A processing technology of cotton fiber and metal wire blended yarn

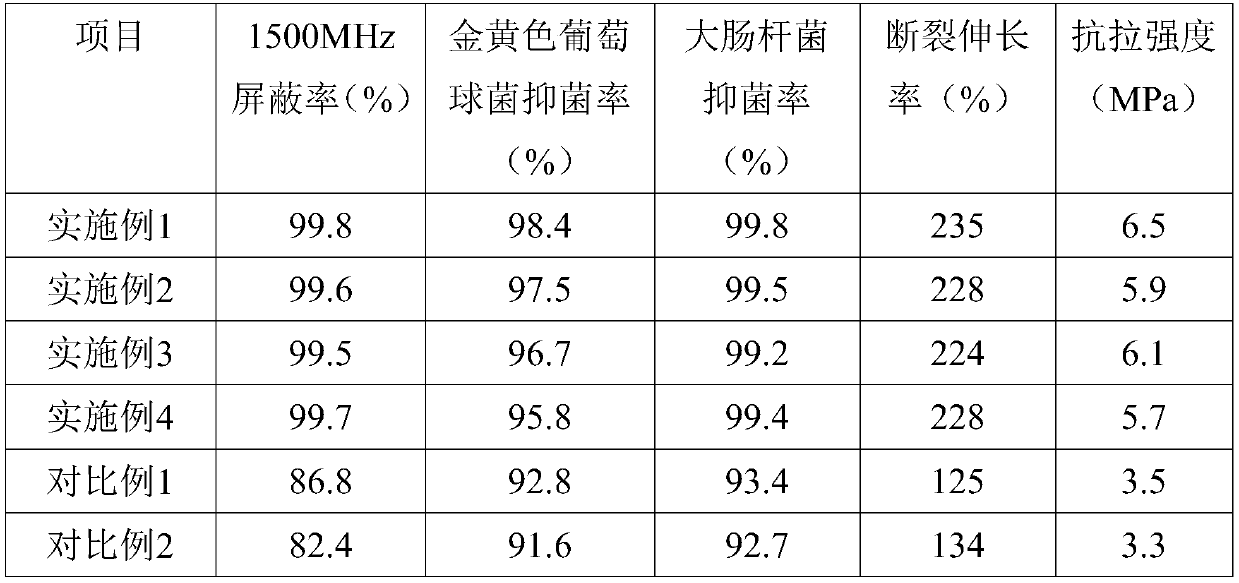

A technology of blended yarn and processing technology, which is applied in the field of processing technology of cotton fiber and metal wire blended yarn, can solve the problems of uneven yarn dryness, high production cost, poor anti-pilling and fuzzing performance, etc., and achieve beautiful Effects of metallic luster, excellent mechanical properties, and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A processing technology of cotton fiber and metal wire blended yarn, comprising the following steps:

[0024] (1) Metal wire preparation: Pre-crushing stainless steel powder to 100-200 mesh, adding it to a planetary ball mill tank, adding ethanol with 6 times the mass of stainless steel powder, and adding 20-30 mm in size according to the ball-to-material ratio of 42:1. Grinding balls, heating up to 40°C, milling at a speed of 480r / min for 15 hours; after cooling to room temperature, mix copper powder, zinc powder, cobalt powder, nickel powder, and graphite powder in a mass ratio of 3:1:1:1 : 0.2 was added into the ball mill jar, and ground at room temperature and at a speed of 250r / min for 20 hours to obtain a mixture; the mixture was washed with ethanol for 3 times, concentrated under reduced pressure to remove ethanol to obtain a dry material; the dry material was hot-pressed and sintered at 1365°C to obtain an alloy ; The alloy is obtained by a single wire drawing m...

Embodiment 2

[0029] A processing technology of cotton fiber and metal wire blended yarn, comprising the following steps:

[0030] (1) Metal wire preparation: Pre-crushing stainless steel powder to 100-200 mesh, adding it to a planetary ball mill tank, adding ethanol with 8 times the mass of stainless steel powder, and adding 20-30 mm in size according to the ball-to-material ratio of 46:1. Grinding balls, heating up to 42°C, ball milling at a speed of 500r / min for 14 hours; after cooling to room temperature, mix copper powder, zinc powder, cobalt powder, nickel powder, and graphite powder in a mass ratio of 3:1:1:1 : 0.2 was added to the ball mill tank, and ground at room temperature and at a speed of 300r / min for 21 hours to obtain a mixture; the mixture was rinsed with ethanol for 5 times, concentrated under reduced pressure to remove ethanol to obtain a dry material; the dry material was hot-pressed and sintered at 1400°C to obtain an alloy ; The alloy is obtained by a single wire drawi...

Embodiment 3

[0035] A processing technology of cotton fiber and metal wire blended yarn, comprising the following steps:

[0036] (1) Metal wire preparation: Pre-crushing stainless steel powder to 100-200 mesh, adding it to a planetary ball mill tank, adding ethanol with 6 times the mass of stainless steel powder, and adding 20-30 mm in size according to the ball-to-material ratio of 50:1. Grinding balls, heating up to 45°C, ball milling at a speed of 600r / min for 15 hours; after cooling to room temperature, mix copper powder, zinc powder, cobalt powder, nickel powder, and graphite powder in a mass ratio of 3:1:1:1 :0.2 was added to the ball mill jar, and ground at room temperature and at a speed of 300r / min for 20 hours to obtain a mixture; the mixture was rinsed with ethanol for 4 times, concentrated under reduced pressure to remove ethanol to obtain a dry material; the dry material was hot-pressed and sintered at 1450°C to obtain an alloy ; The alloy is obtained by a single wire drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com