Welding workpiece cooling air conditioner

A workpiece and air-conditioning technology, which is applied in air-conditioning systems, welding equipment, laser welding equipment, etc., can solve the problems of prolonging the production period of workpieces, long cooling time, and affecting the performance of workpieces, so as to shorten the cooling time and ensure the quality of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

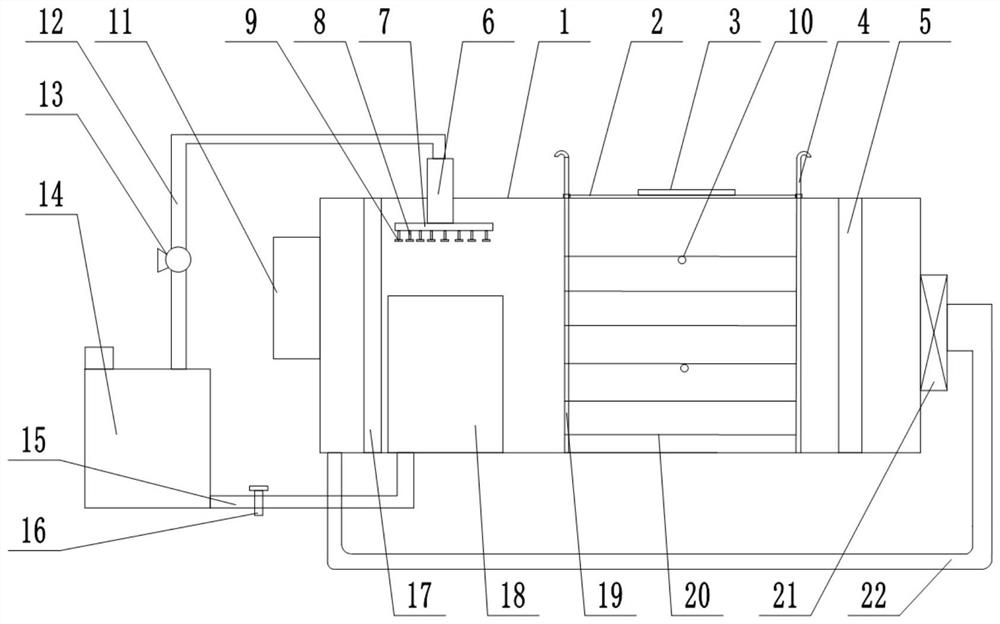

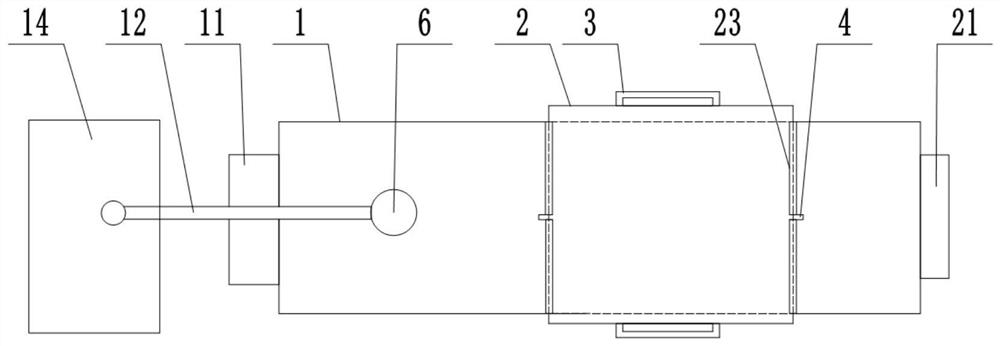

[0016] An air conditioner for cooling welding workpieces, comprising a chassis 1, a water tank 14 and a fan 21, two ends of the chassis 1 are respectively provided with an air inlet 11 and an air outlet, and the end of the inner wall of the chassis 1 near the air inlet 11 is provided with a front filter 17, and the front filter 17 A water collecting tank 18 is placed at the rear of the cabinet 1. The top of the cabinet 1 is facing the water collecting tank 18 and a spray device is installed. The water pipe 15 and the water outlet pipe 15 are connected to the water tank 14, the water outlet pipe 15 is provided with a throttling valve 16, the middle of the top of the cabinet 1 is provided with a workpiece port, and the workpiece port is equipped with a sliding door 2 that slides to both sides, and the cabinet 1 A display rack 19 is arranged at the corresponding workpiece opening in the interior, and a temperature sensor 10 is arranged on the display rack 19. The rear filter scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com