Plastic runway with foundation made from pervious concrete, and construction method of plastic runway

A technology of permeable concrete and plastic track, which is applied in the field of sports field plastic track and plastic track, which can solve the problems of difficult construction of the base layer, uneven surface, easy rise in temperature, etc., to reduce the heat island effect, not easy to peel off, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

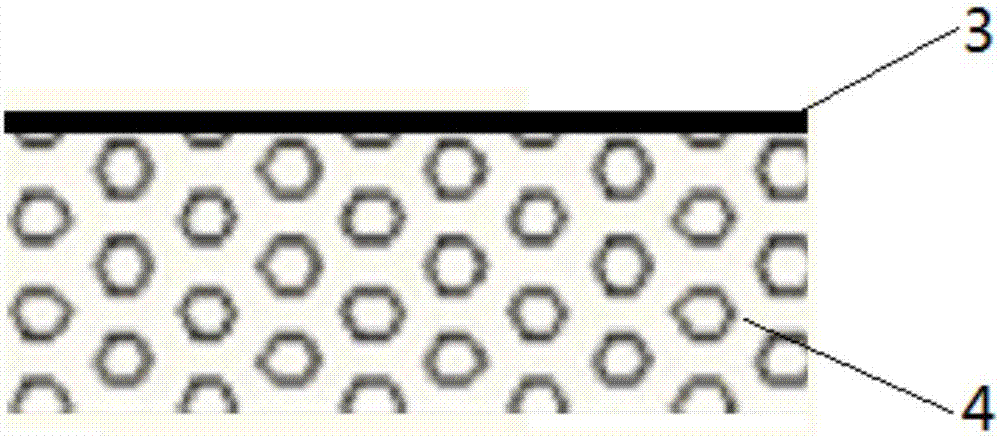

[0032] Such as figure 2 As shown, the foundation adopts the plastic runway of permeable concrete, including the base layer, the base layer 4 and the plastic layer 3 laid on the base layer 4, the base layer 4 is a permeable concrete layer, and the plastic layer 3 and the permeable concrete layer 4 Connected and fixed by glue.

[0033] In this embodiment, the plastic layer 3 includes a hybrid plastic layer or a breathable plastic layer, the glue penetrates into the upper part of the permeable concrete layer 4 to form a glue permeable layer, and the permeable concrete 4 is provided with 10%-25% of pores. The thickness of the glue permeable layer of the permeable concrete is 1.5 mm to 3.5 mm, and the glue permeable layer of the permeable concrete is provided with 5%-15% of pores.

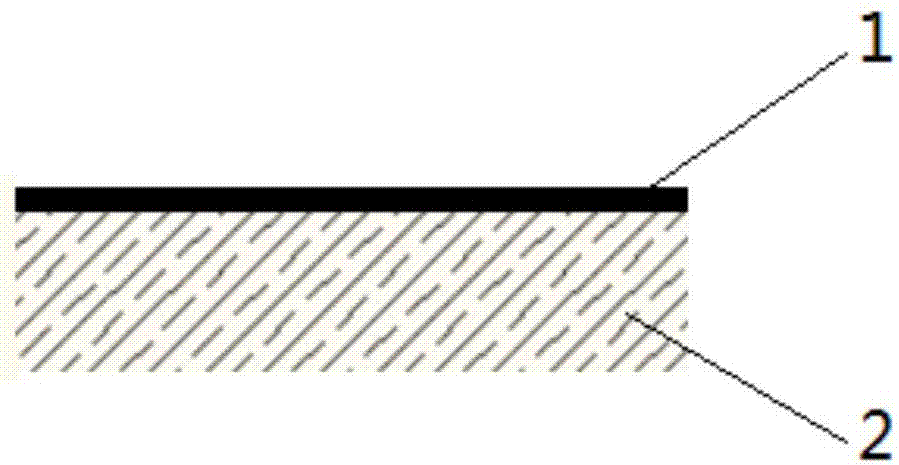

[0034] with attached figure 1 Compared with the traditional plastic track, this embodiment solves the shortcomings of the traditional plastic track that the temperature of the plastic layer is easy t...

Embodiment 2

[0036] A permeable concrete base layer for a plastic runway. The proportion of the permeable concrete is calculated by mass components per cubic meter: 1650kg of sand and gravel, 300-400kg of high-grade Portland cement, 1.5-5kg of environmentally friendly water reducer, Silicon powder 3-10kg, cellulose 0.5-1.5kg, redispersible latex powder 1-3kg, water 100-150kg. In the proportioning of the permeable concrete, 2.5kg of environment-friendly water reducer, 5kg of silica fume, 1kg of cellulose, 2kg of redispersible latex powder, and 120kg of water. The particle size of the sand is 3 mm to 40 mm; the cellulose is cellulose with a viscosity below 100,000 centipoise, and the high-grade portland cement is portland cement with a grade above 600.

Embodiment 3

[0038] A construction technique for a permeable concrete plastic runway, comprising the following steps:

[0039] (1) Fully mix the raw materials required for the base layer of permeable concrete with a forced mixer, send them to the construction site by transport vehicles, pour the base layer of permeable concrete on site, and use up all the raw materials mixed in the same batch within 20 minutes ;

[0040] (2) Carry out manual scraping to the base layer of permeable concrete, and then mechanically polish;

[0041] (3) Check the flatness of the permeable concrete base layer, and level the concave and convex parts;

[0042] (4) Bottom rubber is laid, and the thickness of the rubber particle layer laid by machinery is 10-12 mm; then the surface rubber is paved, and the glue forming speed is uniform when scraping the glue;

[0043] (5) Scraping surface glue, before the surface glue is not cured, sprinkle red particles, and after it is completely cured, clean up the excess surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com