Power cabinet and cooling control method thereof

A technology for power cabinets and controllers, applied to electrical components, substation/distribution device casings, substation/switch layout details, etc., can solve problems such as poor contact, control component crashes, losses, etc., to achieve reasonable heat dissipation and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

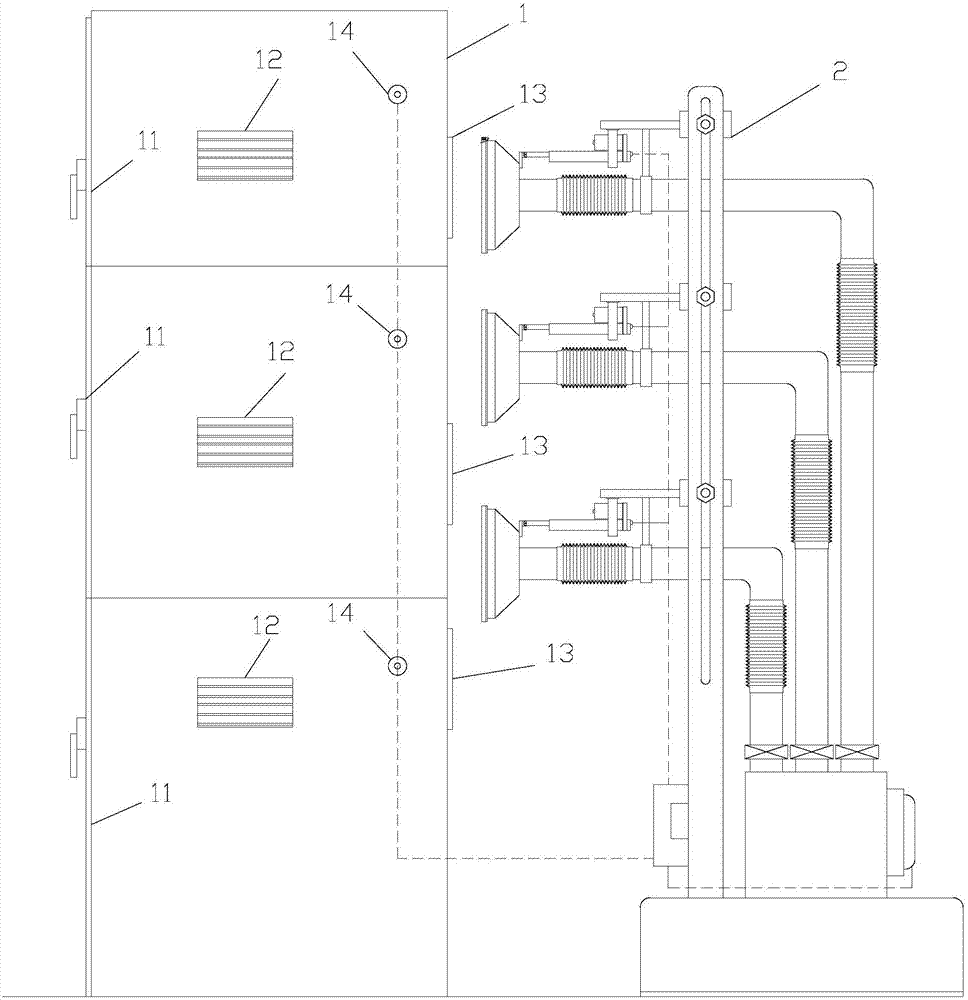

[0050] Such as figure 1 As shown, the power cabinet described in this embodiment includes a cabinet body 1 composed of N independent chambers 11 and an external heat sink 2 located on the rear side of the cabinet body 1, and each chamber 11 is provided with an air inlet window 12 And the air outlet 13, in normal times, the air inlet window 12 and the air outlet 13 can overflow hot air outwards so as to achieve the purpose of heat dissipation, the air outlet 13 is opposite to the external cooling device 2, and each chamber 11 is also provided with Temperature probe 14; It is characterized in that:

