipeline guide bracket 7, power transmission pair 4, pipeline retractable transmission assembly 5; the fender of described four-wheel motorcycle 1 is a reinforced thickened fender, used as a support plate, respectively For the front fender 2 and the rear fender 3, the shock absorbing spring below is modified to reduce its size and strength relatively, and small pipeline retractable racks 6 are respectively provided at the upper front and rear upper parts of the quad bike 1; The small pipeline retractable rack 6 is two independent retractable racks, which are respectively installed above the front fender...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com