Automatic integrated production line for scratching and washing bacteria

A production line and automatic technology, which is applied in horticulture, agriculture, plant cultivation, etc., can solve the problems of easily polluting the working environment, affecting the growth of edible fungi, reducing the efficiency of scratching bacteria or washing work, so as to reduce waste, reduce exercise time, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

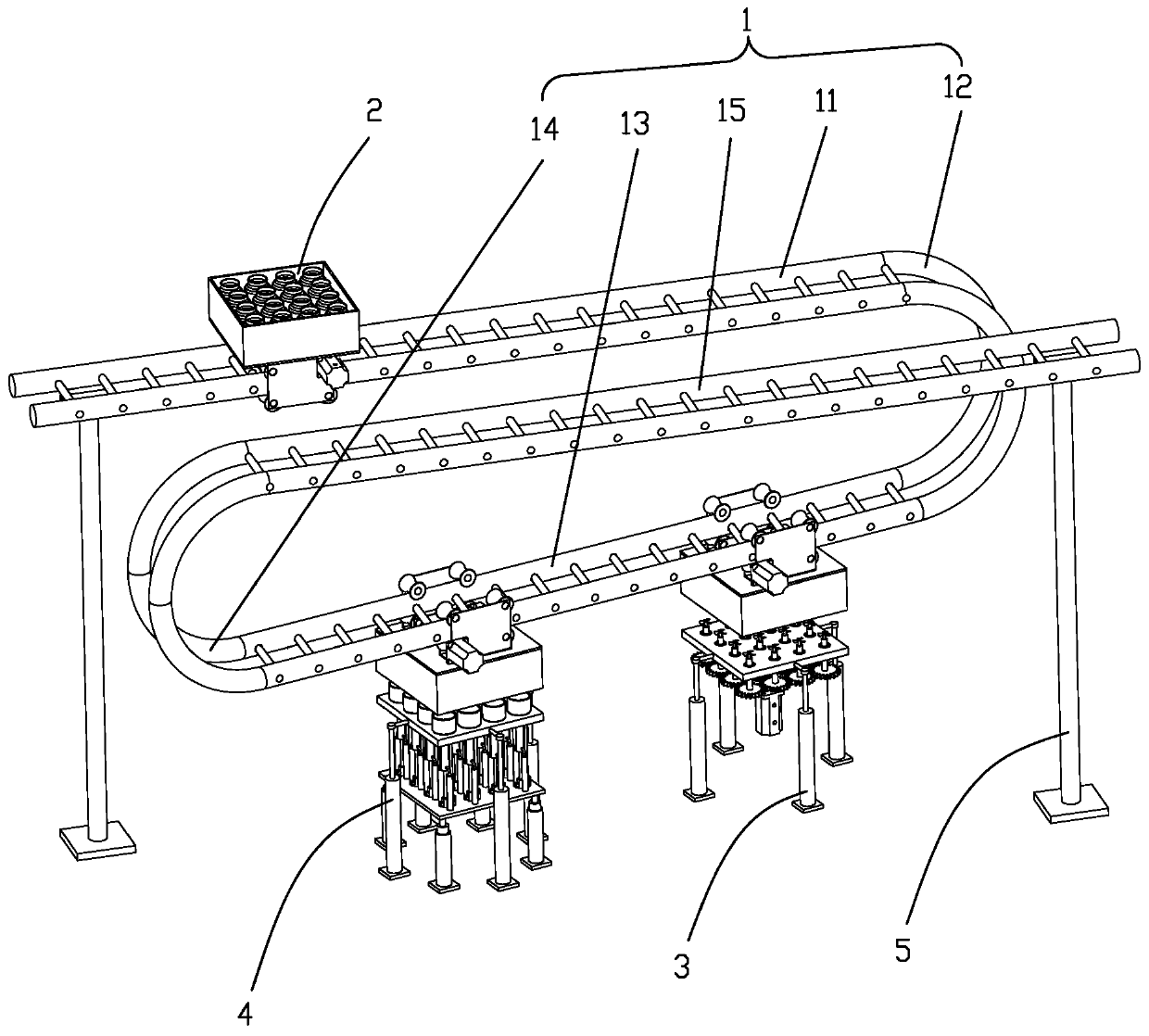

[0059] Such as Figure 1-11 As shown, the automatic integrated production line for scratching and washing bacteria includes an overturning track 1 , a loading and transporting device 2 , a bacteria scratching device 3 , a washing and capping device 4 and a supporting column 5 .

