Negative ion quilt and manufacturing method thereof

A manufacturing method and technology of negative ions, which can be applied to home appliances, bedspreads, applications, etc., can solve the problems of easy breeding of bacteria and mites, affecting the comfort of quilts, and detrimental to human health, so as to benefit human health, inhibit the breeding of insects and mites, and prevent hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

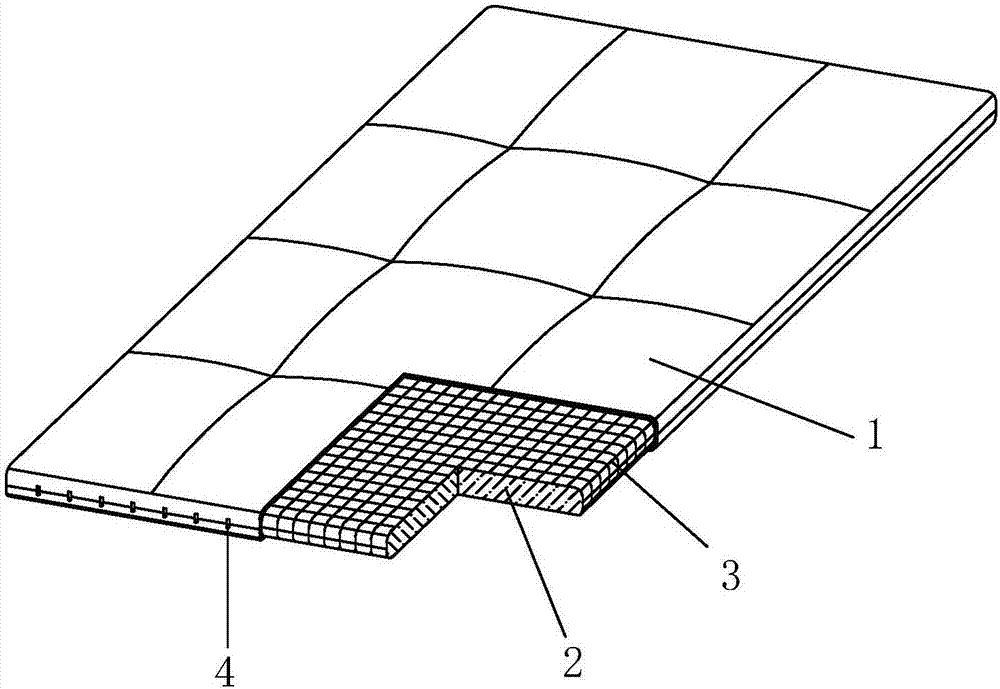

[0041] A kind of negative ion blanket, refer to figure 1 , which includes a quilt cover 1, the quilt cover 1 is made of two layers of pure cotton fabrics. The three sides of the quilt cover 1 are fixed by sewing, and an opening for the quilt core 2 is left on the other side. The side with the opening is provided with a detachable component 4, and the detachable component 4 can be selected from snap buttons or Velcro. In this embodiment, the detachable component 4 is a snap button, and the opening of the quilt cover 1 can be closed through the cooperation of the sub-button and the female button, which facilitates the removal and washing of the quilt cover 1 .

[0042] refer to figure 1 , the quilt cover 1 is filled with a quilt core 2, and the quilt core 2 is covered with a net cover 3 woven by polyester thread. The mesh number of the net cover 3 can be selected in many ways, but it should not be too low, preferably 10-35 mesh .

[0043] refer to figure 1 , the various fib...

manufacture Embodiment 1

[0045] A kind of method for manufacturing negative ion quilt in embodiment 1, comprises the steps:

[0046] a is prepared by core 2

[0047] Calculate the amount of negative ion finishing agent according to the amount of fiber to be modified, weigh the negative ion finishing agent with the standard of 3.5% o.w.f, add water according to the bath ratio of 1:15, and prepare the negative ion finishing solution.

[0048] The polyester fibers and acrylic fibers to be treated are completely immersed in the negative ion finishing solution, heated and stirred to make the fibers fully contact with the treatment solution. Maintain the temperature of the treatment liquid at 45-50°C, take out the fibers after 45 minutes of treatment, wash them with cold water, and dry them in the air to prepare anion-modified polyester fibers and anion-modified acrylic fibers for future use. It can be treated with long filament fibers of polyester fiber and acrylic fiber, and then cut into short fibers of...

Embodiment 3

[0054] A method for manufacturing the negative ion quilt in Example 1, which is basically the same as in Example 2, the only difference being that the detachable component 4 is a Velcro button, and the sub-button and the female button of the Velcro are respectively sewn on the two-layer quilt cover 1 on the fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com