Maritime work admixture

A technology of admixtures and marine engineering, applied in the field of marine engineering admixtures, can solve the problems of poor durability, poor construction quality, and harsh construction environment in marine engineering, and achieve the goals of improving work performance, improving anti-corrosion ability, and reducing cement consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In parts by weight, the specific surface area is 420m 2 / kg S95 grade slag powder 60 parts, fly ash 35 parts, desulfurization gypsum 5 parts.

Embodiment 2

[0033] In parts by weight, the specific surface area is 420m 2 / kg S95 grade slag fine powder 65 parts, fly ash 32 parts, sodium sulfate 3 parts.

Embodiment 3

[0035] In parts by weight, the specific surface area is 420m 2 / kg S95 grade slag powder 70 parts, fly ash 22 parts, desulfurization gypsum 5 parts, sodium sulfate 3 parts.

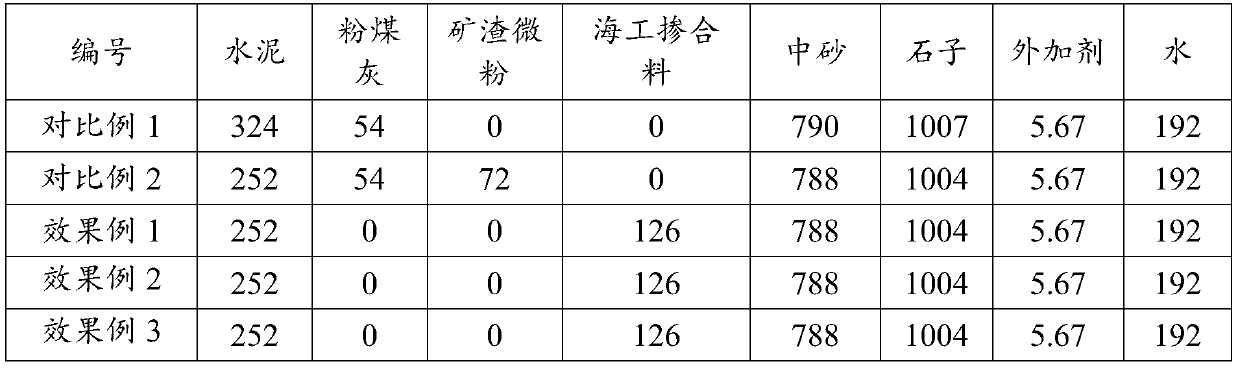

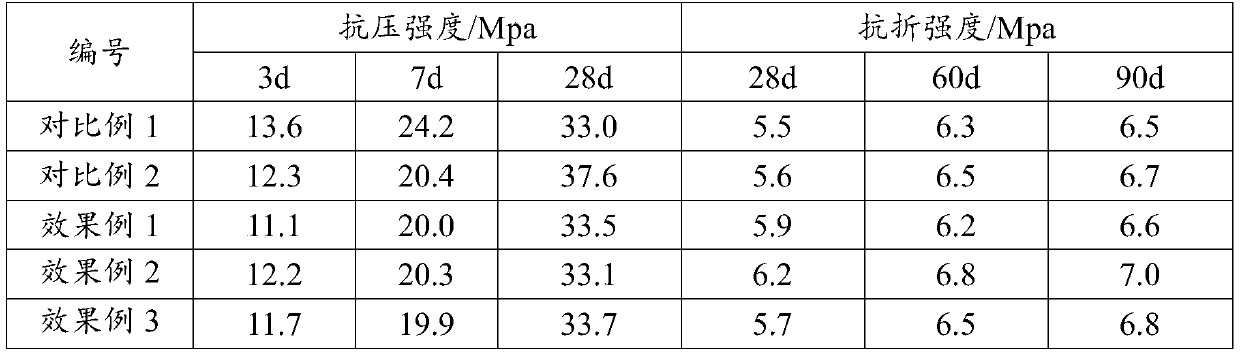

[0036] Test Data

[0037] The concrete test was carried out with the configured marine admixture. The concrete design was C30 grade, and the mix ratio was selected from the commonly used pumped concrete mix ratio. The water consumption was basically unchanged. The concrete slump was controlled to be 180±30mm by adjusting the amount of admixture. The mix ratio of C30 grade concrete is shown in Table 1, where:

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com