Three-dimensional metal palladium nanosheet rapid preparation method based on etching auxiliary growth

A metal palladium and nanosheet technology, applied in the field of nanoscience, can solve problems such as hindering the industrial production and application of three-dimensional metal palladium nanosheets, affecting the catalytic performance of metal palladium catalysts, complex reaction process, etc. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

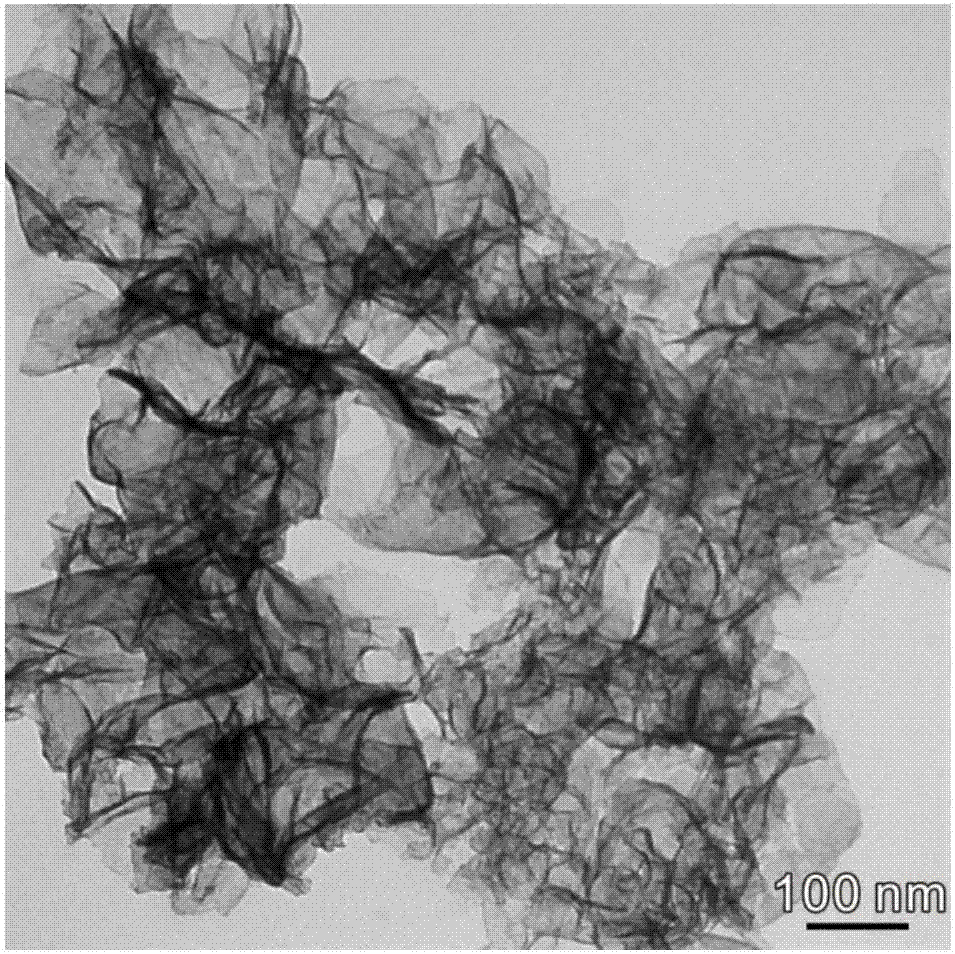

[0041] Embodiment 1: thickness 2.7 nanometers

[0042] (1) 2 mg of sodium chloropalladate was dissolved in 5 mL of water to form a transparent solution;

[0043] (2) Add 0.5mg FeCl to step (1) 3 , stir evenly;

[0044] (3) Pass carbon monoxide (0.3L / min) into step (2), react for 3 minutes, centrifuge, and wash to obtain three-dimensional metallic palladium nanosheets.