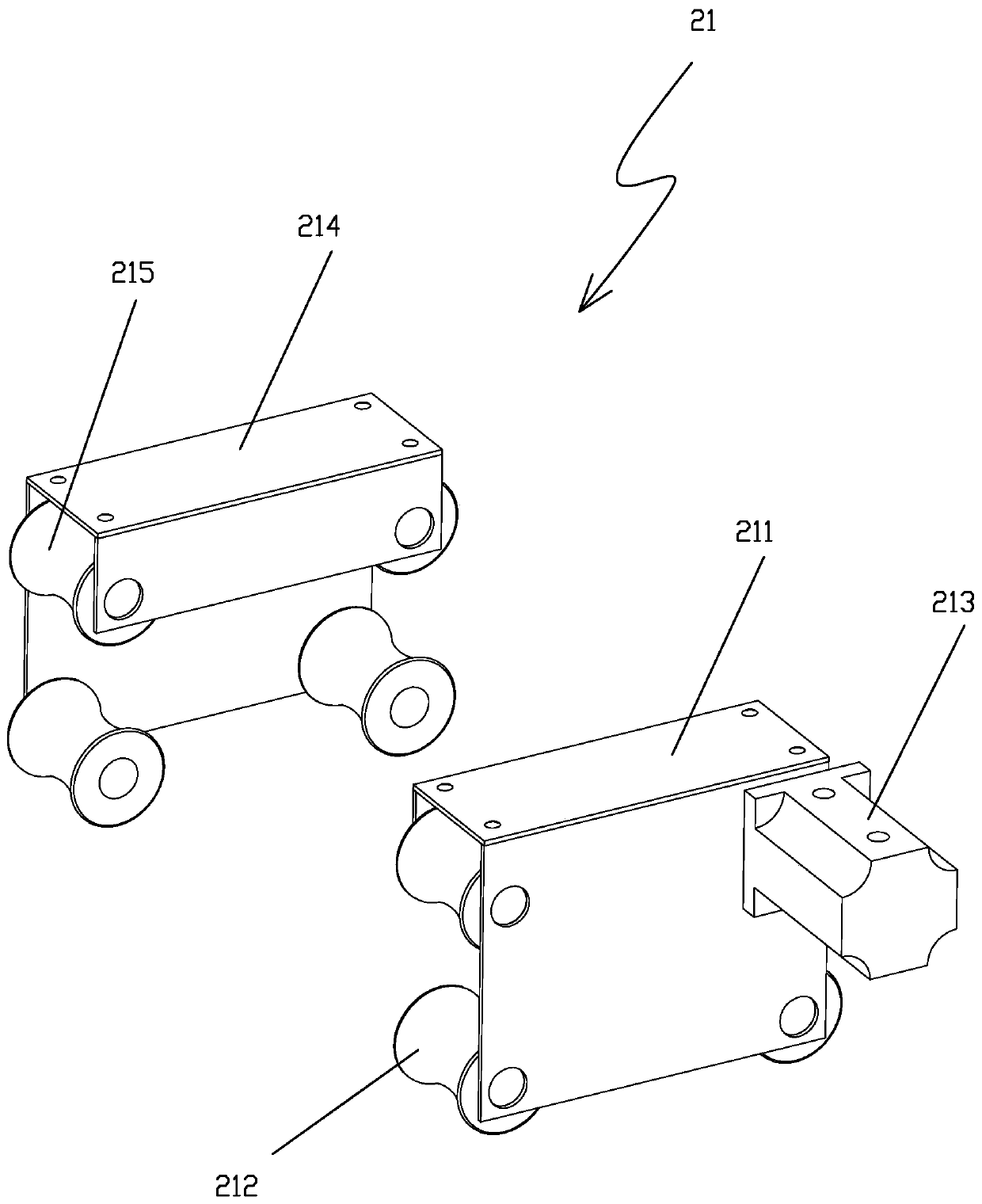

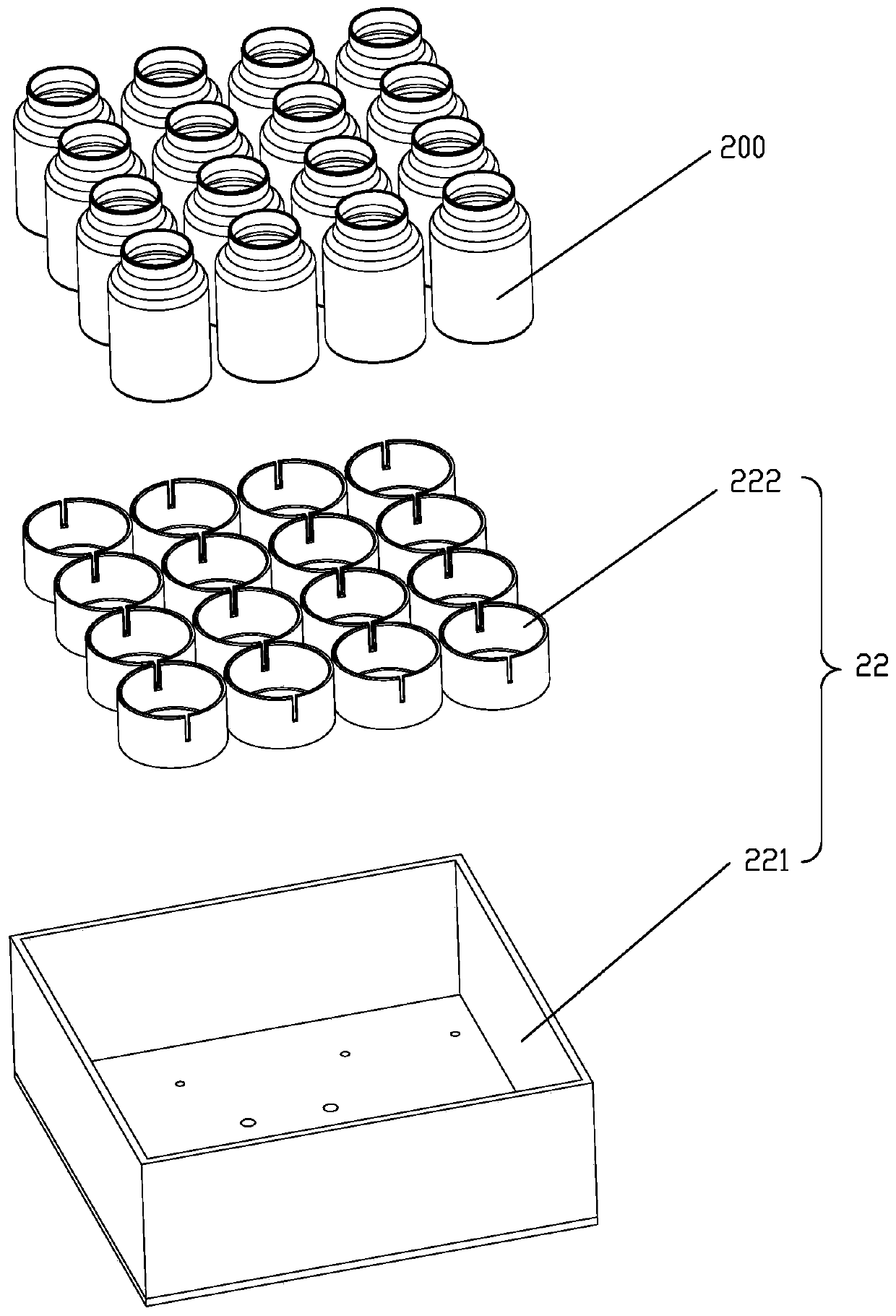

[0060] Specifically, the loading and transporting device 2 is arranged on the overturning track 1 for loading the edible fungus culture bottle 200, and can move along the overturning track 1 and realize overturning, so that the edible fungus culture bottle 200 passes through the mouth of the bottle. Flip from the upward state to the bottle mouth downward state. The fungus scratching device 3 is arranged below the overturning track 1, and when the loading and transporting device 2 moves above the fungus scratching device 4 and the edible fungus culture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com