Production process of scientific and technological veneering solid wood composite floorboard

A technology of solid wood composite flooring and production technology, which is applied in the jointing of wooden veneers, wood processing equipment, wood treatment, etc., and can solve the problem of surface scratch resistance, lack of wear resistance, high content of harmful volatiles in paint, and finishing processes To achieve the effect of strong three-dimensional sense, rich colors and rich visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0037] Example 2: Prepared melamine impregnated technical wood veneer solid wood composite floor

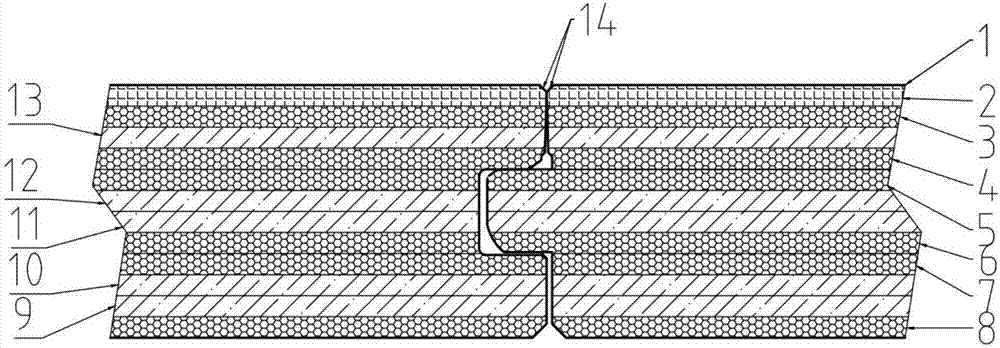

[0038] Such as figure 1 As shown, the obtained technical wood veneer solid wood composite floor is composed of substrate layer 3-13, technical wood skin layer 2, and aluminum oxide wear-resistant layer 1 from bottom to top, and the technical wood skin layer 2 is impregnated with melamine After treatment, it is hot-pressed with the wear-resistant layer 1 and the substrate layer 3-13. The floor surface has a concave-convex texture, and the longitudinal and transverse sides of the floor are respectively equipped with suitable tenons and grooves. The concave-convex texture can be hand scratch or saw marks.

[0039]The base layer is a multi-layer plywood made of fast-growing wood veneers of a certain thickness. More preferably, as figure 1 As shown, the multilayer plywood has an eleven-layer structure, wherein the first layer 3 and the eleventh layer 8 are birch veneers, the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com