RTP pipe winding equipment and winding method thereof

A technology of equipment and pipes, applied in the field of RTP pipe winding equipment and its winding, can solve problems such as uneven lamination of strips and pipes, influence of pipe structure, pipe deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

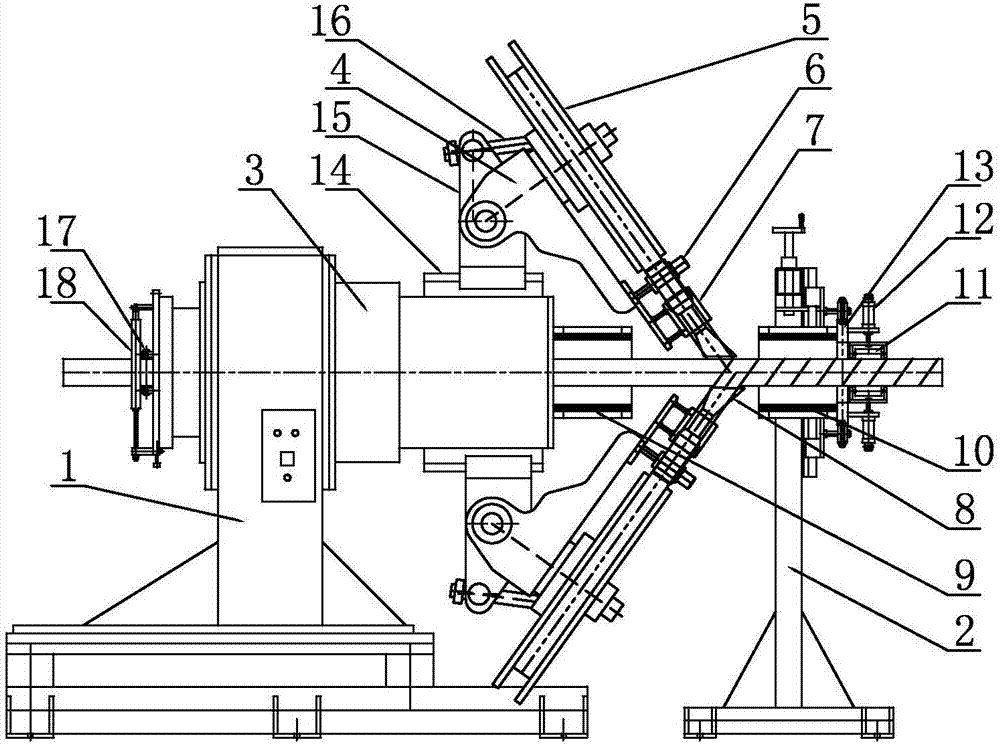

[0018] refer to figure 1 The embodiment of an RTP pipe winding device and its winding method of the present invention will be further described.

[0019] An RTP pipe winding device, comprising a main frame 1 and a side frame 2, the main frame 1 is provided with a rotating base 3 and a main motor for driving the rotating base 3 to rotate, and the center of the rotating base 3 and the side frame 2 are provided with There is a conveying channel for conveying pipe materials, and at least two installation platforms 4 are evenly distributed around the rotation axis on the rotating seat 3, and a belt winding device 5 is provided on the installation platform 4. The disc and the servo motor that drives the belt reel to rotate, the discharge port of the installation platform 4 is provided with a guide wheel 6 and a die opening preheating device 7, the installation platform 4 is also provided with a blowing heating device 8, and the air outlet of the blowing heating device 8 is set At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com