Graded type dual-hole-diameter sieve plate tower

A double-aperture, sieve-tray tower technology, applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, can solve problems such as hindering the large-scale application of sieve-tray towers, reducing gas absorption efficiency, and eliminating the pulse phenomenon. , The effect of improving the efficiency of the board and prolonging the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

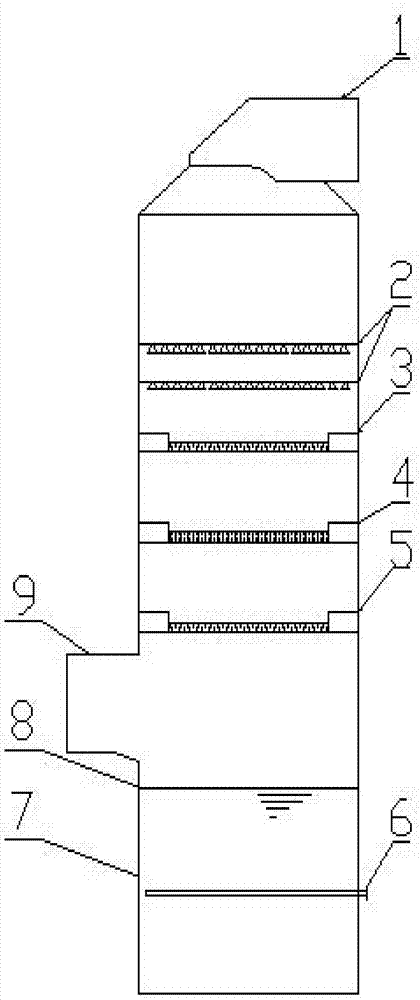

[0033] The present invention's hierarchical double-aperture sieve tray tower, as attached figure 1 As shown, the tower body 7 comprising a hollow cylindrical structure, the upper part of the tower body is a spray layer 2, and the lower part is a slurry tank 8, and a flue gas inlet 9 is arranged on the tower body between the slurry tank 8 and the spray layer 2, and the tower body The uppermost end of the body 7 is provided with a flue gas outlet 1; the tower body between the flue gas inlet 9 and the spray layer 2 is provided with two or more horizontally arranged sieve plates (3, 4, 5). There are gas through-holes that can only pass through high-speed flue gas and liquid through-holes that can only pass through falling droplets; the slurry tank 8 is also equipped with a stirring pump 6 .

[0034] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com