Structured light lighting device and method of producing striped structured light

A structured light illumination and structured light technology, applied in optics, optical components, microscopes, etc., can solve problems such as small illumination field of view, complex optical path structure, and difficult polarization modulation, and achieve the effect of low energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

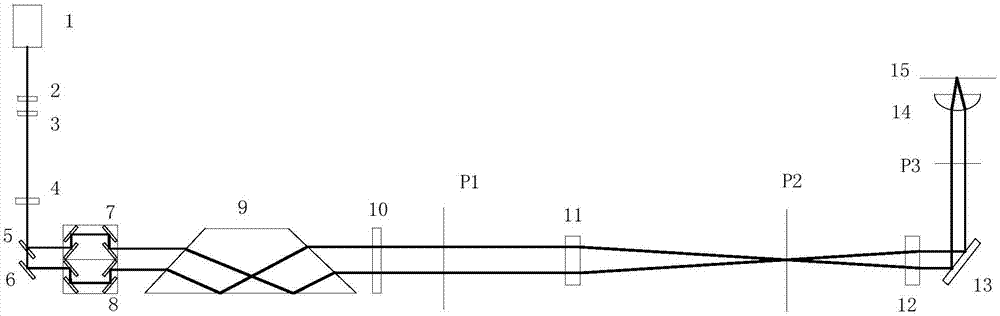

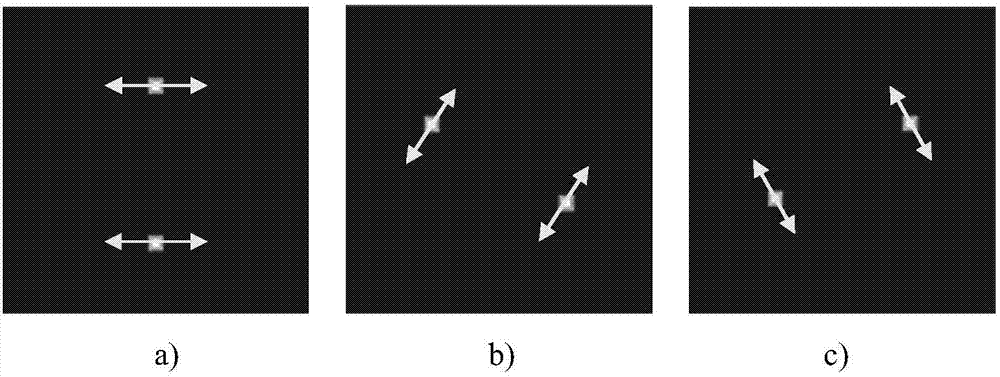

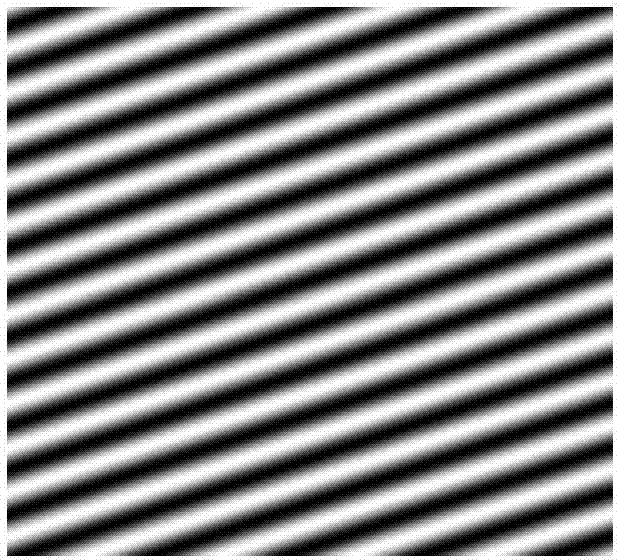

[0032] See figure 1 , figure 1 It is the structured light illumination device provided by the first embodiment of the present invention, which includes: a laser 1, a half-wave plate 2, a condenser lens 4, a beam splitter 5, a reflector 6, an optical path delay module, a Dove prism 9 and a half-wave Plate 10, Dove prism 9 and half-wave plate 10 are rotatably arranged in the optical path; the linearly polarized light emitted by laser 1 sequentially passes through half-wave plate 2 and condenser lens 4, and is divided into reflected beam and transmitted beam by beam splitter 5 light beam; the reflected light beam enters the optical path delay module, and the transmitted light beam is reflected by the mirror 6 to the optical path delay module; the reflected light beam and the transmitted light beam form two illumination beams with the same optical path after passing through the optical path delay module; the two illumination beams After passing through the Dove prism 9 and the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com