Waste incineration ash slag cooling system

A waste incineration ash and slag cooling technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of low air cooling efficiency and unfavorable slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

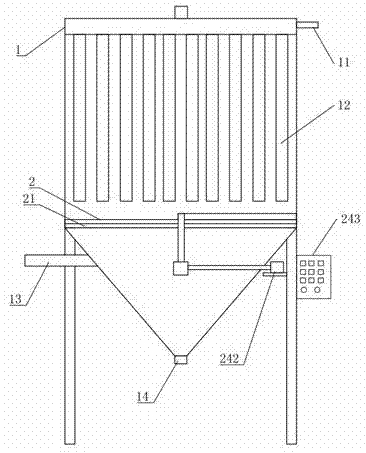

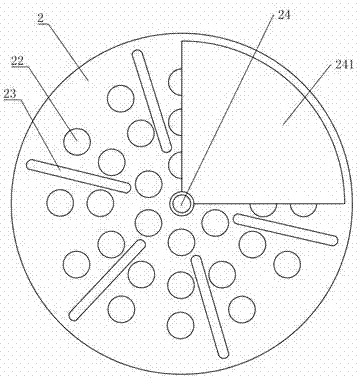

[0018] A waste incineration ash cooling system, such as figure 1 , 2 As shown, it includes a housing 1, the upper part of the housing 1 is cylindrical, and the lower part is conical. A cooling chassis 2 is arranged at the bottom of the housing 1, and the cooling chassis 2 is provided with a blanking opening 21 along its radial direction. The slagging outlet 13 arranged on the furnace body.

[0019] The bottom of the cooling coil 231 is provided with a spiral groove 23, and the groove 23 is embedded with a cooling coil 231. At the position of the blanking trough 22, the cooling coil 231 is bent to bypass the interfering blanking trough. 22. The bottom of the cooling chassis 2 is provided with an insulating foam board for insulating the cooling coil 231; the water inlet end of the cooling coil 231 is connected to the circulating water pump 24, the water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com