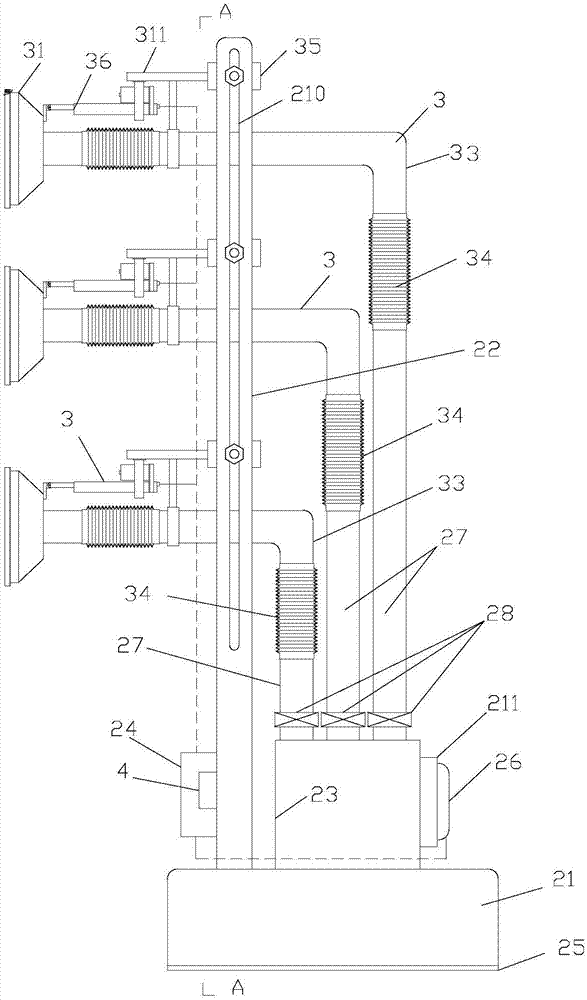

[0051] Such as figure 2 , 4 As shown, the external cooling device 2 includes a chassis 21, a bracket 22, a bellows 23, a control box 24 and N exhaust devices 3 installed on the bracket 22, each exhaust device 3 corresponds to an air outlet 13, and the chassis 21 bottom surfaces have buffer pad 25, and the effect of buffer pad 25 is to absorb the vibration that blower fan 26 prod...

Embodiment 2

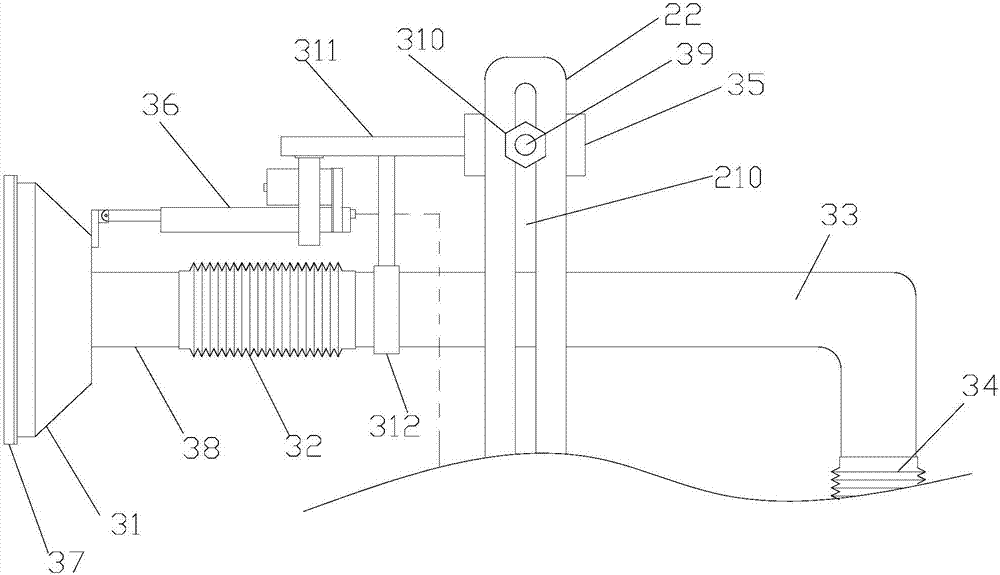

[0059] Such as Figure 5 As shown, the power cabinet described in this embodiment is substantially the same as that in Embodiment 1, the difference is that: the suction cover 31 is provided with a position sensing switch 5, and the signal of the position sensing switch 5 is also input to the controller 4. The position sensing switch 5 can sense the cabinet body. When it senses that there is a small distance X from the cabinet body (at this time, the sealing ring 37 just fits, and at the same time, the sealing ring 37 is not excessively deformed to affect the buffering capacity), The controller can stop the propulsion work of the telescopic driver 36, and the setting of this small distance X can be realized by adjusting the detection range of the position sensing switch 5, which belongs to the prior art, such as the proximity switch of Schneider or Omron; The sealing ring 37 has a plurality of inner and outer sealing lips; firstly, the plurality of sealing lips have a good seal...

Embodiment 3

[0061] Such as Figure 6 , 7 As shown, the power cabinet described in this embodiment is substantially the same as that of Embodiment 1, the difference lies in: the structure and arrangement of the sealing ring 37, that is, the front port of the suction cover 31 is provided with a ring groove 6 along the outside, The sealing ring 37 is composed of a C-shaped ring pipe section 61 and two annular pins 62, and the two annular pins 62 are located in the annular groove 6 and fastened by screws 63; such a sealing ring 37 is Hollow and easy to deform, the C-shaped ring pipe section 61 will be flattened after it contacts the cabinet body, forming a larger sealing surface, which can effectively improve the sealing performance, and at the same time, because of its hollow structure, it can effectively absorb vibration and reduce the transmission of vibration .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com