Production method capable of controlling performance difference in thickness direction of super-thick plate

A technology of thickness direction and production method, which is applied in the field of metallurgy, can solve problems such as the performance difference of ultra-thick steel plates, and achieve the effects of strong stress state, improved impact toughness, and prolonged normalizing holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

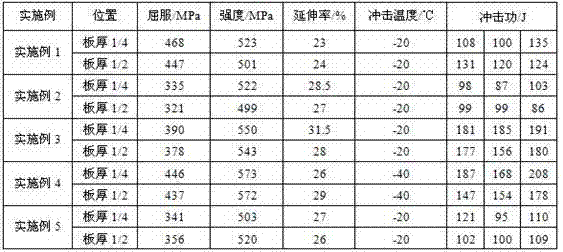

Examples

Embodiment 1

[0019] The production method for controlling the performance difference in the thickness direction of the P295GH steel plate with a thickness of 150 mm includes smelting, die casting, rolling, and heat treatment processes. The specific process steps are as follows:

[0020] (1) Smelting process: The molten steel tapped from the converter enters LF refining, adding 1kg / t steel desulfurizer synthetic slag, the basicity is controlled at 4.0, the P content is 0.004%, and the S content is 0.001%; then VD vacuum treatment is carried out , the vacuum degree is 67Pa, the vacuum treatment time is 45min, after breaking the vacuum, add 1.5kg / t steel Mg-containing Ca-Si core wire, N: 55ppm, O: 10ppm, H: 1.5ppm;

[0021] Synthetic slag is mainly CaO-Al 2 o 3 Alkaline slag system, the composition is: CaO: 50%, Al 2 o 3 : 45%, SiO 2 : 5%; Ca-Si core wire containing Mg, the composition is: Ca: 30%, Si: 50%, Mg: 5%, CaC 2 : 15%;

Embodiment 2

[0027] The production method for controlling the performance difference in the thickness direction of the S355NL steel plate with a thickness of 250 mm includes smelting, die casting, rolling, and heat treatment processes. The specific process steps are as follows:

[0028] (1) Smelting process: The molten steel tapped from the converter enters LF refining, adding 1.5kg / t steel desulfurizer synthetic slag, the basicity is controlled at 5.0, the P content is 0.005%, and the S content is 0.001%; then VD vacuum Treatment, the vacuum degree is 62Pa, the vacuum treatment time is 50min, after breaking the vacuum, add 1.8kg / t steel Mg-containing Ca-Si core wire, N: 40ppm, O: 8ppm, H: 0.5ppm;

[0029] Synthetic slag is mainly CaO-Al 2 o 3 Alkaline slag system, the composition is: CaO: 55%, Al 2 o 3 : 40%, SiO 2 : 4%, FeO: 1%; Ca-Si core wire containing Mg, the composition is: Ca: 35%, Si: 55%, CaC 2 : 10%;

[0030] (2) Die-casting process: during die-casting, the superheat of ...

Embodiment 3

[0035] The production method for controlling the performance difference in the thickness direction of the S355J2+N steel plate with a thickness of 300 mm includes smelting, die casting, rolling, and heat treatment processes. The specific process steps are as follows:

[0036] (1) Smelting process: The molten steel tapped from the converter enters LF refining, adding 1.4kg / t steel desulfurizer synthetic slag, the basicity is controlled at 5.0, the P content is 0.004%, and the S content is 0.001%; then VD vacuum Treatment, the vacuum degree is 60Pa, the vacuum treatment time is 40min, after breaking the vacuum, add 2.5kg / t steel Mg-containing Ca-Si core wire, N: 60ppm, O: 10ppm, H: 1.0ppm;

[0037] Synthetic slag is mainly CaO-Al 2 o 3 Alkaline slag system, the composition is: CaO: 54.5%, Al 2 o3 : 44.5%, FeO: 1%; Ca-Si core wire containing Mg, the composition is: Ca: 30%, Si: 50%, CaC 2 : 20%;

[0038] (2) Die-casting process: during die-casting, the superheat of molten s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com