Method for performing flue gas mercury concentration measurement by utilizing modified high-sulfur petroleum coke

A technology of petroleum coke and mercury concentration, which is applied in the direction of color/spectral characteristic measurement, measuring device, and preparation of test samples, etc. It can solve problems such as unfavorable promotion, long measurement time, and inability to detect mercury concentration, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The invention provides a method for measuring flue gas mercury concentration using modified high-sulfur petroleum coke, which uses a cheap and efficient modified high-sulfur petroleum coke adsorbent as a substitute for activated carbon to measure flue gas mercury concentration, thereby The industrial cost of measuring mercury concentration by dry method is greatly reduced.

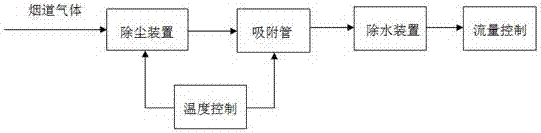

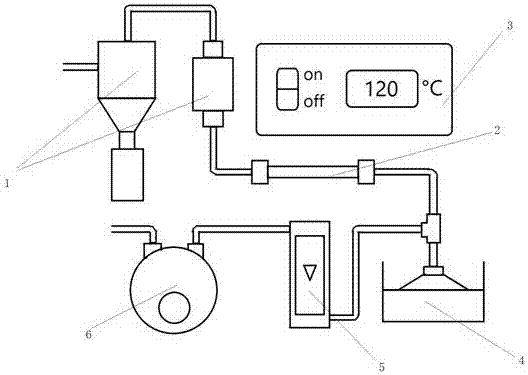

[0029] Such as a schematic diagram of the process figure 1 and physical connection diagram figure 2 As shown, the flue gas sampled from the flue first flows through the dust removal device 1 to remove the fly ash in the flue gas; The mercury is captured by the adsorbent; then flows through the water removal device 4 to remove the moisture in the flue gas; finally reaches the flow control device (rotameter 5, water ring vacuum pump 6, etc.). The temperature control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com