Shaving board with low formaldehyde emission volume and preparation method of shaving board

A low formaldehyde release, particle board technology, applied in the field of particle board, can solve problems such as the difficulty of urea-formaldehyde resin, and achieve the effect of reducing the amount of formaldehyde and slowing the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

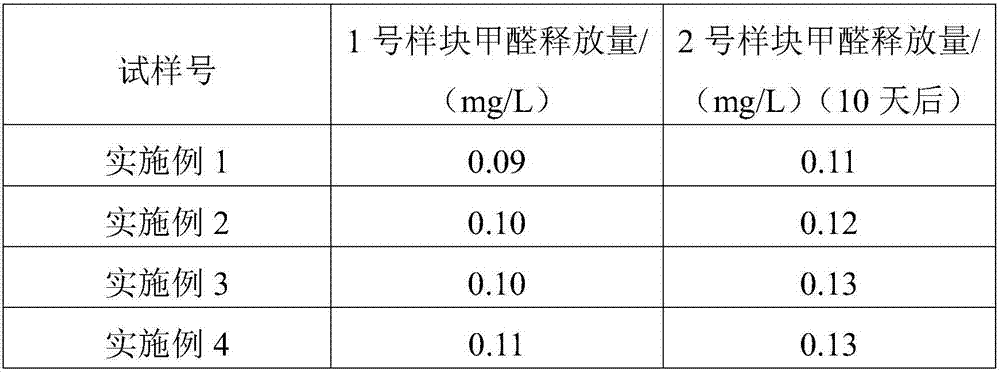

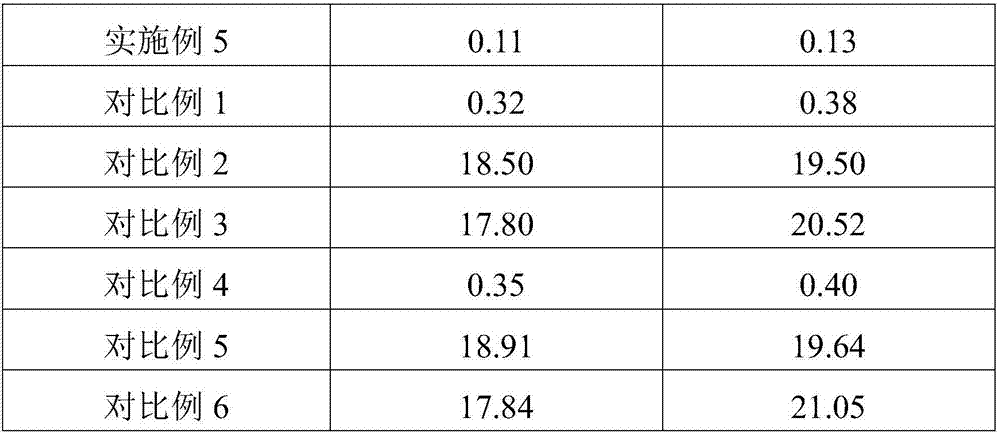

Examples

Embodiment 1

[0030] A kind of preparation method of the particle board of low formaldehyde emission:

[0031] (1) Carbonize the wood particle board raw material for 60 minutes under the condition of vacuum degree of 0.01Mpa and temperature of 250°C,

[0032] (2) Weigh the pretreated wood shavings in the step (1) of the formula amount, spray 4g coupling agent, 5g paraffin emulsion and 1g polyvinyl alcohol on the wood shavings, stir evenly, and then mix with 15g glue agent to obtain a premix;

[0033] (3) Lay the premix in step (2) into the mold. The thickness of the premix laying is 35.8cm, apply a pressure of 300Pa to pre-press for 9min, then raise the temperature to 250°C, and press it under a pressure of 1000Pa 50min, get 17.9mm thick core board;

[0034] (4) Leave the core board of step (3) for 5 hours, then use a punching machine to punch out air holes on the core board, the aperture of the air holes is 2mm, and the distance between adjacent air holes is 8mm, and then Stack the core...

Embodiment 2

[0037] A kind of preparation method of the particle board of low formaldehyde emission:

[0038] (1) Carbonize the wood particle board raw material for 50 minutes under the condition of vacuum degree of 0.015Mpa and temperature of 240°C,

[0039](2) Take the pretreated wood shavings in the step (1) of the formula amount, spray 2g coupling agent, 4g paraffin wax emulsion and 0.5g polyvinyl alcohol on the wood shavings, stir evenly, and then mix with 8g glue Sticky agent, obtain premix;

[0040] (3) Lay the premix in step (2) into the mold. The thickness of the premix laying is 45.4cm, apply a pressure of 150Pa to pre-press for 8min, then raise the temperature to 240°C, and press it under a pressure of 1000Pa 40min, obtain the core layer plate that thickness is 22.7mm;

[0041] (4) Leave the core board of step (3) for 1 hour, then use a punching machine to punch out vent holes on the core board, the diameter of the vent hole is 1mm, and the distance between adjacent vent holes...

Embodiment 3

[0044] A kind of preparation method of the particle board of low formaldehyde emission:

[0045] (1) Carbonize the wood particle board raw material for 60 minutes under the condition of vacuum degree of 0.28Mpa and temperature of 270°C,

[0046] (2) Take the pretreated wood shavings in the step (1) of the formula amount, spray 5g coupling agent, 6g paraffin wax emulsion and 1.2g polyvinyl alcohol on the wood shavings, stir evenly, and then mix with 16g glue Sticky agent, obtain premix;

[0047] (3) Lay the premix in step (2) into the mold. The thickness of the premix laying is 73.4cm, apply a pressure of 500Pa to pre-press for 9min, then raise the temperature to 270°C, and press it under a pressure of 1300Pa 50min to obtain a core plate with a thickness of 36.7mm;

[0048] (4) Leave the core board of step (3) for 2 hours, then use a punching machine to punch out air holes on the core board, the aperture of the air holes is 2mm, and the distance between adjacent air holes is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com