Control system and control method of rotating speed of inba drum

A technology for regulating the system and speed, applied in the direction of control system, motor control, process efficiency improvement, etc., can solve the problem of not finding a reasonable regulation of the speed of the INBA drum, and achieve the goal of reducing the difficulty of control, avoiding damage, and prolonging the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment this patent is described further:

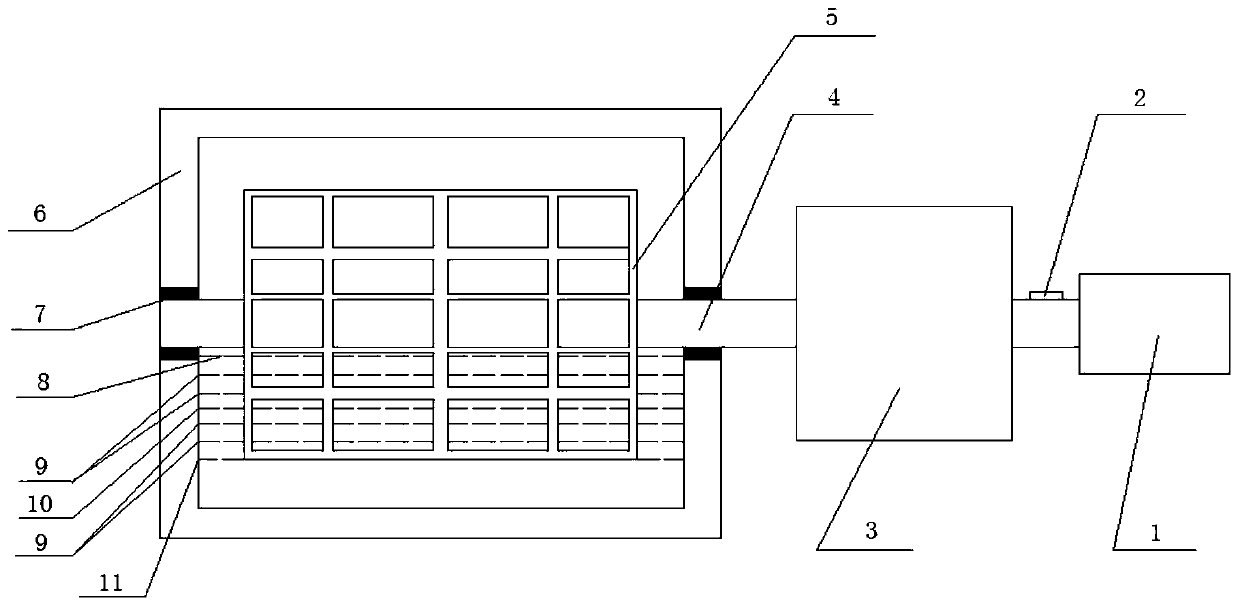

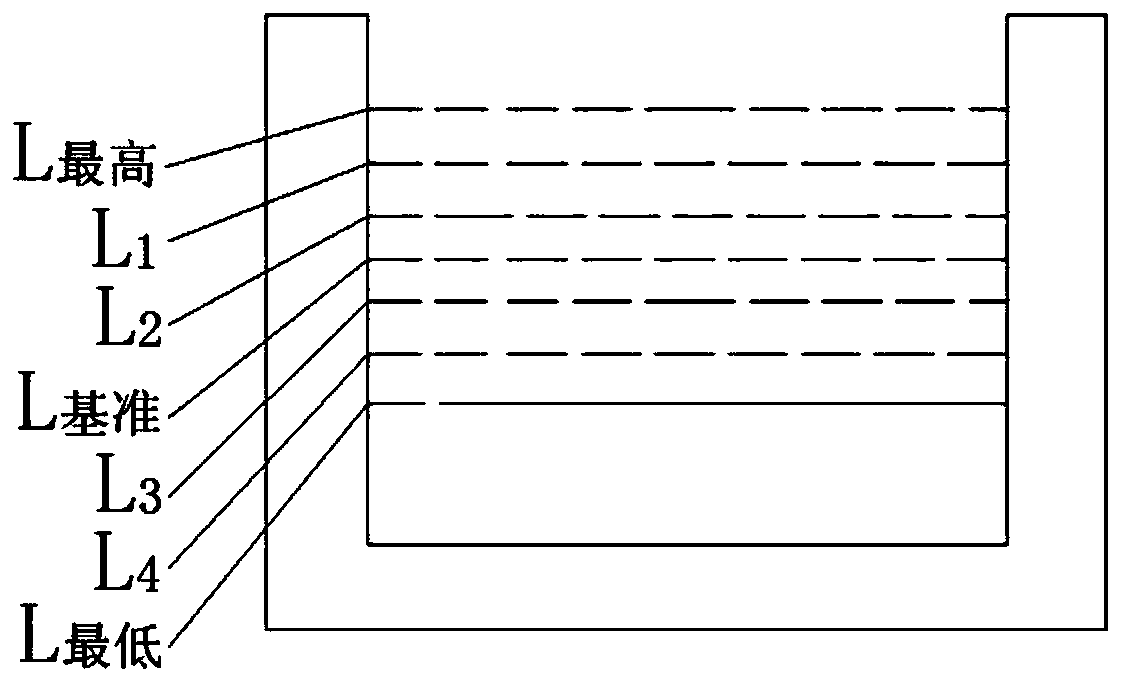

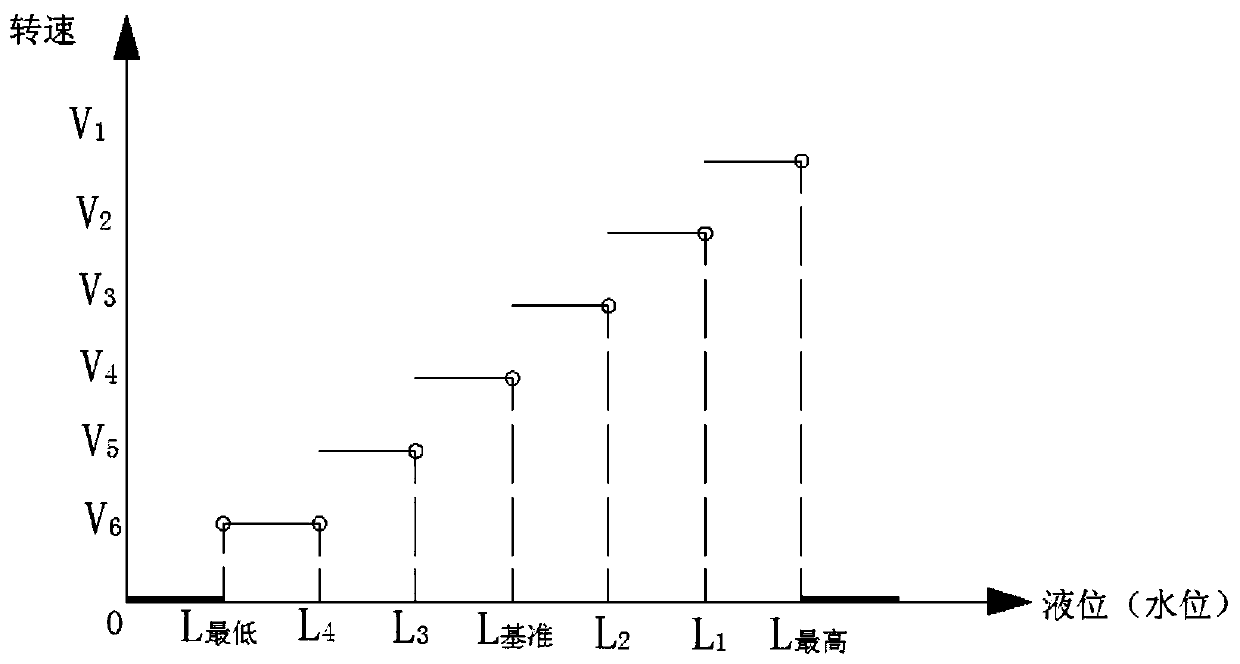

[0037] as attached figure 1 As shown, a control system for the rotating speed of an INBA drum includes a motor 1, the motor is connected with a transmission shaft 4 and a bearing 7 through a reducer 3, a drum 5 is installed on the transmission shaft 4 and the bearing 7, and the drum is located in a cooling pool 6 Inside, a torque meter 2 is installed on the motor, which is mainly used to measure the torque of the motor in real time; in the cooling pool, there is cooling water, and multiple water levels are designed in the cooling pool, including the highest water level 8, the reference water level 10 and The lowest water level line 11, between the highest water level line and the lowest water level line, is provided with a plurality of scale water level lines 9, and the scale water level lines are evenly distributed on both sides of the reference water level line, and a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com