Fast cooling device for steam turbine

A rapid cooling, steam turbine technology, applied in mechanical equipment, engine components, engine functions, etc., can solve problems such as affecting the service life of steam turbines, long warm-up time periods, and potential safety hazards, achieving obvious practical significance and economic benefits, alleviating power The contradiction between supply and demand, the effect of preventing moisture corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

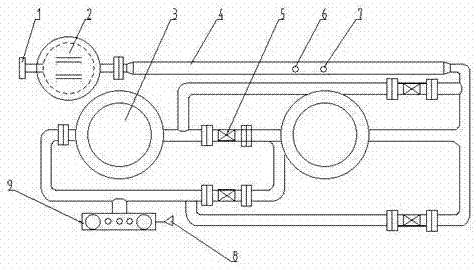

[0012] Such as figure 1 As shown, a rapid cooling device for a steam turbine is mainly composed of an air inlet flange 1, an oil-water filter 2, an air heater 3, a pipeline 4, a stop valve 5, a pressure gauge 6, a flow meter 7, a temperature measuring element 8 and a set The air box 9 is composed of an air inlet flange 1 on the left side of the oil-water filter 2, a connecting pipeline 4 on the right side of the oil-water filter 2, a pressure gauge 6 on the right side pipeline 4 of the oil-water filter 2, and a pressure gauge 6 There is a flow meter 7 on the right side, and an air heater is installed on the lower right side of the oil-water filter 2. 3. The two sides of the air heater 3 are connected to the pipeline 4. The right side of the air heater 3 is equipped with a stop valve 5 on the pipeline 1. The pipeline 1 below the device 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com