Double-glass solar battery packaging method

A technology of solar cells and encapsulation methods, which is applied to circuits, electrical components, semiconductor devices, etc., and can solve the problems of poor anti-exposure and anti-icing performance of solar panels, adverse effects on the performance of solar panels, and inconvenient frame adjustment, etc. Achieve the effects of improving anti-frost and anti-icing performance, good frame packaging and convenient adjustment, and stable packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

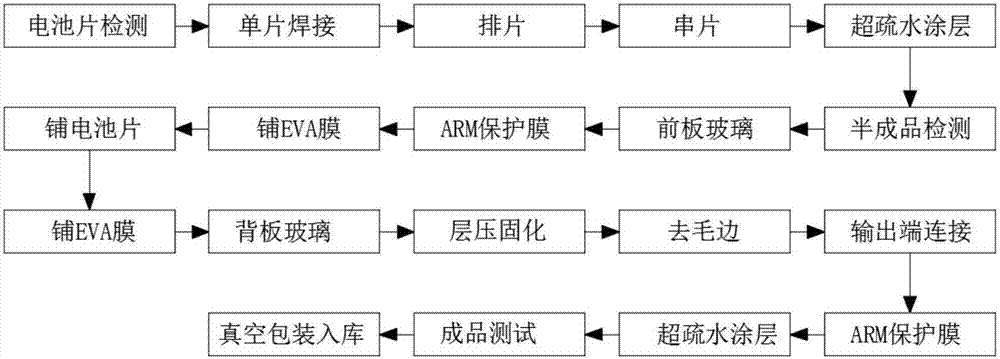

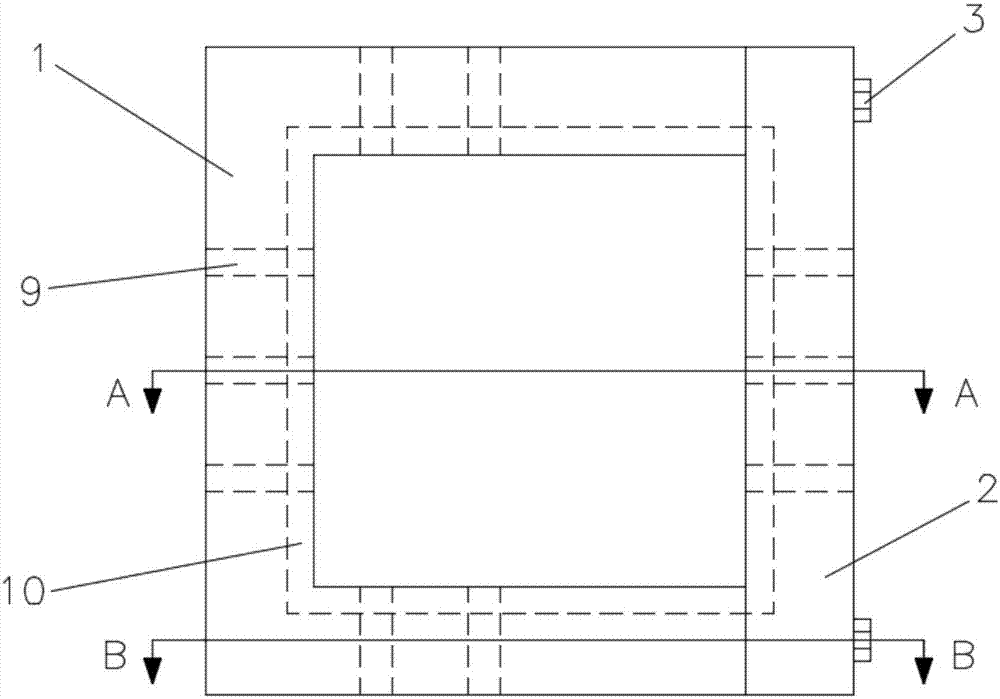

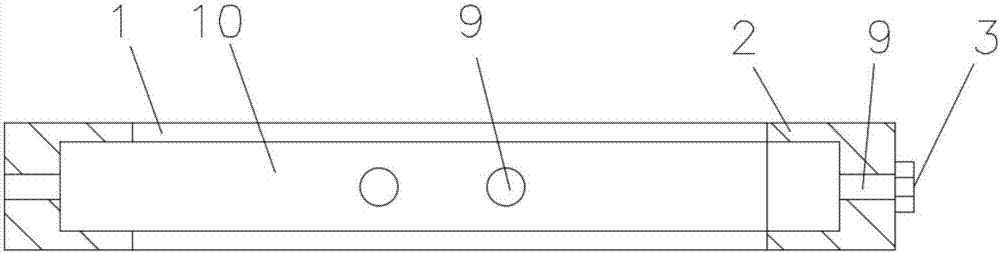

[0032] Example 1, such as Figure 1-4 Shown:

[0033] A double-glass solar cell packaging method, comprising the following packaging steps: (1) cell detection; (2) single cell welding; (3) cell arrangement; (4) cell stringing; A layer of transparent adhesive is arranged on the battery sheet, and a layer of transparent super-hydrophobic coating is coated; (6) semi-finished product inspection; (7) installation of front glass; (8) transparent ARM protective film is pasted on the outer surface of the front glass; ( 9) Laying transparent EVA film on the inner surface of the front glass; (10) Laying battery sheets on the transparent EVA film; (11) Laying transparent EVA film; (12) Installing the back glass; (13) Laminating and curing; (14) ) deburring; (15) output terminal connection; (16) sticking a transparent ARM protective film on the outer surface of the back glass; (17) setting a layer of adhesive on the outer surface of the transparent ARM protective film, and coating a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com