Optimal design method for lowering omission factor of bundling machine gatherer

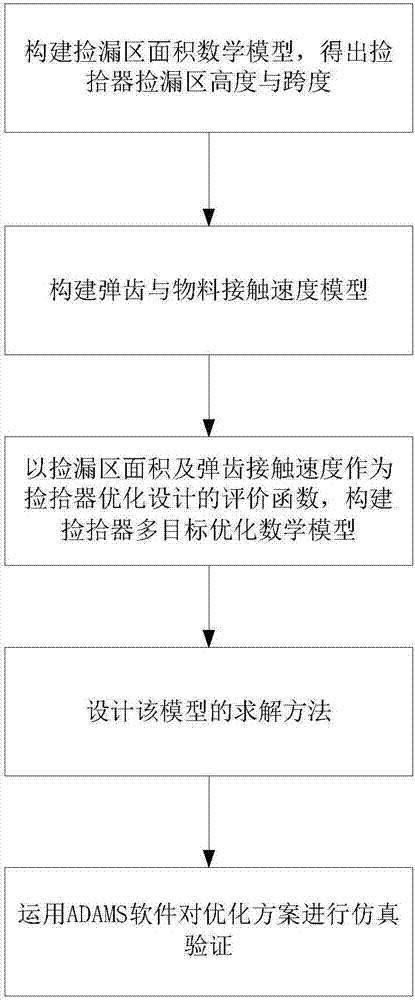

A technology for optimizing design and pickers, which is applied in multi-objective optimization, design optimization/simulation, instruments, etc., and can solve the problems that the picker cannot pick up accurately, the pick-up rate is not high, and the area of the pick-up area is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific embodiments and accompanying drawings, but the content of the present invention is not limited to the following embodiments.

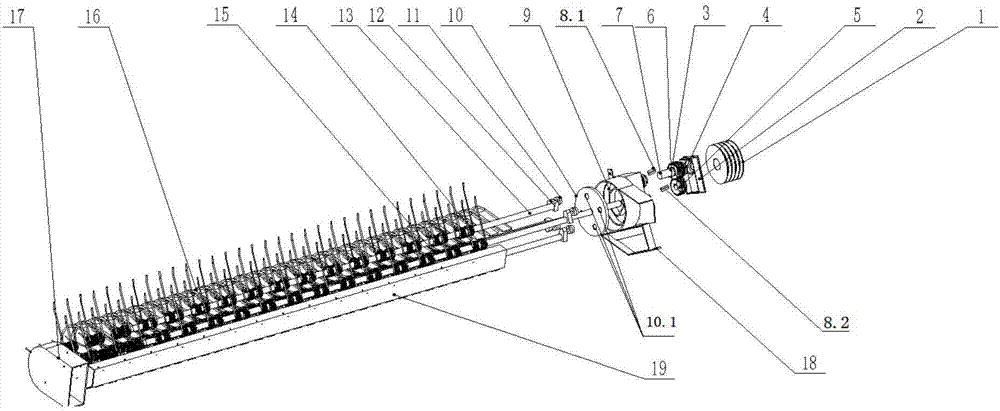

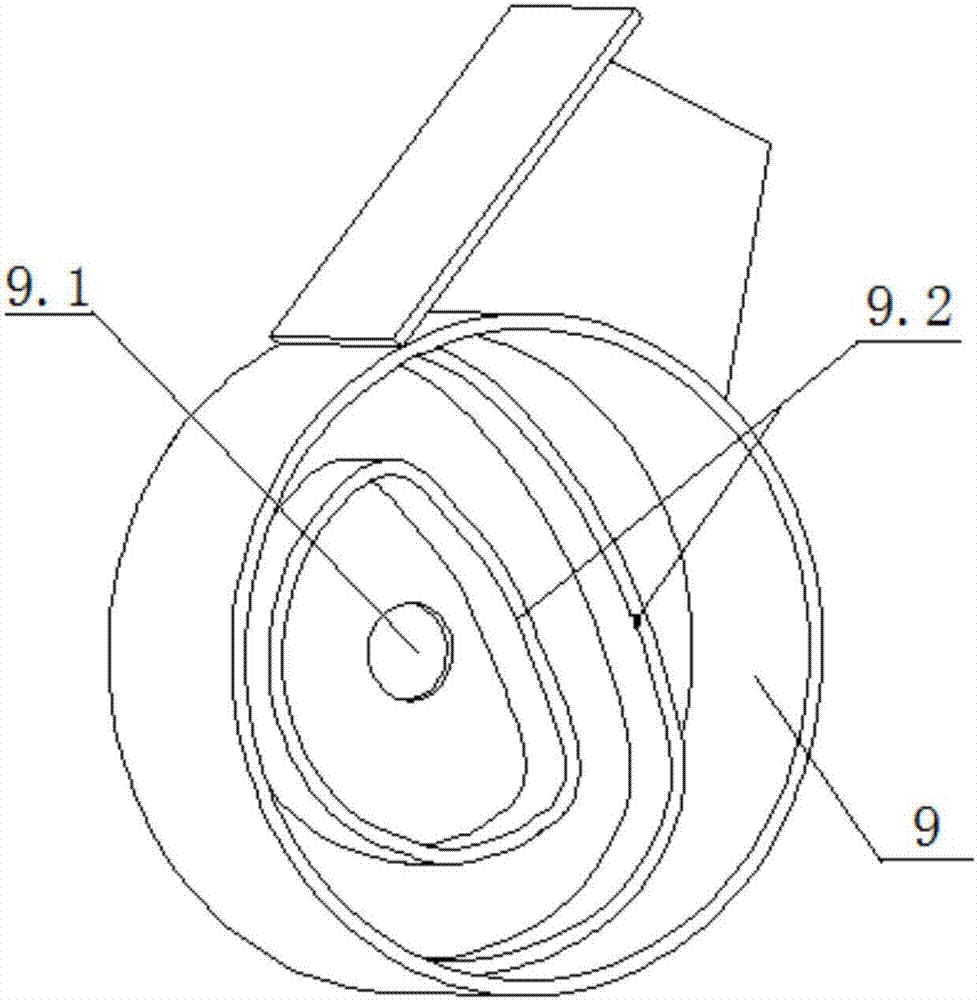

[0073] The invention discloses a pick-up device for a baler with a low missed detection rate, such as figure 1 As shown, it includes a main shaft 15, a spring-toothed roller and a transmission device, and also includes a circular turntable 10 concentrically arranged with the main shaft 15 and a cam 9 (preferably the main shaft 15 is welded to the circular turntable 10), and the cam 9 is fixedly arranged on the guide Rack 18, combined figure 2 It can be seen that a first through hole 9.1 is provided on the cam 9, and a cam track 9.2 is also provided on the cam 9; at the same time, one end of the main shaft 15 passes through the first through hole 9.1 and is fixedly connected with the transmission dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com