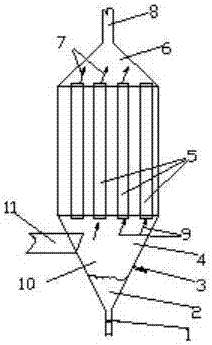

Air bottom-in and top-out cooler

A technology of air coolers and tube coolers, applied in the field of bottom-in and top-out air coolers, can solve problems affecting the smelting operation environment, increase ventilation resistance, increase power consumption, etc., prevent dust from blocking tube problems, reduce The effect of small fan power and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1) Dust-containing tail gas coolers such as submerged arc furnaces or submerged electric furnaces use bottom-inlet and top-outlet coolers, and the number, diameter, cross-section and length of the cooling tubes (5) and the spacing between the tubes are designed according to the temperature and air volume of the smelting tail gas .

[0012] 2) Bottom air inlet chamber (4) is installed at the bottom of the bottom of the bottom air inlet chamber (4), and dust sedimentation chamber (10) and ash discharge valve (1) are arranged at the bottom of the bottom air inlet chamber (4). The specific size and shape are according to the design requirements , Dust volume and air cooling requirements are determined.

[0013] 3) The top of the cooler with bottom inlet and top outlet is provided with a top outlet bin (6), and the outlet bin is connected to the main outlet pipe (8).

[0014] 4) Choose natural cooling or fan frequency conversion air cooling according to air cooling requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com