Embodiment 2

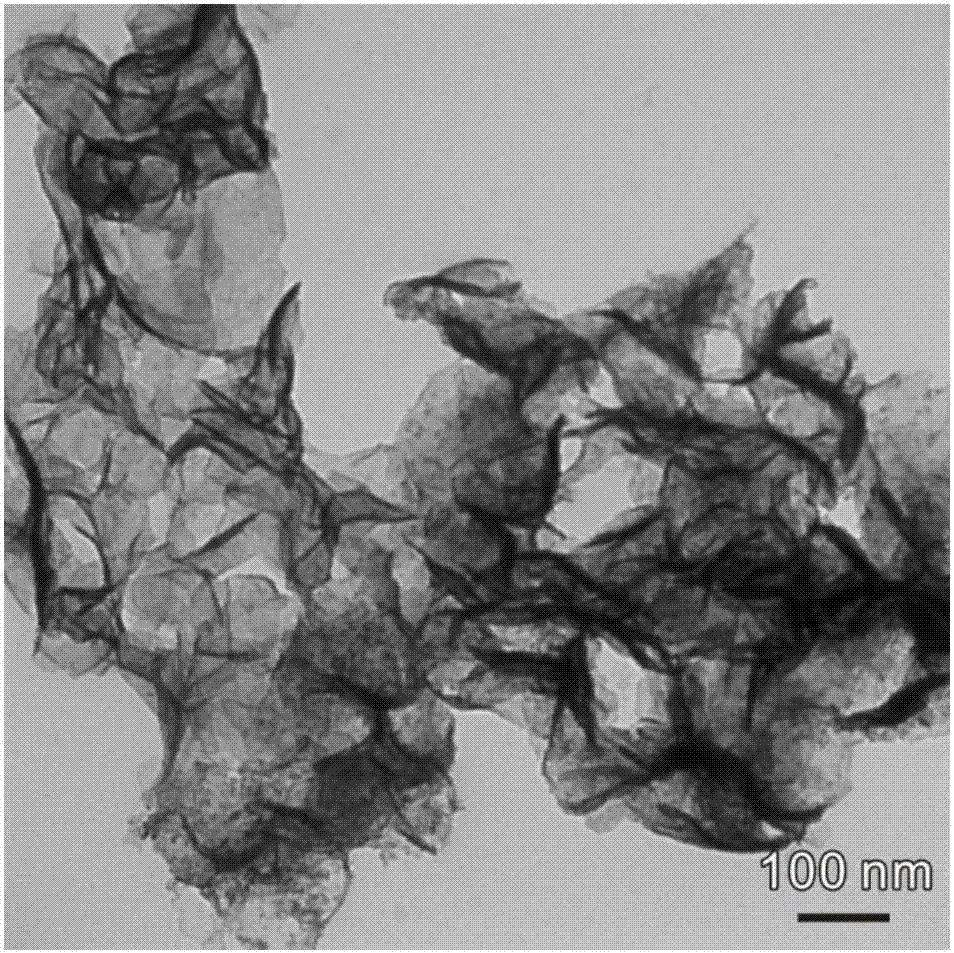

[0045] Embodiment 2: thickness 2.9 nanometers

[0046] (1) 10 mg of sodium chloropalladate was dissolved in 25 mL of water to form a transparent solution;

[0047] (2) Add 2.5mg FeCl to step (1) 3 , stir evenly;

[0048] (3) Pass carbon monoxide (0.3L / min) into step (2), react for 3 minutes, centrifuge, and wash to obtain three-dimensional metallic palladium nanosheets.

Embodiment 3

[0049] Embodiment 3: thickness 2.9 nanometers

[0050] (1) 50 mg of sodium chloropalladate was dissolved in 50 mL of water to form a transparent solution;

[0051] (2) Add 56mg FeCl to step (1) 3 , stir evenly;

[0052] (3) Pass carbon monoxide (0.3L / min) into step (2), react for 15 minutes, centrifuge, and wash to obtain three-dimensional metallic palladium nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com