Gravity casting simulation test stand

A simulation test bench, gravity casting technology, which is used in testing metals, teaching models, foundry workshops, etc., can solve the problem of not meeting the needs of gravity casting simulation tests for casting molding, lack of indoor gravity casting simulation test devices, and inability to perform casting law simulation tests. and other problems, to achieve the effect of compact structure, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

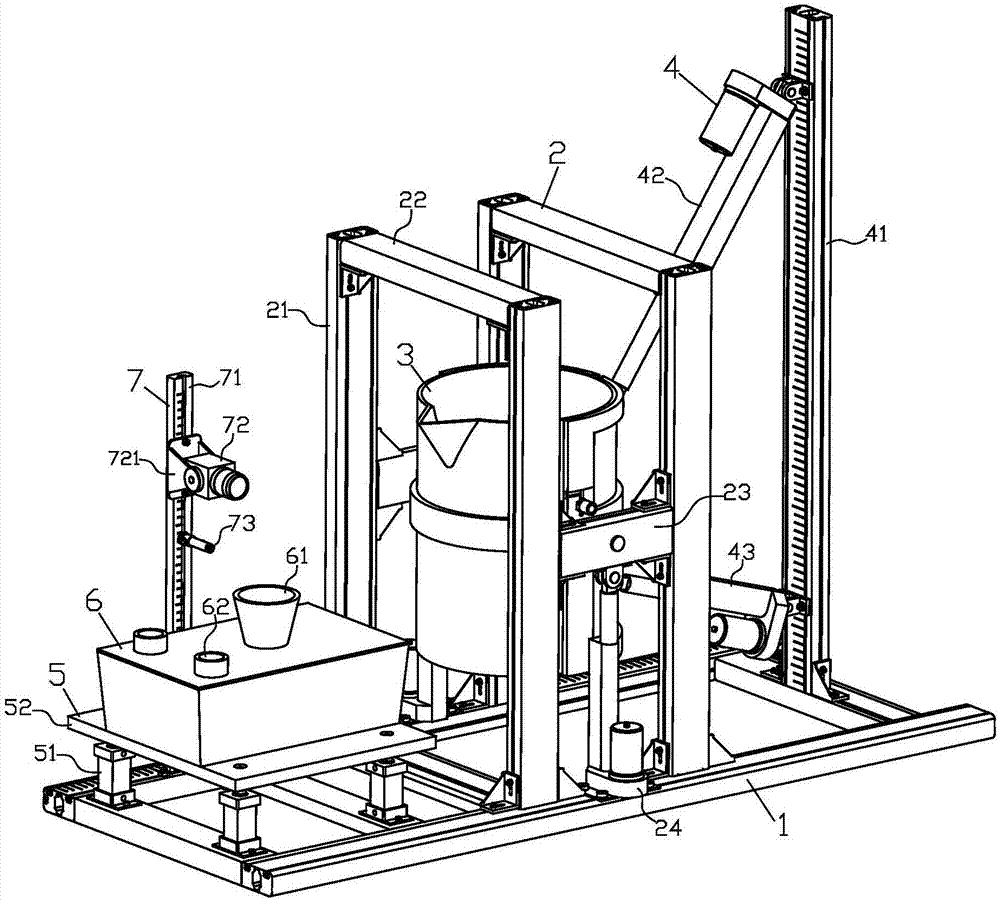

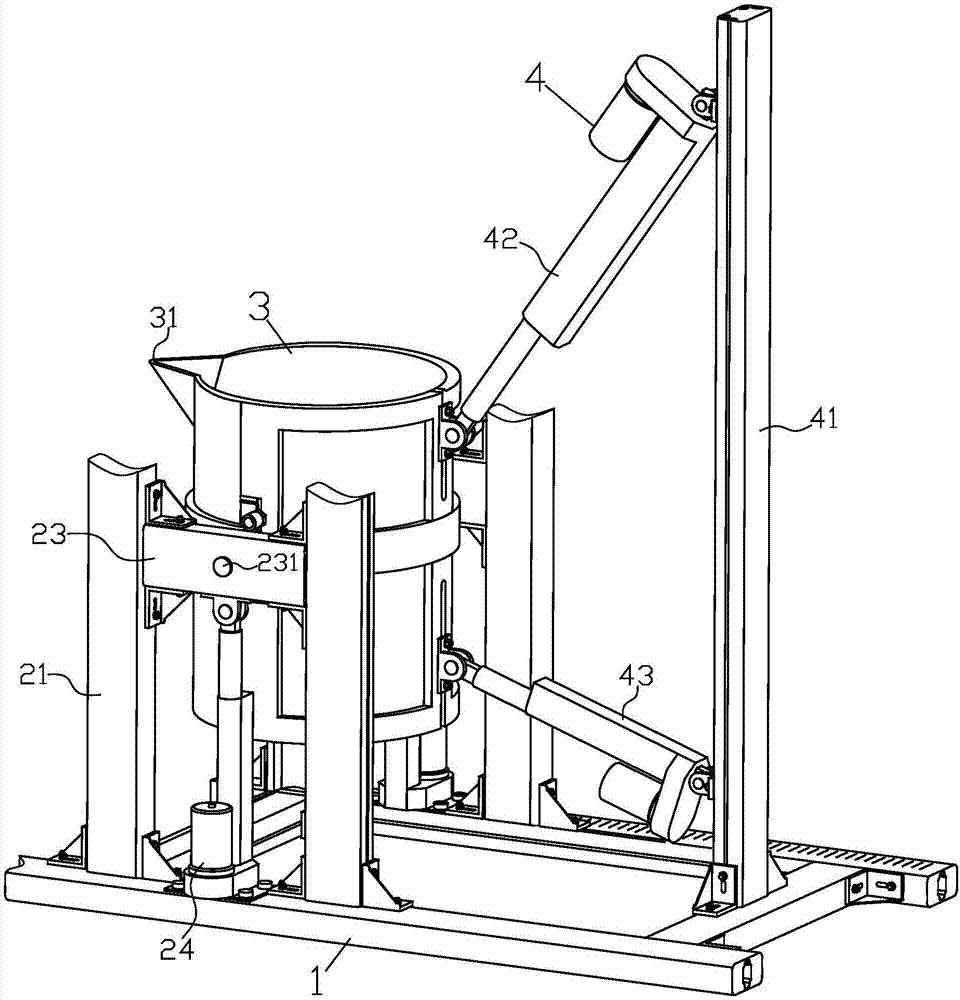

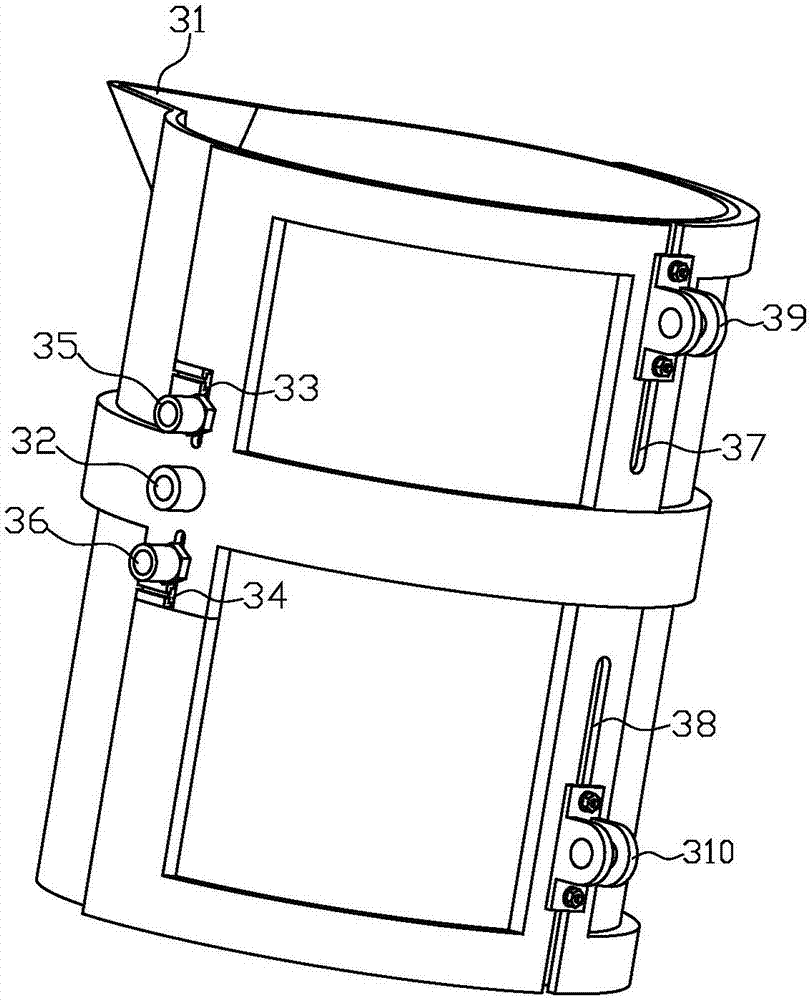

[0025] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a gravity casting simulation test bench includes a base 1 , a ladle frame 2 , a test ladle 3 , a pouring device 4 , a vibrating table 5 , a simulation sand box 6 and a measuring device 7 . Wherein, the ladle frame 2 is located in the middle of the base 1, and is fixedly connected with the base 1 by screws; the test ladle 3 is installed on the ladle frame 2, and both sides of the test ladle 3 are connected to the ladle The frame 2 is connected by a hinge; the pouring device 4 is located at the rear of the base 1, the bottom of the pouring device 4 is fixed on the base 1 by screws, and the front end of the pouring device 4 passes through the test ladle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com