Unit motor modular consequent pole permanent magnet synchronous linear motor

A permanent magnet synchronous linear and motor module technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of continuous pole permanent magnet synchronous linear motor thrust fluctuation, etc., to suppress end effects, reduce volume and mass, The effect of increasing thrust density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

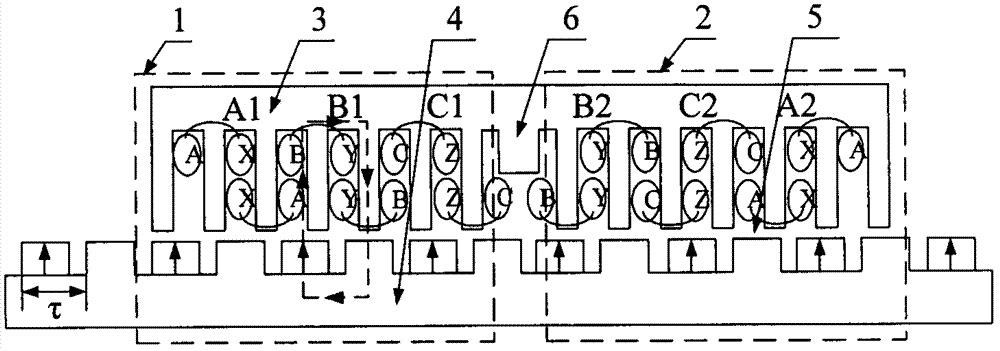

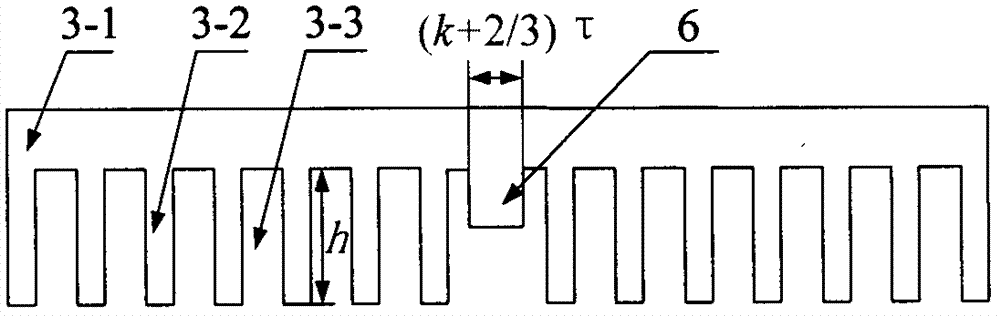

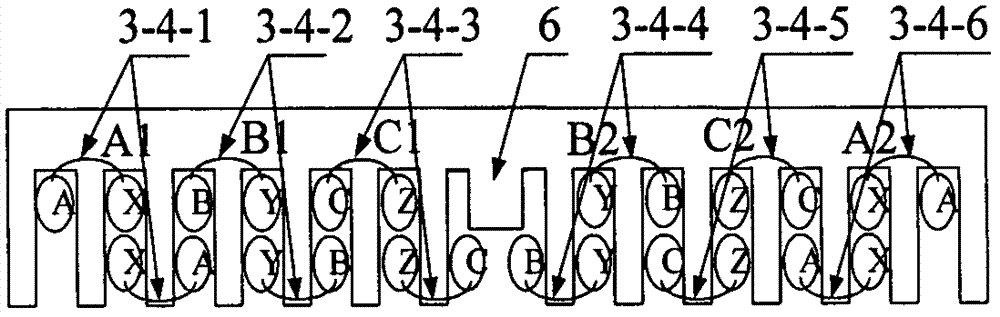

[0022] Such as figure 1 , 2, 3, 4, 5, the unit motor modular continuous pole permanent magnet synchronous linear motor includes unit motor one 1 and unit motor two 2, and each unit motor includes a primary assembly 3 and a secondary assembly 4. The primary assembly 3 consists of a primary yoke 3-1, a primary tooth 3-2 and an armature winding 3-4, which is arranged in the slot 3-3. The secondary assembly 4 is composed of permanent magnets 4-1, iron poles 4-2 and secondary yokes 4-3, the permanent magnets and iron poles are arranged alternately, and the magnetization direction of all permanent magnets is the same. An air gap 5 exists between the primary assembly 3 and the secondary assembly 4 . Between the unit motor one 1 and the unit motor two 2, a magnetic modulation structure 6 is arranged. The magnetic modulation structure 6 is made of a magnetic permeable material, and is integrally formed with the primary yoke 3-1. On the magnetic adjustment structure 6, the width of th...

Embodiment approach 2

[0026] Such as Image 6 As shown, the motor adopts three unit motor structures, a magnetic modulation structure 10 is arranged between the first unit motor 7 and a second unit motor 8, and a magnetic modulation structure 11 is arranged between the second unit motor 8 and the third unit motor 9. The phase sequence of the windings on unit motor one 7 is arranged in accordance with phase A winding-phase B winding-phase C winding. The upper windings of unit motor 2 8 are set according to B-phase winding-C-phase winding-A-phase winding. The upper winding of unit motor three 9 is according to C phase winding-A phase winding-B phase winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com