Die-casting die-spotting safety production visualized monitoring system and method

A safety production and monitoring system technology, applied in general control systems, control/adjustment systems, simulators, etc., can solve the problems of not being able to know whether there are people in the die-casting equipment in real time, hidden safety hazards, etc., to improve supervision and control capabilities and ensure safety The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below with reference to the accompanying drawings.

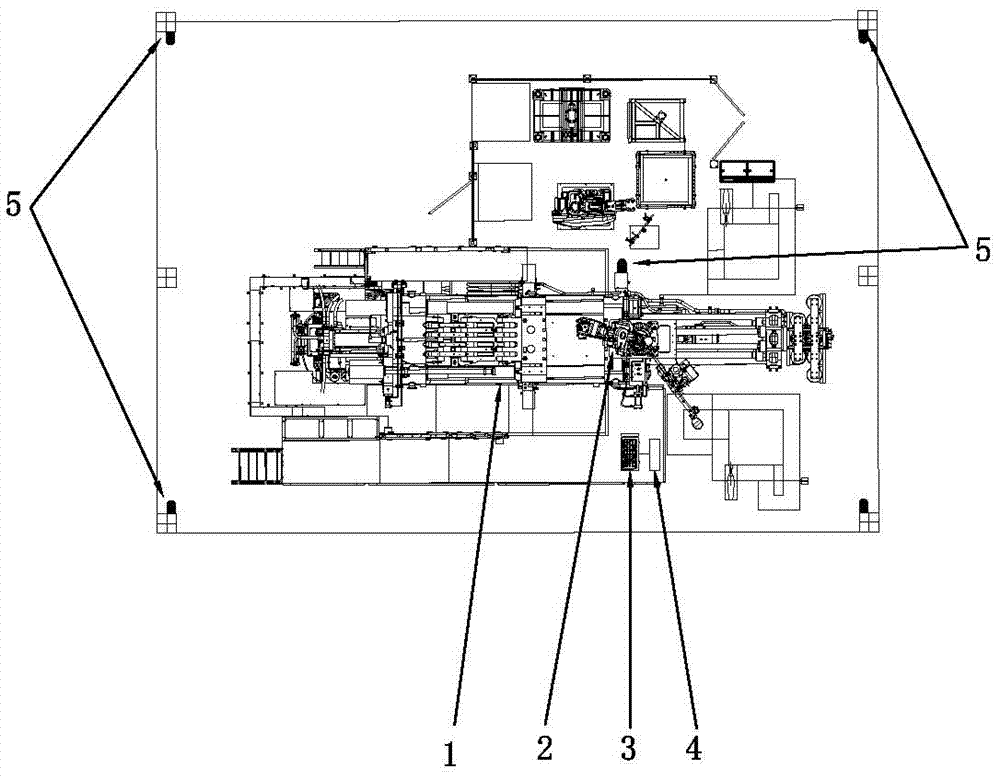

[0020] In view of the increasing volume of existing die-casting equipment, in general, workers cannot see the other side from one side of the equipment. If there are other personnel who are close to the mold during the production process In order to solve this monitoring problem, there will be hidden dangers in production safety. The present invention provides a visual monitoring system for die-casting mold clamping safety production, including a die-casting device 1, a mold monitor (not shown in the drawings), an operation robot 2, a communication cable, a central control machine 3 and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com